32

It is highly recommended that you carefully follow the glycol manufacturer’s recommended concentrations,

expansion requirements, and maintenance recommendations (pH additive breakdown, inhibitor reduction, etc.)

You must carefully calculate the additional friction loss in the system as well as the reduction in heat transfer

coefficients.

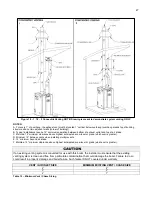

M. ZONING WITH ZONE VALVES

1. When zoning with zone valves, connect the boiler to the system as shown in Piping Details, Part 4, Section G.

The primary/secondary piping shown ensures the boiler loop will have sufficient flow. It also avoids applying the

high head of the boiler circulator to the zone valves.

2. Connect DHW (domestic hot water) piping to indirect storage water heater as shown in Piping Details.

N. ZONING WITH CIRCULATORS

1. When using circulator zoning, connect the boiler to the system as shown in Piping Details, Part 4, Section G.

NOTE:

The boiler circulator cannot be used for a zone. It must only supply the boiler loop.

2. Install a separate circulator for each zone.

3. Connect DHW (domestic hot water) piping to indirect storage water heater as shown in Piping Details.

O. MULTIPLE BOILERS

1. Connect multiple boilers as shown in Piping Details, Part 4, Section G.

2. All piping shown is reverse return to assure balanced flow throughout the connected boilers.

3. Each connected boiler must have its own circulator pump to assure adequate flow.

4. Connect DHW (domestic hot water) piping to indirect storage water heater as shown in Piping Details.

5. The system flow (secondary loop) must be greater than the boiler’s primary loop flow.

Summary of Contents for EL-110

Page 15: ...15 Figure 3 ...

Page 61: ...61 Figure 29 ...

Page 62: ...62 Figure 30 ...

Page 87: ...87 Figure 33 ...

Page 88: ...88 Figure 34 ...

Page 89: ...89 Figure 35 LP 293 A NOTE Parts listed on the following page ...

Page 94: ...94 ...

Page 95: ...95 ...

Page 96: ...96 MAINTENANCE NOTES ...