MANUAL

HK2 – HK4 25-08-2014

Page

25

3.6

Adjustment of temperature settings, sensor location

The temperature settings are factory made and are normally not to alter. However, a control

of the factory settings before servicing is advisable and as well a sensor control.

Boilers water sensor:

The role is the same as a temperature-limiting thermostat. It stops the

suction fan before the safety thermostat or the hydraulic safety cooling

system is activated.

Boilers factory settings: 87°C (maximum position) – fan shuts out at 90 °C.

Flue gas sensor:

The role is to stop the suction fan and recycling pump when the

combustion ends. The switch off happens when the flue gas temperature

decreases below the minimum flue gas setting value.

Minimum flue gas temperature factory setting: 90 °C.

In which case can an adjustment become necessary?

The boiler temperature can exceptionally decrease to 85°C, if at 90°C (of boiler water) either

the safety thermostat shots off the boiler and/or the temperature safety valve has already

began to open.

The amount of embers in the bottom of the loading chamber is insufficient after the fan has

stopped; the minimum flue gas temperature can be adjusted to make the amount of ember

sufficient for an easy startup for the next firing. In some cases (low fuel quality, chimneys

draught not easy to stabilize...) it can be useful to change the factory setting. Proceed like

below:

-

When the suction fan stops: if there is no embers at all: set to 110 °C – 120 °C.

-

When the suction fan stops, there is too much embers, covering the entire bottom of the

loading chamber: set 85°C, or 80°C.

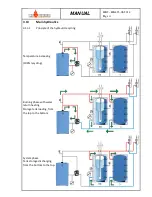

Flue gas sensor

Boilers sensor and STB

Summary of Contents for HK2

Page 27: ...MANUAL HK2 HK4 25 08 2014 Page 27 3 8 Electrical connections ...

Page 33: ...MANUAL HK2 HK4 25 08 2014 Page 33 No text ...

Page 34: ...MANUAL HK2 HK4 25 08 2014 Page 34 No text ...

Page 35: ...MANUAL HK2 HK4 25 08 2014 Page 35 No text ...

Page 36: ...MANUAL HK2 HK4 25 08 2014 Page 36 Rev 02 010914 ...