12

0912

FA 490.1

Tightening the feed belt

The feed belt should not slip when loaded with material.

• Switch off the shredder.

• Remove the feeding table and the left and

right side covers.

• Loosen the hexagon nuts (1) of the tension roll on the

left and right side.

• Loosen the lock nuts (2) of the tensioning bolts (3).

• Tighten the feed belt

evenly

using the tensioning

bolts.

Note:

Only tighten the feed belt until it stops slipping. The feed

belt bearing may be damaged if it is tightened too much.

• Tighten the hex nuts on the snub roller and

the lock nuts on the tensioning bolts again.

Reinstall the covers and the table.

You must check that the feed belt runs

straight:

Switch on the shredder and let it run for

10 minutes. During this time, the feed belt

must run in the middle of the snub roller. If it

slips to the left or right edge, you must alter

the setting of the snub roller.

Checking the feed belt for wear

The surface of the feed belt can become worn after long

periods of use. If you can see the fabric inlay in the belt, it

must be replaced. Please notify our customer service.

1

2

3

Cleaning the shredder:

• Switch off the shredder and disconnect the mains

plug.

• When cleaning, only use a soft cloth and a mild soap-

water solution. Never use scouring agents, cleaning

fl

uid, petroleum or thinners.

Cleaning the tensioning station (monthly)

• Remove the feeding table and the front panel of the

tensioning station.

• Remove particles and dirt.

Cleaning the conveyor-belt area (monthly)

• Remove the covers on both sides.

The cleaning openings in the conveyor-belt covers are

now accessible.

• Blow out the conveyor-belt area with compressed air

or use a vacuum cleaner to remove the dirt particles.

Checking the stripping brush (monthly)

• Remove the covers on both sides.

The stripping brush below the conveyor belt is now

accessible.

If the stripping brush is not

fl

ush with the conveyor

belt, you must re-adjust the stripping brush:

• Loosen the brush supports on the left and on the right.

• Re-adjust the brush support with the brush upwards.

• Screw the brush support back on.

Summary of Contents for FA 490.1

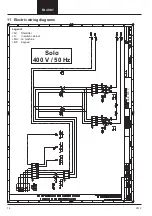

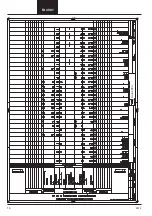

Page 15: ...0912 15 FA 490 1 Solo 400 V ...

Page 16: ...16 0912 FA 490 1 Solo 400 V ...

Page 17: ...0912 17 FA 490 1 Kombi 400 V Combination 400 V 50 Hz ...

Page 18: ...18 0912 FA 490 1 Kombi 400 V ...

Page 19: ...0912 19 FA 490 1 Kombi 400 V ...

Page 20: ...20 0912 FA 490 1 Kombi 400 V ...