Maintenance

26

2021-07-07

FM 240 MuW Beta Type S Rev.01

distributed by

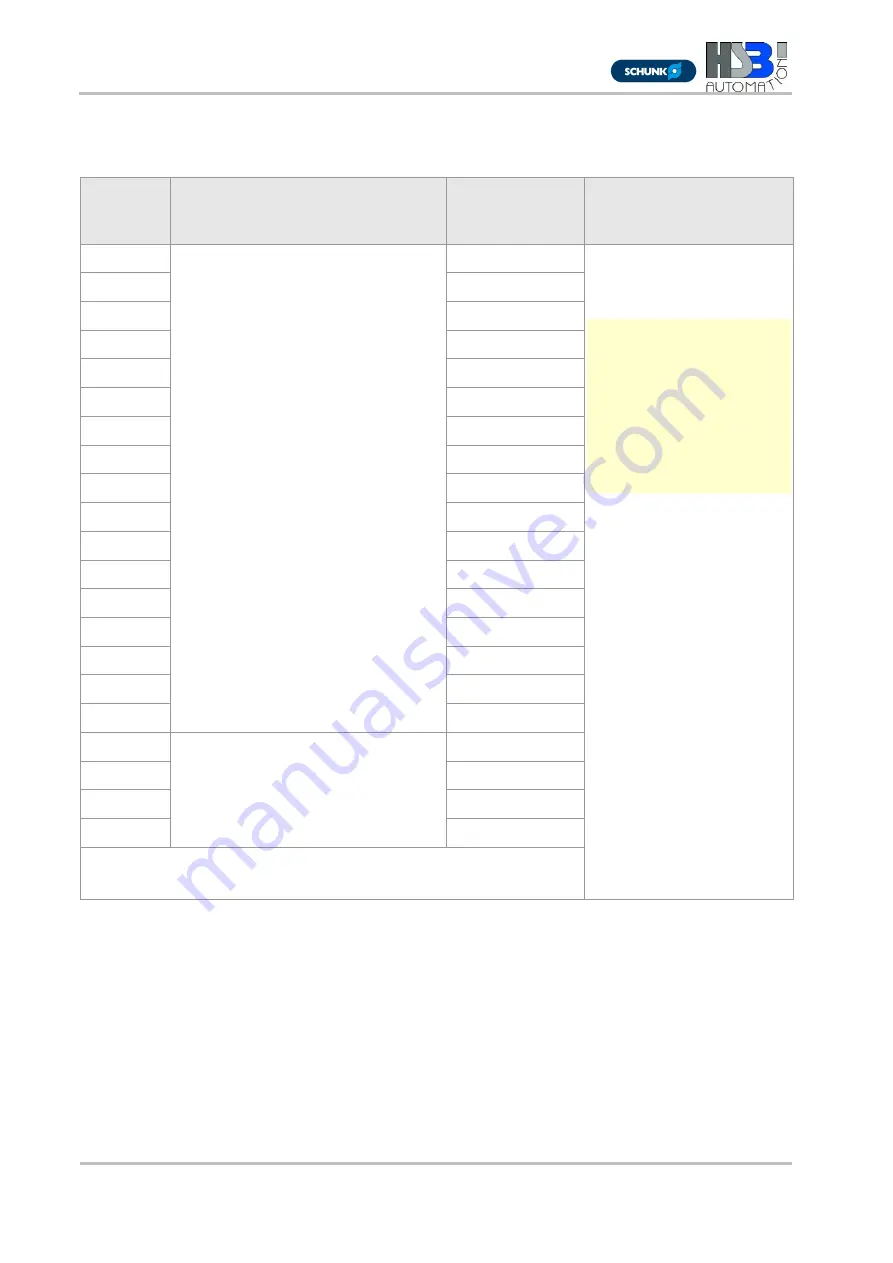

Schedule for lubrication point S (for ball screw drive)

BSD* type

Lubrication intervals at

roll-overs

Grease quantity

[cm³] per ball

screw nut

Grease type

1204

25.000.000**

0,50

Greases to DIN 51825-

KP2N-20, e.g. Klüberplex

BE 31-102

If other greases are

used, pay attention to

manufacturers’

specifications!

Greases containing

solid lubricant (e.g.

graphite, MoS2) must

not be used!

1205

0,55

1605

1,70

1610

1,80

1620

1,90

2005

2,00

2020

2,30

2050

4,50

2505

2,60

2510

3,40

2525

3,10

2550

4,80

3205

4,20

3210

13,10

3220

8,40

3232

5,30

3240

3,00

4005

15.000.000**

5,30

4010

15,40

4020

10,20

4040

9,50

*BSD = Ball Screw Drive

** Or at least 2x per year. The lubrication interval depends on the ambient

temperatures and on the loading (see figure 9

). Relubrication “in motion“!

Summary of Contents for Beta 40-SGS

Page 2: ......