54

LP-387 REV. 12.15.14

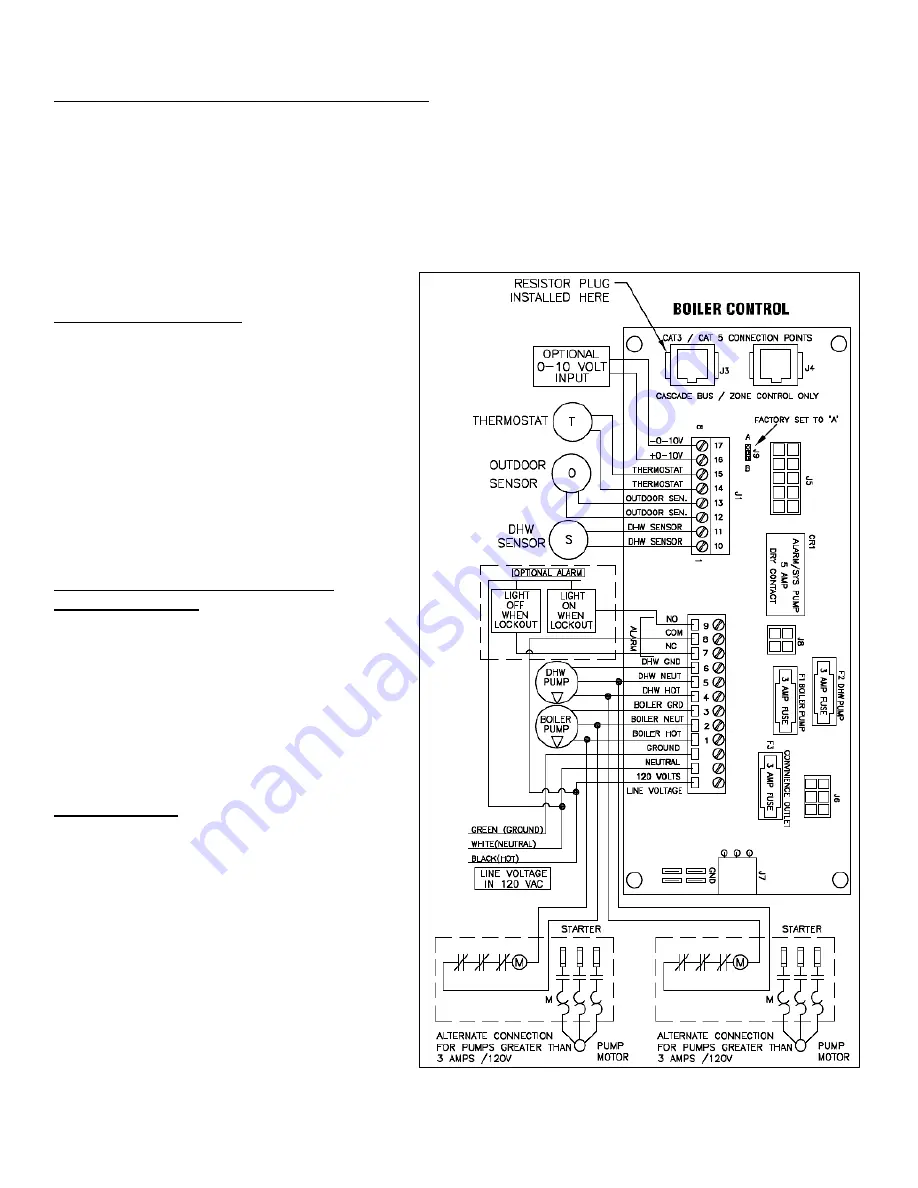

D. LINE VOLTAGE WIRING FOR STANDARD BOILER

NOTE:

A termination plug is included in the CAT 3 / CAT 5 Bus Connection Point, labeled J3 in Figure 29. DO NOT REMOVE THIS

PLUG! Doing so will affect boiler operation and void warranty.

1. Connect the incoming power wiring to the line voltage terminal strip in the electrical junction box at terminals 120V, Neutral, Ground

(shown in Figure 29).

2. A line voltage fused disconnect switch may be required, externally mounted and connected according to local codes that may apply.

3. Connect the boiler pump as shown in Figure 29 to the terminals marked 1

– (HOT), 2 – (NEUT), and 3 – (GND). The connections

shown are suitable for a maximum continuous pump draw of 3 amps at 120 volts. If the pump requires more current or voltage than the

120 volts supplied, an external motor starter or contactor

will be required.

E. ALARM CONNECTIONS

The control includes a dry contact alarm output. This is an

SPDT circuit, rated at 5 amps at 120 volts. This contact

can be used to activate an alarm light or bell or notify a

building management system if the boiler goes into a

lockout condition. The circuit between the ALARM COM

and NC terminals is closed during normal operation and

the circuit between ALARM COM and NO is open during

normal operation. The connections depicted in Figure 29

show two 120 volt lights connected to the alarm terminals.

One light will be on when the boiler is in normal mode and

the other light will be on when the boiler is in lockout

mode.

NOTE:

Isolate 120V wiring from 24V wiring to prevent any

electrical “noise”.

F. LOW VOLTAGE CONNECTIONS FOR

STANDARD BOILER

1. All low voltage cables should enter the electrical

junction box through the provided knock out holes as

shown in Figure 28.

2. Connect all low voltage field devices to the low voltage

terminal strip located in the electrical junction box.

NOTE:

When making low voltage connections, ensure no

external voltage is present in the thermostat circuits. If

external voltage is present, provide an isolated contact to

prevent damage to the control.

G. THERMOSTAT

1. Connect the room thermostat to the terminals marked

THERMOSTAT in the electrical junction box (see Figure

29). Alternately, any dry contact closure across these

terminals will cause the boiler to run. Take caution to

ensure neither of the terminals becomes connected to

ground.

2. Mount the thermostat on an inside wall as central as

possible to the area being heated, but away from drafts or

heat producing devices such as television sets that could

influence the ability of the thermostat to measure room

temperature.

3. If the thermostat is equipped with an anticipator and it is

connected directly to the boiler, the anticipator should be

set at 0.1 amps. If the thermostat is connected to other

device(s), the anticipator should be set to match the power

requirements of the device(s). See the instruction manual

of the connected device(s) for further information.

Figure 29

– Boiler Control

Summary of Contents for EFT-110

Page 14: ...14 LP 387 REV 12 15 14 SPECIFICATIONS AND DIMENSIONS Figure 2 LP 387 K ...

Page 24: ...24 LP 387 REV 12 15 14 Figure 8 Piping Symbol Legend ...

Page 58: ...58 LP 387 REV 12 15 14 Figure 32 Cascade Master and Follower Wiring ...

Page 59: ...59 LP 387 REV 12 15 14 Figure 33 Internal Connection Diagram LP 293 J ...

Page 82: ...82 LP 387 REV 12 15 14 EFT 55 80 110 PARTS BREAKDOWN Figure 36 Replacement Parts LP 387 J ...

Page 88: ...88 LP 387 REV 12 15 14 ...

Page 89: ...89 LP 387 REV 12 15 14 ...