7

DF57 Series

●

Low Profile “Swing-Lock” Board to Wire Connector for Power

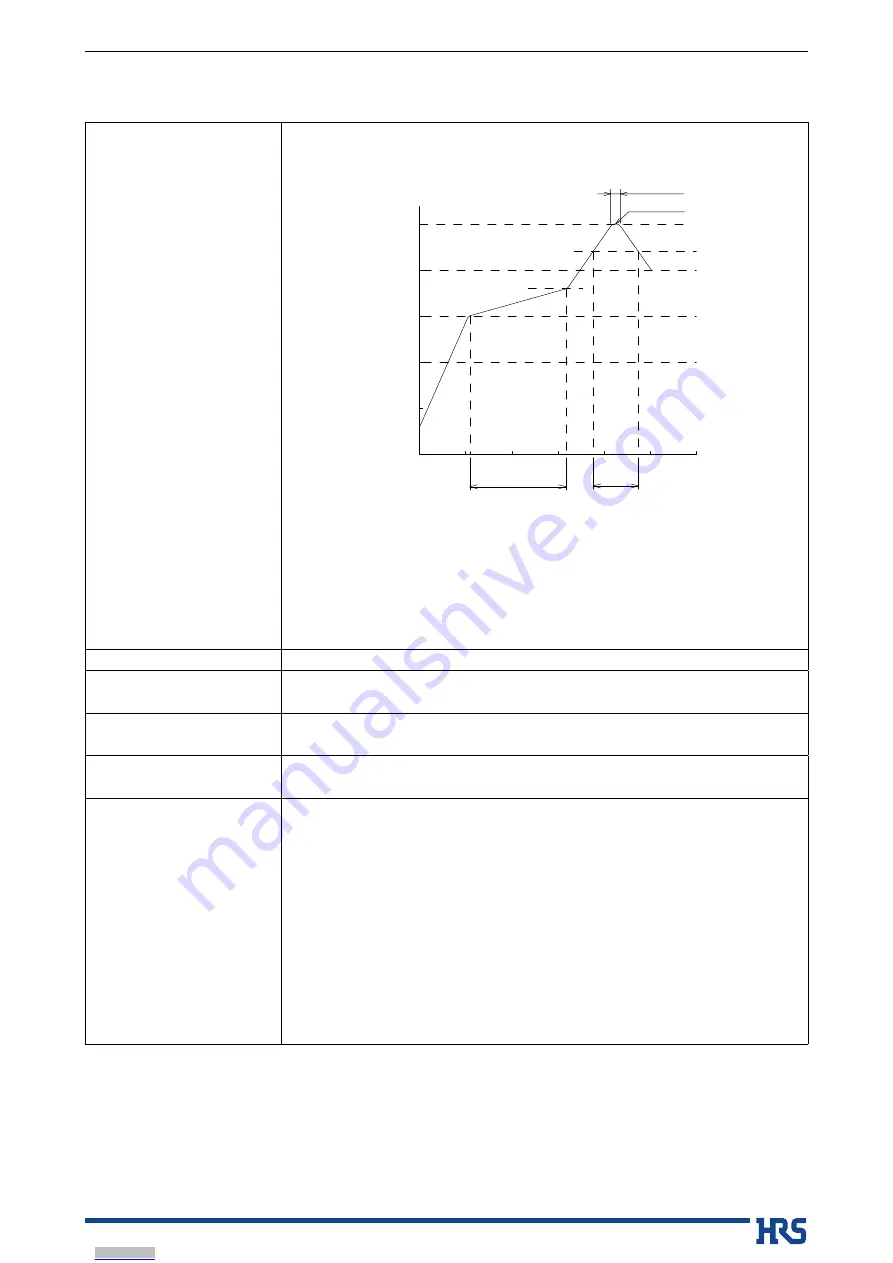

1. Recommended temperature

profi le

The temperature profi les are based on the above conditions.

In individual applications the actual temperature may vary,depending on solder paste type, volume/

thickness and board size/thickness. Consult your solder paste and equipment manufacturer for

specifi c recommendations.

2.Recommended manual soldering

Manual soldering : 350ç ± 10ç for 3 seconds

3. Recommended screen thickness and

open area ratio (Pattern area ratio)

Thickness : 0.1mm

Open area ratio : 100%

4.Board warpage

Maximum of 0.02mm at the connector center, with both ends of the connector as reference points.

5.Cleaning conditions

Cleaning is not recommended. When cleaning, please evaluate as if can deteriorate the

performance including mechanical operation and environmental resistance.

6.Precautions

■

When inserting crimp-type (solderless) terminals to crimping (solderless) sockets, to maintain

reliable performance, please do not insert obliquely.

■

DO NOT mate/un-mate non-terminated plugs with non-mounted receptacles.

This may lead to damage or deformation of the contacts.

■

Removal of the holding electric cable may cause damage so please be careful.

■

DO NOT apply fl ux to the contact terminals when hand soldering the receptacle to the board.

Wicking of the fl ux into the electrical contact areas may lead to connection failures.

■

Slight discoloration on the insulating materials will not affect form, fit or function of the

connectors.

■

Please refer to the documents "DF57 Series Cable assembly Procedure ETAD-H0421", "Crimp

condition" and "DF57-****SCF(A)(**) Crimp quality standards ATAD-H0404" for the cable

assembly procedures.

■

Please refer to the "DF57H Series Mating/Unmating Operation Instruction Manual (ETAD-H0652)"

for the connector operation.

B

Usage Recommendations

TIME (sec)

180ç

100

150

200

250

220ç

PRE-HEATING TIME

SOLDERING TIME

MAX 250ç

90 to 120sec

60secMAX

10secMAX

TEMPERATURE(ç)

0

Dec.1.2019 Copyright 2019 HIROSE ELECTRIC CO., LTD. All Rights Reserved.

Downloaded from

Downloaded from

Downloaded from

Downloaded from

Downloaded from

Downloaded from

Downloaded from