TITLE

:

DF40 Series Guideline

ETAD-H1015-00

HIROSE ELECTRIC CO.,LTD.

PRODUCT

:

BOARD TO BOARD/FPC CONNECTOR,

Pitch: 0.4mm, Width: 3.38mm,

Stacking height: 1.5-4.0mm

PAGE:

8

OF

18

Copyright© 2007 Hirose Electric Co., Ltd. All rights reserved.

1.2.2 PWB pad layout and connector location

Pad layout and connector position for receptacle

Pad layout and connector position for plug

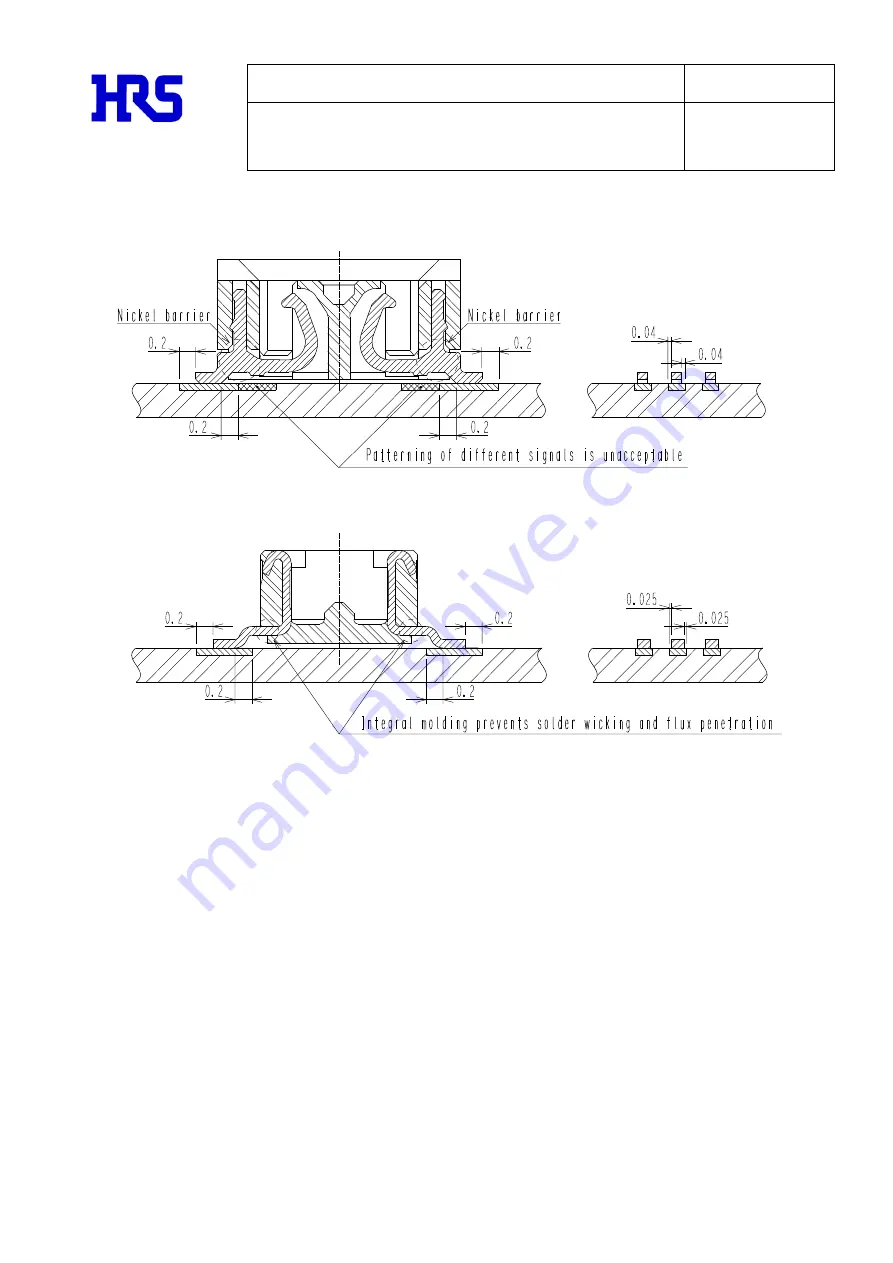

1.2.3 PWB designing

Design PWB layout properly so that front, back and side fillets are formed.

By applying the recommended PWB layout, optimum retention force can be obtained between

connector and PWB.

Solder wicking and flux penetration could occur by applying different PWB layout from the

recommended. Please contact us for the different PWB pattern from the recommended PWB layout.

Although standoff is provided, interference to the connector body by pattern, via hole and solder

resist beneath the connector may cause solder defects and poor fillet formation.

1.2.4 FPC designing

Diversity of coefficient thermal expansion in FPC and stiffener materials may cause FPC warpage and

mounting failure. Confirmation prior to your manufacturing is necessary.

Oct.1.2021 Copyright 2021 HIROSE ELECTRIC CO., LTD. All Rights Reserved.