lp-666 Rev. 003 Rel. 001 Date 2.25.20

72

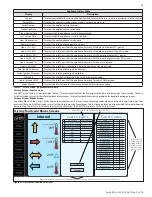

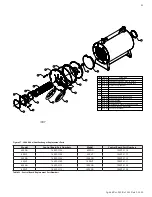

Outdoor Sensor (7250P-319)

Return Sensor (7100P-004)

Indirect Sensor

(7350P-325)

Supply Sensor (7700P-073)

Flue Temp. Sensor

(7550P-147)

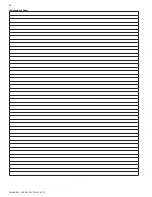

Temperature (

o

F) Resistance (ohms)

Temperature (

o

F)

Resistance (ohms)

-22

171800

32

32624

-13

129800

41

25381

-4

98930

50

19897

5

76020

59

15711

14

58880

68

12493

23

45950

77

10000

32

36130

86

8056

41

28600

95

6530

50

22800

104

5324

59

18300

113

4365

68

14770

122

3599

77

12000

131

2982

86

9804

140

2483

95

8054

149

2079

104

6652

158

1748

113

5522

167

1476

176

1252

185

1066

194

912

203

782

212

674

Table 31 - Sensor Temperature Resistance

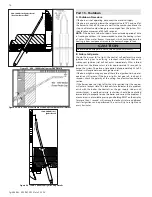

Part 14 - Maintenance

A. Procedures

Periodic maintenance should be performed once a year by a qualified

service technician to assure that all the equipment is operating safely

and efficiently. The owner should make necessary arrangements with

a qualified heating contractor for periodic maintenance of the boiler.

The installer must also inform the owner that a lack of proper care and

maintenance of the boiler may result in a hazardous condition.

BEFORE EACH HEATING SEASON a trained and qualified service

technician should perform the inspections as per the boiler

inspection and maintenance schedule in this manual. Failure to do

so could result in death or serious injury.

The combustion chamber insulation in this product contains ceramic

fiber material. Ceramic fibers can be converted to cristobalite in

very high temperature applications. The International Agency for

Research on Cancer (IARC) has concluded, “Crystalline silica inhaled

in the form of quartz or cristobalite from occupational sources is

carcinogenic to humans (Group 1).”

• Avoid breathing dust and contact with skin and eyes.

• Use a NIOSH certified dust respirator (N95). This type of

respirator is based on the OSHA requirements for cristobalite at

the time this document was written. Other types of respirators

may be needed depending on job site conditions. Current

NIOSH recommendations can be found on the NIOSH website:

http://www.cdc.gov/niosh/homepage.html. NIOSH approved

respirators, manufacturers, and phone numbers are also listed on

this website.

• Wear long-sleeved, loose fitting clothing, gloves, and eye

protection.

• Apply enough water to the combustion chamber lining to prevent

dust.

• Wash potentially contaminated clothes separately from other

clothing. Rinse clothes washer thoroughly.

NIOSH stated First Aid.

• Eye: Irrigate immediately.

• Breathing: Fresh air.

B. Combustion Chamber Coil Cleaning Instructions

*Before beginning this procedure, have on hand the following items:

• a nylon, stainless steel, or brass brush (not steel)

• an FDA approved liquid lime scale remover in a spray bottle

• gloves and eye protection

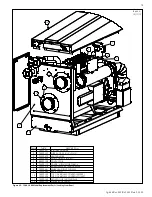

1. Shut down the boiler by using the following steps:

a. Shut the power off to the boiler at the circuit breaker.

b. Close the gas valve external to the unit. Shut down the unit,

and wait for it to be cool to the touch.

c. Open the condensate trap cleanout outside the boiler, so flow

from condensate reservoir can be observed.

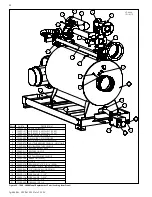

d. Disconnect electrical connections from the gas valve, spark

electrode, flame rectification probe, and combustion blower.

Make note of connections.

WARNING

!

WARNING

!

CAUTION

!

Label all wires prior to disconnecting them when servicing the

boiler. Wiring errors can cause improper and dangerous operation.

Failure to follow these instructions may result in property damage

or personal injury.

e. Disconnect the incoming flex line to the gas valve.

f.

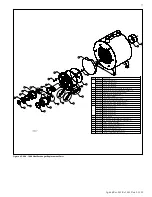

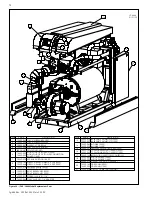

i. For 400 - 1000 Models: Remove the six (6) 10MM bolts from

the burner plate assembly.

ii. For 1500 - 2000 Models: Remove the eight (8) 10MM bolts

from the burner plate assembly with a 12mm Allen key.