36

LP- 428 REV. 9.2.14

2. ROOM AIR, INDOOR COMBUSTION, AND VENTILATION AIR

INSTALLATION REQUIREMENTS

When using an indoor combustion air installation, the mechanical room MUST be

provided with properly sized openings, and/or be of sufficient volume to assure

adequate combustion air and proper ventilation for all gas fired appliances in the

mechanical room to assure adequate combustion air and proper ventilation. The

requirements shown here are for the boiler only. Additional gas fired appliances in

the mechanical room will require an increase in the net free area and/or volume to

supply adequate combustion air for all appliances. This must be done in

accordance with the National Fuel Gas Code, NFPA 54 / ANSI Z223.1.

This boiler can be vented using mechanical room air only for combustion. No

combustion air openings are needed when the boiler is installed in a space with a

volume NO LESS than 50 cubic feet per 1,000 BTU/hr of all installed gas fired

appliances and the building MUST NOT BE of “Tight Construction”.

TIGHT CONSTRUCTION:

A building with less than .4 ACH (air changes per hour).

For buildings of “Tight Construction”, provide air openings into the building from the

outside.

Indoor and outdoor combustion air may be combined by applying a ratio of

available volume to required volume times the required outdoor air opening(s)

size(s). This must be done in accordance with the National Fuel Gas Code, NFPA

54 / ANSI Z223.1.

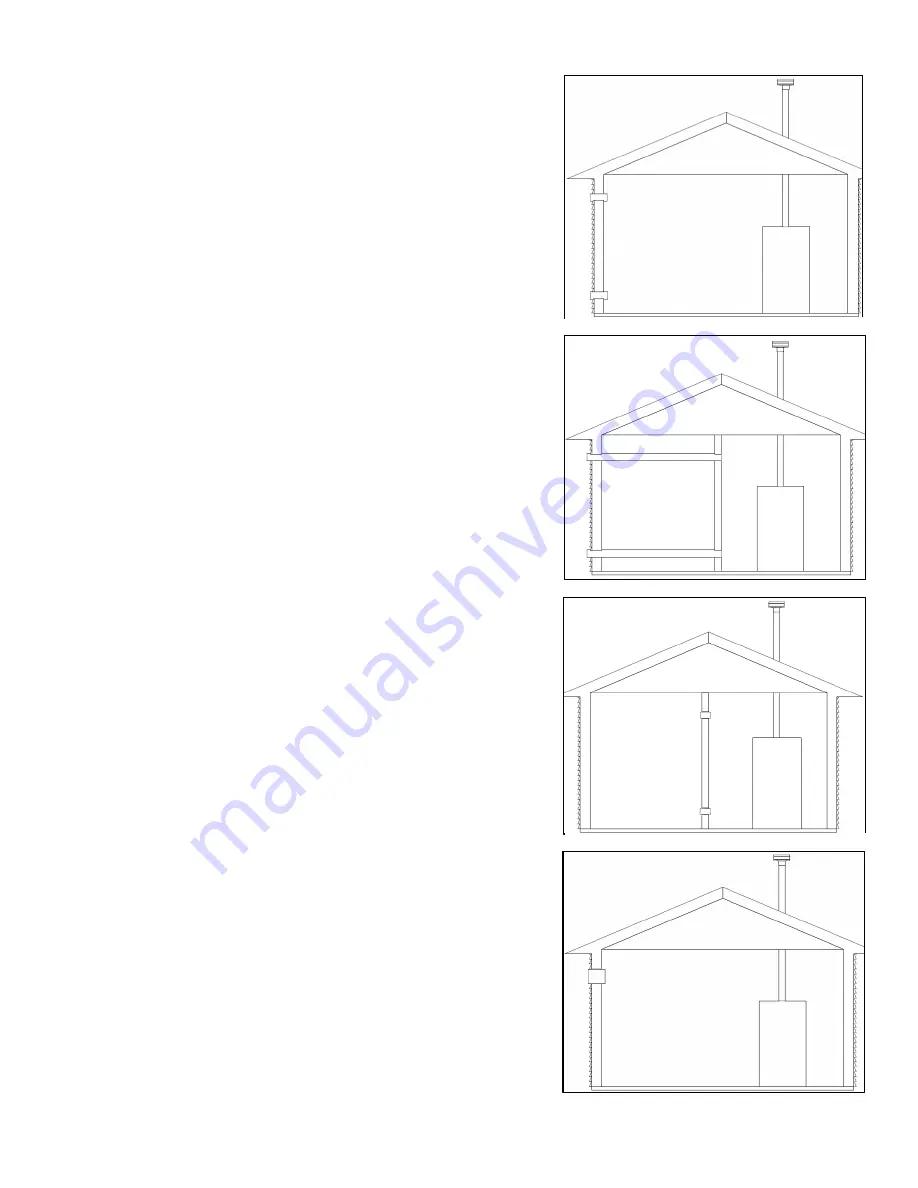

1. If air is taken directly from outside the building with no duct, provide two

permanent openings to the mechanical room each with a net free area of one

square inch per 4000 BTU/hr input. See Figure 17.

2. If combustion and ventilation air is taken from the outdoors using a duct to

deliver the air to the mechanical room, each of the two openings should be sized

based on a minimum free area of one square inch per 2000 BTU/hr input. See

Figure 18.

3. If air is taken from another interior space combined with the mechanical room:

a. Two spaces on same story: Each of the two openings specified

should have a net free area of one square inch for each 1000 BTU/hr

input, but not less than 100 square inches.

b. Two spaces on different stories: One or more openings should have a

net free area of two square inches per 1000 BTU/hr.

See Figure 19 for reference.

4. If a single combustion air opening is provided to bring combustion air in directly

from the outdoors, the opening must be sized based on a minimum free area of

one square inch per 3000 BTU/hr. This opening must be located within 12” of the

top of the enclosure. See Figure 20.

Combustion air requirements are based on the latest edition of the National Fuel

Gas Code, NFPA 54 / ANSI Z223.1, CGA Standard CAN/CSA B149.1 in Canada.

Check all local code requirements for combustion air.

All dimensions based on net free area in square inches. Metal louvers or screens

reduce the free area of a combustion air opening a minimum of approximately

25%. Check with louver manufacturers for exact net free area of louvers.

Where two openings are provided, one must be within 12” of the ceiling, and one

must be within

12”of the floor of the mechanical room. Each opening must have a

net free area as specified in Table 9

. Single openings shall commence within 12”

of the ceiling. The minimum dimension of air openings should not be less than 3”.

Figure 17

– Combustion Air From Outdoors

Figure 18

– Combustion Air Through Ductwork

Figure 19

– Combustion Air From Indoors

Figure 20

– Combustion Air From Outdoors – Single Opening

Summary of Contents for MODCON1000

Page 40: ...40 LP 428 REV 9 2 14 E GAS VALVE Figure 22 Mod Con 1000 Gas Valve ...

Page 46: ...46 LP 428 REV 9 2 14 Figure 25 Figure 26 Cascade Resistor Plug Installation Detail ...

Page 47: ...47 LP 428 REV 9 2 14 Figure 27 Mod Con Cascade Master and Follower Wiring ...

Page 48: ...48 LP 428 REV 9 2 14 Figure 28 Mod Con Internal Connection Diagram LP 428 K ...

Page 70: ...70 LP 428 REV 9 2 14 Figure 31 MOD CON 1000 External Parts Blowout ...

Page 71: ...71 LP 428 REV 9 2 14 Figure 32 MOD CON 1700 External Parts Blowout ...

Page 72: ...72 LP 428 REV 9 2 14 Figure 33 ...

Page 73: ...73 LP 428 REV 9 2 14 Figure 34 LP 445 S ...

Page 74: ...74 LP 428 REV 9 2 14 Figure 35 LP 428 V ...

Page 75: ...75 LP 428 REV 9 2 14 Figure 36 ...

Page 78: ...78 LP 428 REV 9 2 14 ...

Page 79: ...79 LP 428 REV 9 2 14 ...