HIROSE ELECTRIC CO.,LTD.

ETAD-H0760

4

9 / 17

FORM HC0011-9-2

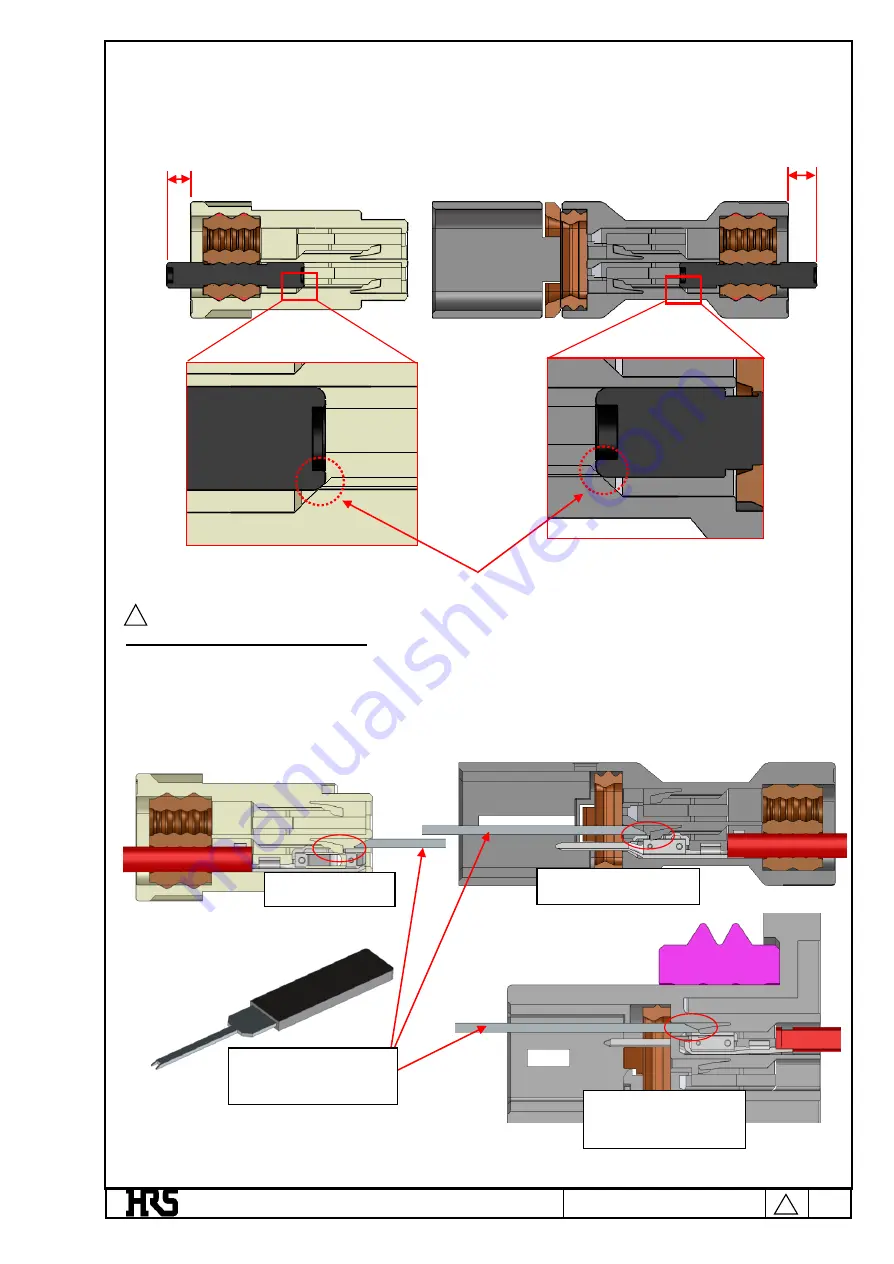

Insert a waterproof pin until it touches crimping socket.

*Insertion more than the target dimension could cause degradation of waterproof

performance.

*To insert the waterproof pin over the target dimension, it has the possibility to fall to a low

level of waterproof.

3.5. Repair of crimped terminal

To remove crimped terminals that have been inserted, pull the cable using the dedicated

Removing jig (DF62W/RE-MD) while pushing up the crimping socket lance.

Using crimping socket after repair could induce decrease of lance strength and / or wire seal

damage. Use new socket to avoid such failures.

Target (1.55 mm)

Target (1.85 mm)

To tap the waterproof pin to socket.

Removing jig

(DF62W/RE-MD)

Socket lance

In-line plug lance

In-line plug lance

(DF62WP)

Figure 3-13. Depth of waterproof pin insertion pin

Figure 3-14. Repair of crimp terminals

①

4