Ⅵ、

OPERATION

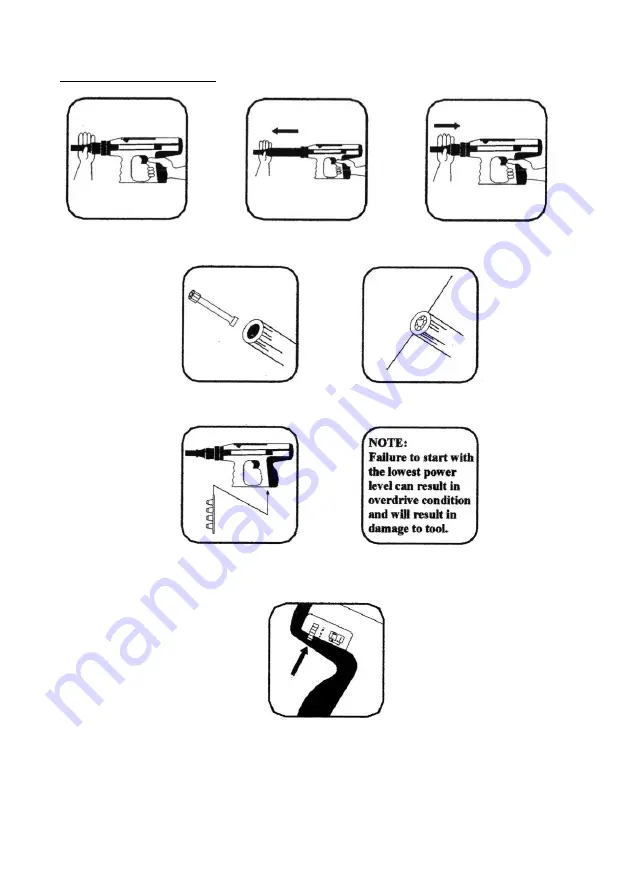

1.Grasp barrel assembly and slide forward rapidly until it stops. Push barrel assembly

back into tool to the closed position. This sets piston into firing position.

2.Insert power fastener into muzzle of tool, head end first. Push the fastener until point is

even with end of tool.

3.

Select the proper power level of power load strips. Always insert power load strips

through bottom of handle. Push power load strip in until even with bottom of handle.

4.

Adjust the fastener driving power by turning the regulating wheel :

1 = min. power

3 = max. power

Start with the min. power. If the fastener does not penetrate deep enough,

increase the driving power.