11

DF13 Series

●

1.25mm Pitch Miniature Crimping Connector (UL Listed)

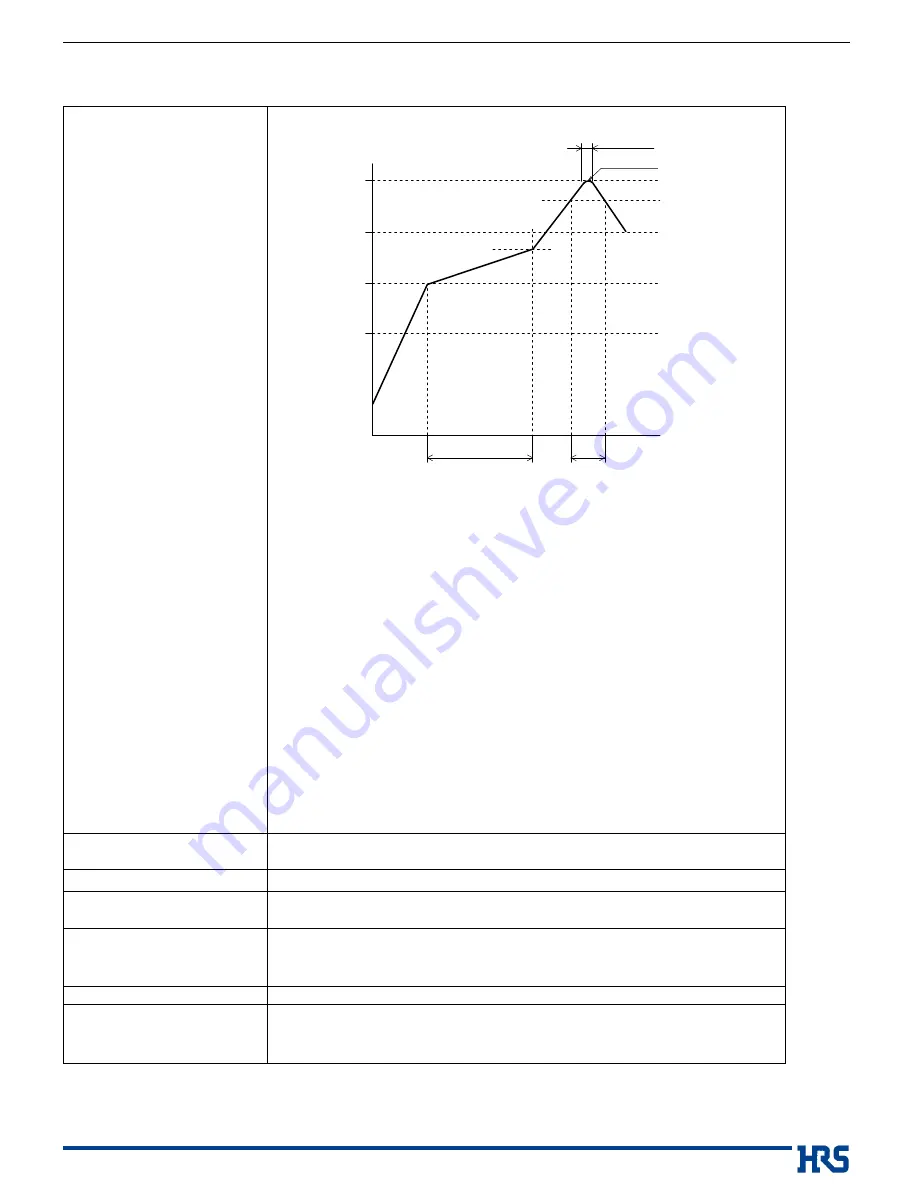

1. Recommended Temperature

Profile (SMT)

Note 1

:

This temperature profile is a recommended value.

Note 2

: Up to 2 cycles of Reflow soldering are possible under the same conditions, provided

that there is a return to normal temperature between the first and second cycle.

Note 3

: The temperature profile indicates the board surface temperature at the point

of contacts with the connector terminals.

Note 4

: Slight variations in color of the plastic compounds do not affect form, fit or function

of the connector.

2. Recommended Screen

Thickness (SMT)

0.15

to

0.2mm

3. Board Warpage (SMT)

Max 0.03mm in the connector center area, based on both connector edges

4. Recommended Manual

Soldering Condition

290±10ç for 2 seconds max.

5. Cleaning Condition

Refer to Wire to board connector Use Hand book.

IPA cleaning is allowed. (Cleaning is not recommended because cleaning may change the

mating/withdrawal feeling etc. Please contact us when you use other cleaning agents.)

6. Cautions

■

Be careful for the excessive scoop insertion/extraction, which will cause damage to the product.

7. Precautions

Please refer to following documents in handling this product.

■

Crimp quality standards (ETAD-H0895-00, ETAD-H0953-00)

■

Wire to board connector Use Hand book.

B

Precautions

MAX 250

℃

TIME(Sec)

60sec MAX

60-120sec

0

100

170

190

℃

230

℃

200

250

10sec MAX

TEMPERATURE

(℃)

PRE-HEATING TIME

SOLDERINGTIME

[Applicable Conditions]

1. Peak temperature : 250

℃

max.

2. Heating area : 230

℃

min. for less than 60 seconds

3. Preheating area : 170

℃

to 190

℃

for 60 to 120 seconds

4. Number of times : no more than 2 times

* Measurement is conducted at the contact lead part

Soldering results may change depending on conditions such as solder paste type,

manufacturer, PCB size, and other soldering materials.

Please determine all mounting conditions before use.

Feb.1.2021 Copyright 2021 HIROSE ELECTRIC CO., LTD. All Rights Reserved.