10

0912

FA 490.1

8 Malfunctions

Check the following before calling customer service:

• Is the power plug connected?

• Is the shredder switched on?

• Is there a paper jam in the shredder?

• Has the motor been overloaded?

Paper jam

You have fed in too much paper.

`

The red LED on the keypad blinks.

`

The cutting block automatically runs in

reverse for several seconds.

Caution!

The blade rollers can still cause injuries

even while they are not running.

Do not reach into the cutting apparatus!

Wear safety gloves!

• Take out the pile of paper.

• Press the green start button and put less

paper on the feed belt.

Electric motor overheated

`

The red LED on the keypad lights up.

`

The shredder switches off automatically.

• Let the motor cool down for 20 - 30

minutes

• Press the green start button.

Safety circuit interrupted

`

The red LED on the keypad lights up.

`

The shredder switches off automatically.

• Check

- Safety

fl

ap on the feed belt is closed.

- The dust tray is pushed in completely.

- (only stand alone-version)

The inspection door is closed.

- (only stand alone-version)

The protective

fl

ap is in vertical position.

• Press the green start button.

Paper dust and particles accumulate in the paper shred-

der during operation. To facilitate cleaning, the ground

plate of the paper shredder was designed as a tray. This

tray must be emptied

every week

.

Note:

The paper shredder cannot be switched on unless the

dust tray is fully pushed in.

Emptying the dust tray

9 Maintenance and care

Cleaning the cutting block

Strip cut machines: (1 x daily)

• Switch off the shredder.

• Squirt special cutting apparatus oil through

the paper feed opening onto the blade rollers.

Order no. 1.235.997.403 for a 250 ml bottle

Order no. 1.235.997.501 for 5 litre container

• Let the cutting apparatus run forwards and

backwards several times without feeding

in any paper.

`

This loosens paper dust and particles.

Cross cut machines:

If the cutting quality de-

teriorates or the machine

becomes noisy:

• Let the shredder run without

feeding in any paper.

• Push the lever of the oiler

down several times.

• Make sure the oil level in

the container is between the

MIN and MAX markings.

Order no. 1.235.997.501 for

5 litre container

MIN

MAX

Summary of Contents for FA 490.1

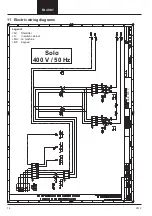

Page 15: ...0912 15 FA 490 1 Solo 400 V ...

Page 16: ...16 0912 FA 490 1 Solo 400 V ...

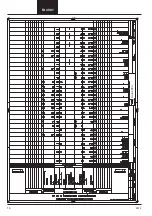

Page 17: ...0912 17 FA 490 1 Kombi 400 V Combination 400 V 50 Hz ...

Page 18: ...18 0912 FA 490 1 Kombi 400 V ...

Page 19: ...0912 19 FA 490 1 Kombi 400 V ...

Page 20: ...20 0912 FA 490 1 Kombi 400 V ...