Summary of Contents for HSM FA 500.2

Page 15: ...1002 15 FA 500 2 Solo 400 V http www monomachines com http www monomachines com ...

Page 16: ...16 1002 FA 500 2 Solo 400 V http www monomachines com http www monomachines com ...

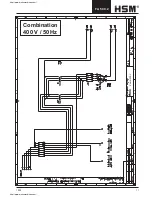

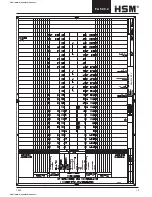

Page 18: ...18 1002 FA 500 2 Kombi 400 V http www monomachines com http www monomachines com ...

Page 19: ...1002 19 FA 500 2 Kombi 400 V http www monomachines com http www monomachines com ...

Page 20: ...20 1002 FA 500 2 Kombi 400 V http www monomachines com http www monomachines com ...