68

LP-171 Rev. 3.3.15

heater. Installer must also inform the owner that the lack of proper care and maintenance of the heater may result in a hazardous

condition. The installer should discuss the contents of the User's Information Manual with the owner.

BEFORE EACH HEATING SEASON a trained and qualified service technician should perform the inspections and maintenance

procedures as identified in this manual. In addition, the maintenance and care of the heater outlined in this manual must be performed

to assure maximum efficiency and reliability. Failure to do so could result in substantial property damage, serious personal injury, or

death.

The combustion chamber insulation in this product contains ceramic fiber material. Ceramic fibers can be converted to cristobalite in

very high temperature applications. The International Agency for Research on Cancer (IARC) has concluded, “Crystalline silica inhaled

in the form of qu

artz or cristobalite from occupational sources is carcinogenic to humans (Group 1).”

Avoid breathing dust and contact with skin and eyes.

Use NIOSH certified dust respirator (N95). This type of respirator is based on the OSHA requirements for cristobalite at the

time this document was written. Other types of respirators may be needed depending on job site conditions. Current NIOSH

recommendations can be found on the NIOSH website at http://www.cdc.gov/niosh/homepage.html. NIOSH approved

respirators, manufacturers, and phone numbers are also listed on this website.

Wear long-sleeved, loose fitting clothing, gloves, and eye protection.

Apply enough water to the combustion chamber to prevent dust.

Wash potentially contaminated clothes separately from other clothing. Rinse clothes washer thoroughly.

NIOSH stated First Aid.

Eye: Irrigate immediately.

Breathing: Fresh Air.

B. MAINTENANCE SCHEDULE FOR THE SERVICE TECHNICIAN

The following maintenance should be performed annually by a qualified service technician:

General

Attend to any reported problems.

Inspect the interior of the heater jacket area; clean and vacuum if necessary.

Clean the condensate trap and fill with fresh water.

Check for water, gas, flue and condensate leaks.

Verify flue vent piping and air inlet piping are in good condition, properly supported, and tightly sealed.

Check heater water pressure, piping and expansion tank.

Check control settings.

Check ignition electrode. Sand off any white oxide. Clean and reposition.

Check ignition and ground wiring.

Check all control wiring and connections.

Check burner flame pattern (stable and uniform).

Additional Items if Combustion or Performance is Poor

Clean heat exchanger and flue ways.

Remove burner assembly and clean burner head using compressed air only.

Once the maintenance items are completed, review service with the owner.

C. COMBUSTION CHAMBER COIL CLEANING INSTRUCTIONS

*Before beginning this procedure, you must have on hand the following items:

A nylon, stainless or brass brush (not steel)

A liquid calcium and lime deposit remover

Gloves, eye protection

1. Shut down the heater by using the following steps:

a. Close the gas valve, shut down the unit and wait for the unit to be cool to the touch.

b. Disconnect the condensate hose from the

outside

connection,

(not from the heater side)

, so flow can be observed.

c. Disconnect connections from the gas valve, spark electrode and flame rectification probe and combustion blower.

d. Remove the (4) s

crews on the aluminum ½” NPT connector on the gas valve.

e. Disconnect the wiring connected to the combustion blower motor.

f. Remove the (4) 10MM nuts from the burner plate assembly to access the coils.

g. Pull the entire burner plate assembly with blower still attached towards you, while removing or pushing aside any wiring to

allow the removal of the assembly.

Summary of Contents for MC120

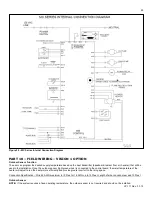

Page 21: ...21 LP 171 Rev 3 3 15 M PIPING DETAILS Figure 5 ...

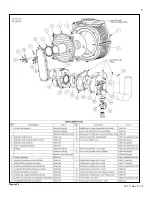

Page 53: ...53 LP 171 Rev 3 3 15 Figure 30 ...

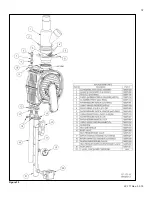

Page 71: ...71 LP 171 Rev 3 3 15 Figure 34 ...

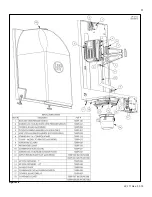

Page 72: ...72 LP 171 Rev 3 3 15 Figure 35 ...

Page 73: ...73 LP 171 Rev 3 3 15 Figure 36 ...

Page 76: ...76 LP 171 Rev 3 3 15 ...

Page 77: ...77 LP 171 Rev 3 3 15 ...