20

The contents of this catalog are current as of date of 11/2013. Contents are subject to change without notice for the purpose of improvements.

FH12 Series

●

0.5mm and 1mm Pitch Connectors For FPC/FFC

●

Vertical Mounting type (common for 0.5 mm/1 mm pitch)

Operation

Precautions

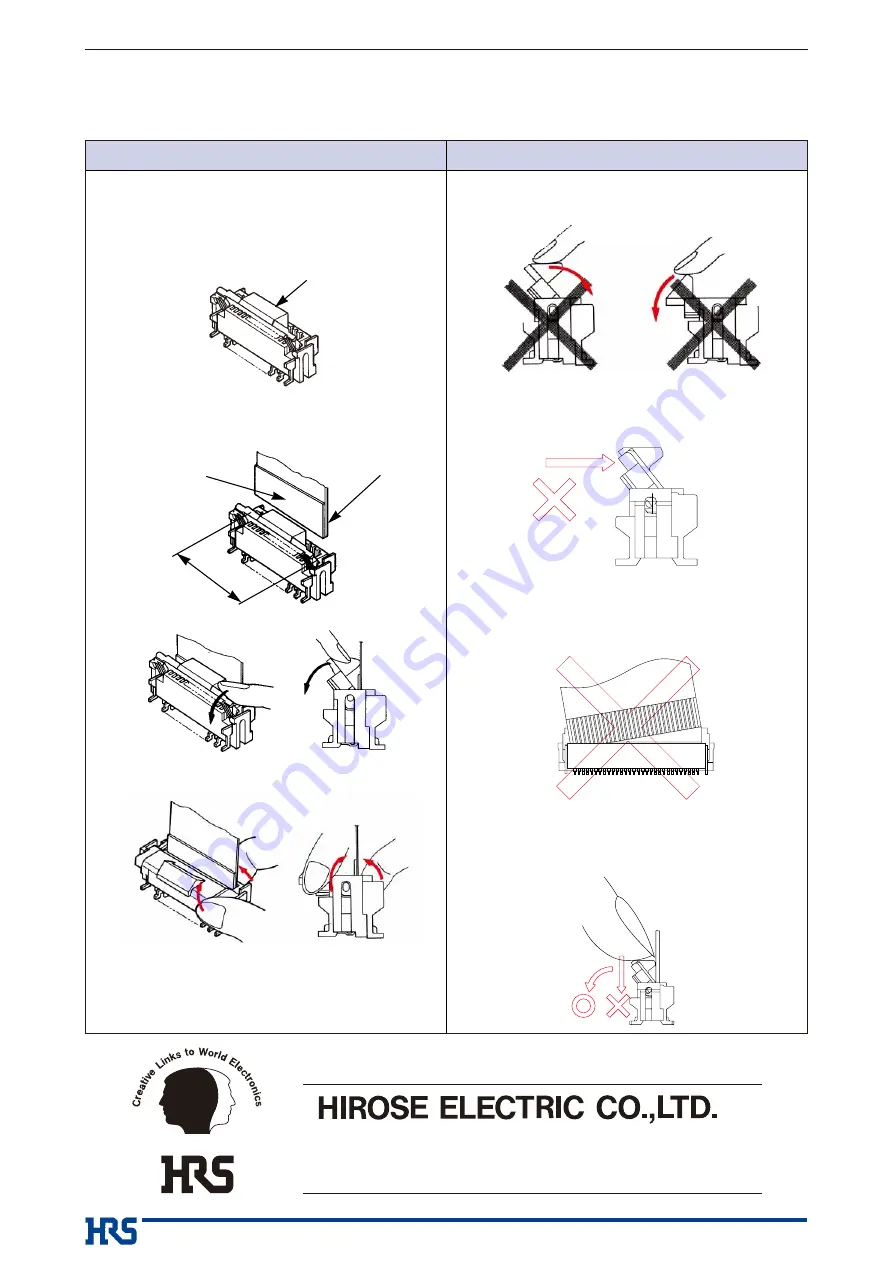

1. FPC/FFC Termination procedure.

Connector installed on the board.

1) Verify that the actuator is positioned upright.

If the actuator has rotated to the side, care-

fully rotate it upright.

2) Insert the FPC/FFC vertically in the connector

slot assuring that the conductive traces of the

FPC/FFC are facing away from the actuator.

1) Avoid forcing the actuator up or down without

the FPC/FFC inserted.

3) Do not insert the FPC/FFC diagonally. Doing so

will result in the corners of the FPC/FFC catching

on the contacts and will cause deformation of the

contacts.

Actuator upright

FPC/FFC conductive traces

Stiffener

Slot

3) Press down the actuator in the direction shown.

2. FPC/FFC Removal

Rotate the actuator upward and withdraw the FPC/FFC.

2) Do not attempt to open or over rotate an already

released actuator (refer to the diagram below).

These actions may damage the actuator.

4) Do not press down vertically on the actuator when

the FPC/FFC already inserted, it needs to be rotat-

ed to engage the lock. Refer to the diagram below.

Doing so may cause actuator failure.

6-3,Nakagawa Chuoh-2-Chome,Tsuzuki-Ku,Yokohama-Shi 224-8540,JAPAN

TEL: +81-45-620-3526 Fax: +81-45-591-3726

http://www.hirose.com

http://www.hirose-connectors.com

®