HIROSE ELECTRIC CO.,LTD.

ETAD-H0814-00

2

2 / 6

FORM HC0011-9-2

3. Steps for harnessing

3.1. Cable stripping

Strip cables in accordance with Crimping Quality Standards (ATAD-H0810/0811).

In so doing, make sure there is no scratch on cable cores.

3.2. Crimping

Crimped terminals to cables using an applicator (AP105-DF63-1618-*), and check the crimping

height and shape in accordance with the Table of crimping conditions and Crimping Quality

Standards (ETAD-H0810/0811).

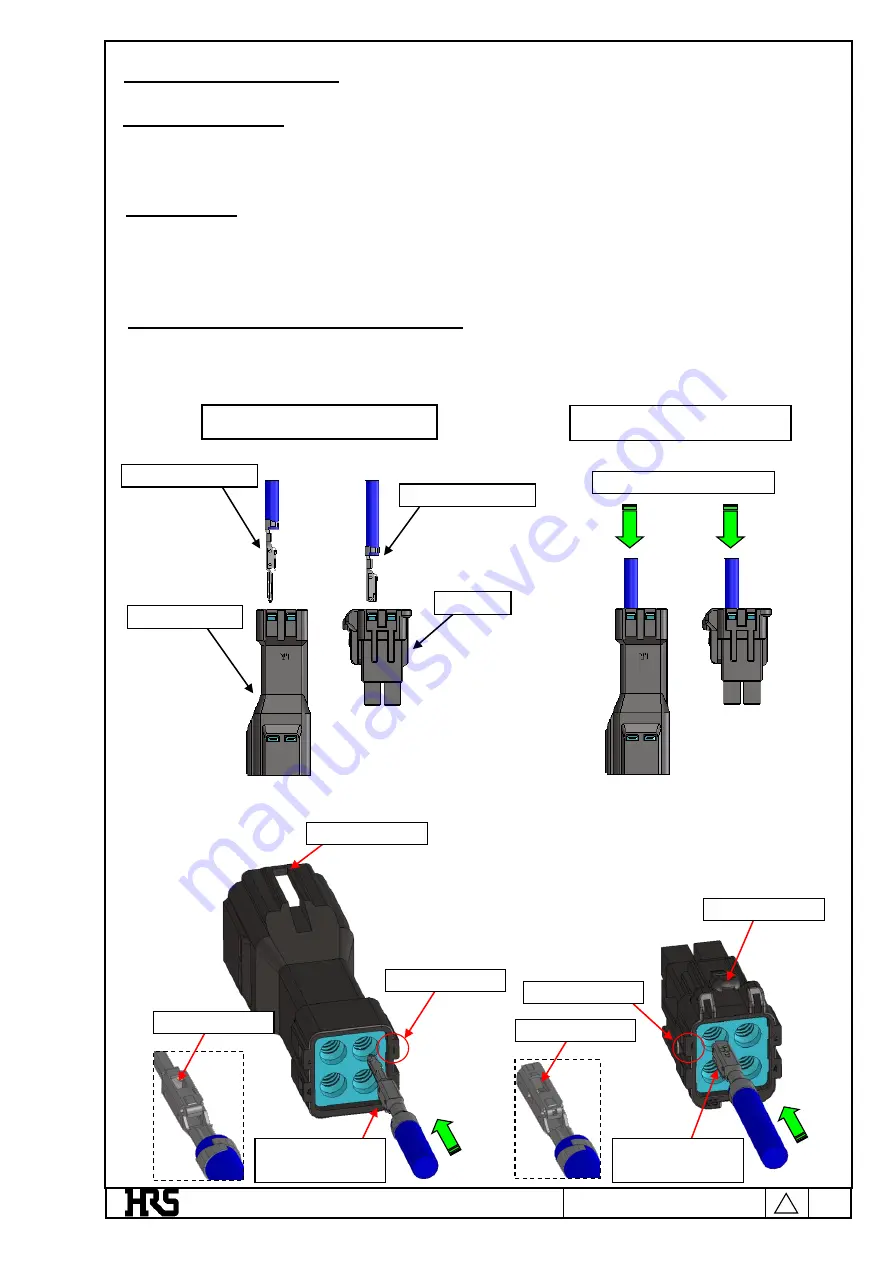

3.3. Insertion to crimping terminal sockets

Hold the cable of a crimped terminal, and insert it to each terminal hole of crimping sockets.

(Insert the terminal in the direction of arrows below.)

*The figures show insertion to DF63W-4EP-3.96C and DF63W-4S-3.96C.

For insertion, place the crimped terminal and crimping socket lock in the following direction:

Before inserting terminal

After inserting terminal

Lanse holder

Lanse holder

Socket

Socket terminal

Plug terminal

In-line Plug

Lock :Upper

Lock :Upper

Contact No.

Contact No.

Lanse holder:

Lower

Lanse holder:

Lower

Direction of insertion

Jun.1.2022 Copyright 2022 HIROSE ELECTRIC CO., LTD. All Rights Reserved.