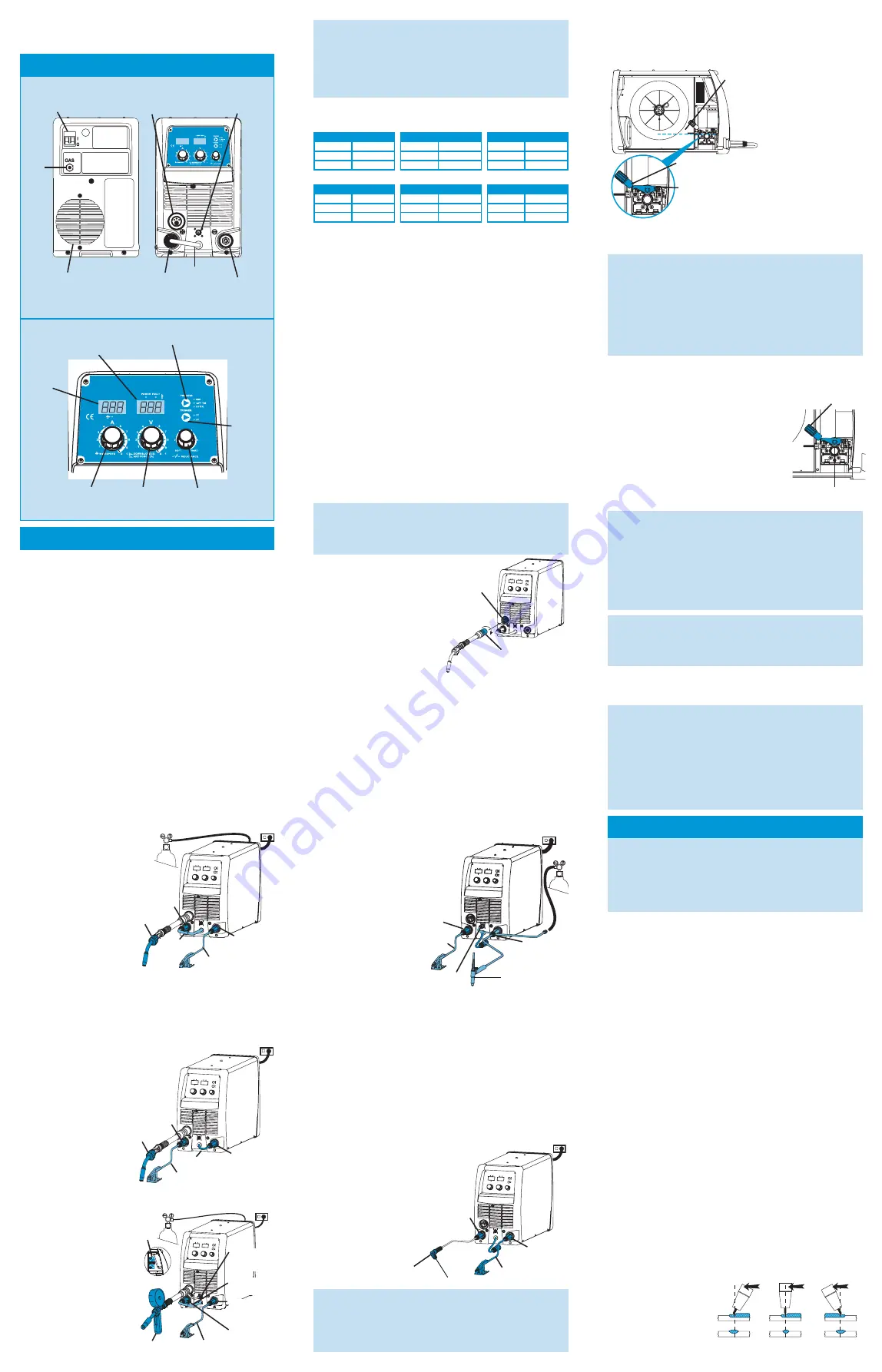

IDENTIFIER

The ON/OFF switch

(front panel)

is the main circuit

breaker. The Power Indicator display illuminates when

the power switch is in the ON position.

Amperage/

Wirespeed

switch

Voltage

switch

Process Selection

Control

Arc Control

(Inductance)

switch

Digital

Amps

Meter

Digital

Voltage

Meter

Trigger

Mode

Control

MIG

Gun

Adaptor

Positive

Welding

Output

Terminal

MIG

Polarity

Lead

Negative

Welding

Output

Terminal

Remote

Control

Socket

Gas

Inlet

Cooling

Fan

On / Off

Switch

GETTING STARTED

It is important that the equipment duty cycle is taken

into consideration when in use.

This welding power source is protected by a self resetting

thermostat. The indicator will illuminate if the duty cycle of

the power source has been exceeded. Should the thermal

overload indicator illuminate the output of the power

source will be disabled. Once the power source cools down

this light will go OFF and the over temperature condition

will automatically reset. Note that the mains power switch

should remain in the on position such that the fan

continues to operate thus allowing the unit to cool

sufficiently. Do not switch the unit off should a thermal

overload condition be present.

TRANSPORTING METHODS

This unit is equipped with a handle for carrying purposes.

Lift unit with handles built into the top of the front and rear

moulded panels.

Use handcart or similar device of adequate capacity.

If using a fork lift vehicle, place and secure unit on a proper

skid before transporting.

PREPARING FOR WORK

Place the unit on the

stable, levelled ground at a distance

of 300mm or more from the walls or similar that could

restrict natural air flow for cooling. Make sure the area

is free from moisture, dust, oil, steam and corrosive

gases. It is important to operate the machine in ambient

temperature between

0o C and 40o C.

ATTACHING MIG GUN

Fit the MIG gun to the

power source by pushing

the MIG gun connector into

the MIG gun adaptor and

screwing the plastic nut

clockwise to secure the MIG

gun to the MIG gun

adaptor.

WARNING

WELDING PRODUCTS AND WELDING PROCESSES CAN

CAUSE SERIOUS INJURY OR DEATH, OR DAMAGE TO

OTHER EQUIPMENT OR PROPERTY, IF THE OPERATOR

DOES NOT STRICTLY OBSERVE ALL SAFETY RULES

AND TAKE PRECAUTIONARY ACTIONS.

140A

20%

99A

60%

77A

100%

MIG DUTY CYCLE

125A

20%

80A

60%

60A

100%

STICK DUTY CYCLE

200A

20%

130A

60%

101A

100%

TIG DUTY CYCLE

DANGER!

ALWAYS MAKE SURE THE MAINS POWER SUPPLY IS

SWITCHED OFF BEFORE UNDERTAKING ANY TYPE OF

INTERVENTION ON THE WELDER

The HSS 200 amp Mig Welder is a self contained single

phase multi process welding inverter that is capable of

performing MIG (GMAW/FCAW), STICK (MMA) and LIFT TIG

(GTAW) welding processes. The unit is equipped with an

integrated wire feed unit, digital voltage and amperage

meters, and a host of other features in order to fully satisfy

the broad operating needs of the modern welding

professional.

Never use the 200 amp Mig Welder until you have fully

read and understood this User Guide and the machine has

been properly set up

using the information it contains.

MIG Gun

Adaptor

MIG Gun

Connector

INSERTING WIRE INTO THE WIRE FEED MECHANISM

Release the tension from the pressure roller by turning the

adjustable wire drive tension screw in an anti-clockwise

direction. Then to release the pressure roller arm push

the tension screw

toward the front of the

machine which

releases the pressure

roller arm. With the

MIG welding wire

feeding from the

bottom of the spool

pass the electrode wire

through the inlet guide, between

the rollers, through the outlet

guide and into the MIG gun. Re-

secure the pressure roller arm and

wire drive tension screw and adjust

the pressure accordingly. Remove

the contact tip from the MIG gun. With the MIG gun lead

reasonably straight, feed the wire through the MIG gun by

depressing the trigger switch. Fit the appropriate contact tip.

FEED ROLLER PRESSURE ADJUSTMENT

The pressure (top) roller applies pressure to the grooved

feed roller via an adjustable pressure

screw. These devices should be adjusted

to a minimum pressure that will provide

satisfactory WIREFEED without slippage. If

slipping occurs, and inspection of the wire

contact tip reveals no wear, distortion or

burn back jam, the conduit liner should be

checked for kinks and clogging by metal

flakes and swarf. If it is not the cause of

slipping, the feed roll pressure can be

increased by rotating the pressure screw

clockwise.

MIG Welding

Wire

DANGER!

BEFORE CONNECTING THE WORK CLAMP TO THE

WORK MAKE SURE THE MAINS POWER SUPPLY IS

SWITCHED OFF.

THE WELDING WIRE WILL BE AT WELDING VOLTAGE

POTENTIAL WHILE IT IS BEING FEED THROUGH THE

SYSTEM.

KEEP MIG GUN AWAY FROM EYES AND FACE.

Wire Drive

Tension Screw

Pressure Roller

Arm

Wire Drive

Tension

Screw

Pressure

Roller Arm

MIG (GMAW) WELDING WITH GAS SHIELDED MIG WIRE

The process selection control is used to select the desired

welding mode. Three modes are available, MIG

(GMAW/FCAW), LIFT TIG (GTAW) and STICK (MMA) modes.

Note that when the unit is powered off the mode selection

control will automatically default to MIG mode. This is

necessary so as to prevent inadvertent arcing should an

electrode holder be connected to the unit and mistakenly be

in contact with the work piece during power up.

MIG (GMAW) WELDING WITH GAS SHIELDED MIG WIRE

Select MIG mode with the

process selection control.

Next, connect the MIG

polarity lead to the positive

welding terminal (+).

Fit the MIG gun to the

power source.

Connect the work lead to

the negative welding

terminal (-).

Fit the welding grade

shielding gas regulator /

flow meter to the

shielding gas cylinder, then connect the shielding gas hose

from the rear of the power source to the regulator /

flowmeter outlet.

Refer to the Weld Guide located on the inside of the wirefeed

compartment door for further information.

MIG (FCAW) WELDING WITH GASLESS MIG WIRE

Select MIG mode with the

process selection control.

Connect the MIG polarity

lead to the negative

welding terminal (-).

Connect the work lead to

the positive welding

te).

Refer to the Weld Guide

located on the inside of the

wirefeed compartment

door for further

information.

SPOOL GUN MIG (GMAW) WELDING WITH GAS

SHIELDED MIG WIRE

Select MIG mode with the

process selection control.

Connect the MIG polarity

lead to the positive

welding te).

Fit the Euro Spool Gun to

the power source using

the front panel EURO

adaptor (see Attaching

MIG gun). Connect the 8

pin Remote Control Plug

to the 8 pin Remote

DANGER!

BEFORE CONNECTING THE WORK CLAMP TO THE

WORK MAKE SURE THE MAINS POWER SUPPLY IS

SWITCHED OFF.

SECURE THE WELDING GRADE SHIELDING GAS

CYLINDER IN AN UPRIGHT POSITION BY CHAINING IT

TO A SUITABLE STATIONARY SUPPORT TO PREVENT

FALLING OR TIPPING.

Positive

Welding

Terminal (+)

MIG Polarity

Lead

Negative

Welding

Terminal (-)

Work Lead

MIG Gun

CAUTION!

LOOSE WELDING TERMINAL CONNECTIONS CAN

CAUSE OVERHEATING AND RESULT IN THE MALE

PLUG BEING FUSED IN THE TERMINAL.

Positive

Welding

Terminal (+)

MIG

Polarity

Lead

Negative

Welding

Terminal (-)

Work Lead

MIG Gun

Control Socket on the power source.

Connect the work lead to the negative welding terminal(-).

Fit the welding grade shielding gas regulator / flowmeter to

the shielding gas cylinder, then connect the shielding gas

hose from the rear of the power source to the regulator /

flowmeter outlet.

Refer to the Weld Guide located on the inside of the wirefeed

compartment door for further information.

Select MIG mode with the process selection control.

Set the Spool Gun Switch located inside the wire drive

compartment, to SPOOL GUN.

TIG (GTAW) WELDING

Select LIFT TIG mode with

the process selection

control.

Connect the TIG Torch to

the negative welding

terminal (-).

Connect the work lead to

the positive welding

terminal (+).

Connect the TIG torch

trigger switch via the 8 pin

socket located on the front

of the power source as

shown below. The TIG torch will require a trigger switch to

operate in LIFT TIG Mode.

NOTE: If the TIG torch has a remote TIG torch current control

fitted then it will require to be connected to the 8 pin socket.

Fit the welding grade shielding gas regulator/flowmeter to

the shielding gas cylinder (see MIG Welding With Gas

Shielded Mig Wire) then connect the shielding gas hose from

the TIG torch to the regulator/flowmeter outlet. Note that the

TIG torch shielding gas hose is connected directly to the

regulator/flowmeter. The power source is not fitted with a

shielding gas solenoid to control the gas flow in LIFT TIG

mode therefore the TIG torch will require a gas valve.

STICK (MMA) WELDING

Connect the Electrode

Holder lead to the positive

welding te).

Connect the work lead to

the negative welding

terminal (-). Select STICK

mode with the process

selection control.

DANGER!

BEFORE INSERTING THE ELECTRODE IN THE TIG

TORCH MAKE SURE THE MAINS POWER SUPPLY IS

SWITCHED OFF.

BASIC TECHNIQUES

MIG WELDING

The easiest welding procedure for the beginner to

experiment with MIG welding is the flat position. The

equipment is capable of flat, vertical and overhead positions.

For practicing MIG welding, secure some pieces of 1.6mm or

1.2mm mild steel plate 150 x 150mm. Use 0.8mm flux cored

gasless wire or a solid wire with shielding gas.

Begin work by setting up power source. Power source has

two control settings that have to balance. These are the

Wirespeed control and the welding Voltage Control. The

welding current is determined by the Wirespeed control, the

current will increase with increased Wirespeed, resulting in a

shorter arc. Less wire speed will reduce the current and

lengthen the arc. Increasing the welding voltage hardly alters

the current level, but lengthens the arc. By decreasing the

voltage, a shorter arc is obtained with a little change in

current level.

When changing to a different electrode wire diameter,

different control settings are required. A thinner electrode

wire needs more Wirespeed to achieve the same current

level.

A satisfactory weld cannot be obtained if the Wirespeed and

Voltage settings are not adjusted to suit the electrode wire

diameter and the dimensions of the work piece.

If the Wirespeed is too high for the welding voltage,

“stubbing” will occur as the wire dips into the molten pool

and does not melt. Welding in these conditions normally

produces a poor weld due to lack of fusion. If, however, the

welding voltage is too high, large drops will form on the end

of the wire, causing spatter. The correct setting of voltage

and Wirespeed can be seen in the shape of the weld deposit

and heard by a smooth regular arc sound. Refer to the Weld

Guide located on the inside of the wirefeed compartment

door for setup information.

The angle of MIG gun to

the weld has an effect

on the width of the

weld. The welding gun

should be held at an

angle to the weld joint.

Hold the gun so that the welding seam is viewed at all times.

ADVICE

IF YOU HAVE NOT YET DONE ANY WELDING,

PRACTICE ON A PIECE OF SCRAP PLATE BEFORE

GOING ON TO MORE SERIOUS WORK. YOU MAY AT

FIRST EXPERIENCE DIFFICULTY.

ATTENTION

IF IN DOUBT, WHEN CONNECTING THE WORK LEAD

CONTACT HSS HIRE FOR ADVICE

WELDING CURRENT FLOWS FROM THE POWER

SOURCE VIA HEAVY DUTY BAYONET TYPE

TERMINALS. IT IS ESSENTIAL, HOWEVER, THAT THE

MALE PLUG IS INSERTED AND TURNED SECURELY TO

ACHIEVE A SOUND ELECTRICAL CONNECTION.

Positive

Welding

Terminal (+)

Negative

Welding

Terminal (-)

Work Lead

Electrode Holder

Positive

Welding

Terminal

(+)

Negative

Welding

Terminal (-)

TIG Remote

Control

TIG Torch

Work

Lead

MIG Polarity

Lead

Remote

Control

Socket

Negative

Welding

Terminal (-)

Positive

Welding

Terminal (+)

Work Lead

Spool Gun

Spool

Gun

Switch

Push

Vertical

Drag/Pull

210A

20%

130A

60%

101A

100%

MIG DUTY CYCLE

200A

20%

130A

60%

101A

100%

STICK DUTY CYCLE

200A

20%

130A

60%

101A

100%

TIG DUTY CYCLE

Duty Cycle for 110V Power

Duty Cycle for 230V Power