34

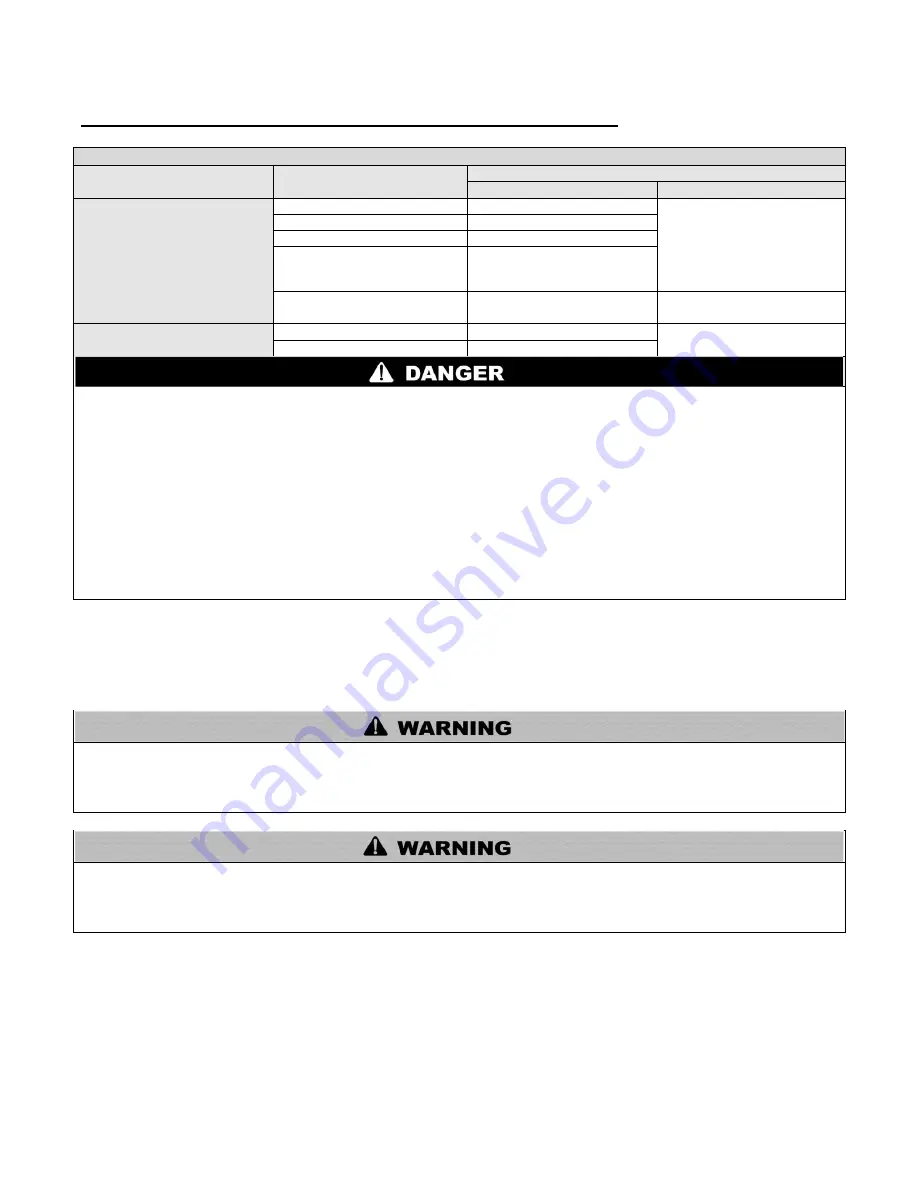

B. APPROVED MATERIALS FOR EXHAUST AND INTAKE AIR VENTS

APPROVED EXHAUST VENTING AND AIR INLET MATERIAL

Item

Material

Standards for Installation in:

United States

Canada

Exhaust vent or air inlet

pipe and fittings

PVC schedule 40/80

ANSI/ASTM D1785

PP, CPVC, and PVC

venting must be ULC-S636

Certified. IPEX is an

approved manufacturer in

Canada, supplying vent

material listed to ULC-S636.

PVC-DWV

ANSI/ASTM D2665

CPVC schedule 40/80

ANSI/ASTM F441

Polypropylene

ULCS636

Stainless Steel AL29-4C

Certified for Category IV and

direct vent appliance venting

Certified for Category IV and

direct vent appliance venting

Pipe cement/primer

PVC

ANSI/ASTM D2564

IPEX System 636 Cements

& Primers

CPVC

ANSI/ASTM F493

The air inlet and exhaust components installed with this boiler must be used for near boiler piping

BEFORE transitioning to the approved materials listed above. DO NOT REMOVE these installed

components. Doing so WILL VOID appliance warranty.

PVC/CPVC pipe and fittings of the same diameter are considered interchangeable. CPVC pipe is rated

for higher temperature applications, and is more expensive than PVC. To save installation cost, it is

recommended to use CPVC for high temperature applications ONLY.

Do NOT use Foam Core Pipe in any portion of the exhaust piping from this boiler.

DO NOT connect PVC/CPVC to PP without an approved vent connector.

When installing AL29-4C vent piping, install a PVC-to-stainless adapter at the boiler vent connection, and

at the termination when using an HTP PVC termination kit. DO NOT mix AL-29-4C piping from different

manufacturers unless using adapters specifically designed for the purpose by the manufacturer.

Failure to follow these directions will result in substantial property damage, severe personal injury, or death.

Table 8 - NOTES:

1. Air inlet piping does not require high temperature pipe material. Check applicable local codes for acceptable materials.

2. UL S636 PVC is approved for flue gas temperatures up to 149

o

F (65

o

C) and must only be used for low temperature

applications. High temperature applications requiring appliance supply water temperatures greater than 140

o

F (60

o

C) must use

ULC S636 CPVC, PP, or AL29-4C stainless steel.

DO NOT mix components from different venting systems. The vent system could fail, causing leakage of flue

products into the living space. Use only the approved pipe and fitting materials, and primer and cement

specifically designed for the material used, as listed in Table 9. Failure to do so could result in property damage,

severe personal injury, or death.

Exhaust vent adaptors are not designed as load-bearing devices, and must not be used to support exhaust vent

piping. All vent pipes must be glued, properly supported, and the exhaust must be pitched a minimum of ¼” per

foot back to the appliance to allow drainage of condensate. Failure to properly support vent piping and follow the

information in this statement could result in product damage, severe personal injury, or death.

NOTE:

The use of double-wall vent or insulated material for the combustion air inlet pipe is recommended in cold

climates to prevent the condensation of airborne moisture in the incoming combustion air.

Summary of Contents for EL-110

Page 15: ...15 Figure 3 ...

Page 61: ...61 Figure 29 ...

Page 62: ...62 Figure 30 ...

Page 87: ...87 Figure 33 ...

Page 88: ...88 Figure 34 ...

Page 89: ...89 Figure 35 LP 293 A NOTE Parts listed on the following page ...

Page 94: ...94 ...

Page 95: ...95 ...

Page 96: ...96 MAINTENANCE NOTES ...