77

Press the

▼ key once.

CASCADE SYST 118

o

F

CASCADE SET 190

o

F

This screen shows the current system temperature sensor reading on the top line and the cascade

system temperature setting on the bottom.

Press the

▼ key once.

BOILER 0 100%

BOILER 1 56%

This screen shows the current cascade power demand output on a per connected boiler basis for

boilers addressed as 0 and 1. In the screen above, boiler 0 is being commanded to fire at 100% and

boiler 1 at 56%. If this were a 2 boiler

system, the ‘CASCADE PWR’ screen above would read 156%.

Press the

▼ key once.

BOILER 2 0%

BOILER 3 0%

This screen shows the current cascade power demand output on a per connected boiler basis for

boilers addressed as 2 and 3.

Press the

▼ key once.

BOILER 4 0%

BOILER 5 0%

This screen shows the current cascade power demand output on a per connected boiler basis for

boilers addressed as 4 and 5.

Press the

▼ key once.

BOILER 6 0%

BOILER 7 0%

This screen shows the current cascade power demand output on a per connected boiler basis for

boilers addressed as 6 and 7.

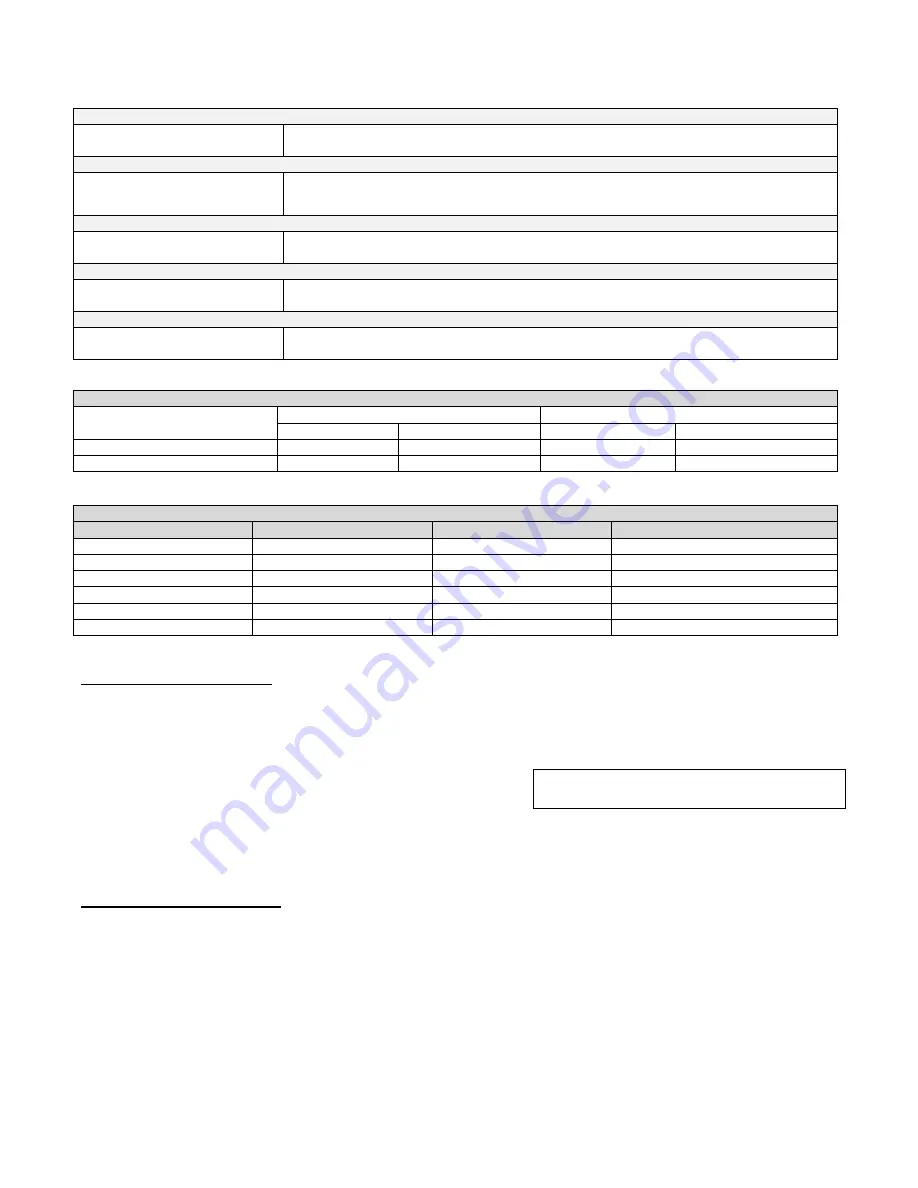

Table 23

– Cascade Menu Screens

COMBUSTION SETTINGS ON ALL MODELS

NATURAL GAS

PROPANE LP

Low

High

Low

High

CARBON MONOXIDE (CO%)

0

– 20 ppm

70

– 135 ppm

0

– 20 ppm

80

– 150 ppm

CARBON DIOXIDE (CO

2

%)

8 ½% - 9 ½%

8 ½% - 9 ½%

9 ½% - 10 ½%

9 ½% - 10 ½%

Table 24

ELITE FAN SPEEDS

MODEL

IGNITION

MIN

MAX

80

3000

1700

4600

110

3800

1700

4950

150

3800

1700

5200

220

3000

1450

4900

299

3000

1450

5000

399

3000

1600

6650

Table 25

D. TEST MODE ACCESS

To activate the test mode, be sure the appropriate pumps are running, then press the

▲ and

ENTER

keys

together for 1 second. The boiler will go through the ignition sequence. Then the user can adjust the fan speed by

pressing

▲ to increase or ▼ to decrease fan speed.

To leave service m

ode, press the ▲ and ▼ keys simultaneously.

PART 11 – TROUBLESHOOTING

A. BOILER ERROR CODE

If any of the sensors detect an abnormal condition, or an internal component fails during the operation of the

boiler, the display may show an error message and error code. This message and code may be the result of a

temporary condition, in which case the display will revert to its normal readout when the condition is corrected, or

it may be a condition that the controller has evaluated as not safe to restart the boiler. In this case, the boiler

control will be locked out, the red FAULT light will be lit, and the mes

sage “LOCKOUT” will be displayed on the

readout on the lower line.

SERVICE RUN

3400 RPM

PUMP ON

4:49P

Summary of Contents for EL-110

Page 15: ...15 Figure 3 ...

Page 61: ...61 Figure 29 ...

Page 62: ...62 Figure 30 ...

Page 87: ...87 Figure 33 ...

Page 88: ...88 Figure 34 ...

Page 89: ...89 Figure 35 LP 293 A NOTE Parts listed on the following page ...

Page 94: ...94 ...

Page 95: ...95 ...

Page 96: ...96 MAINTENANCE NOTES ...