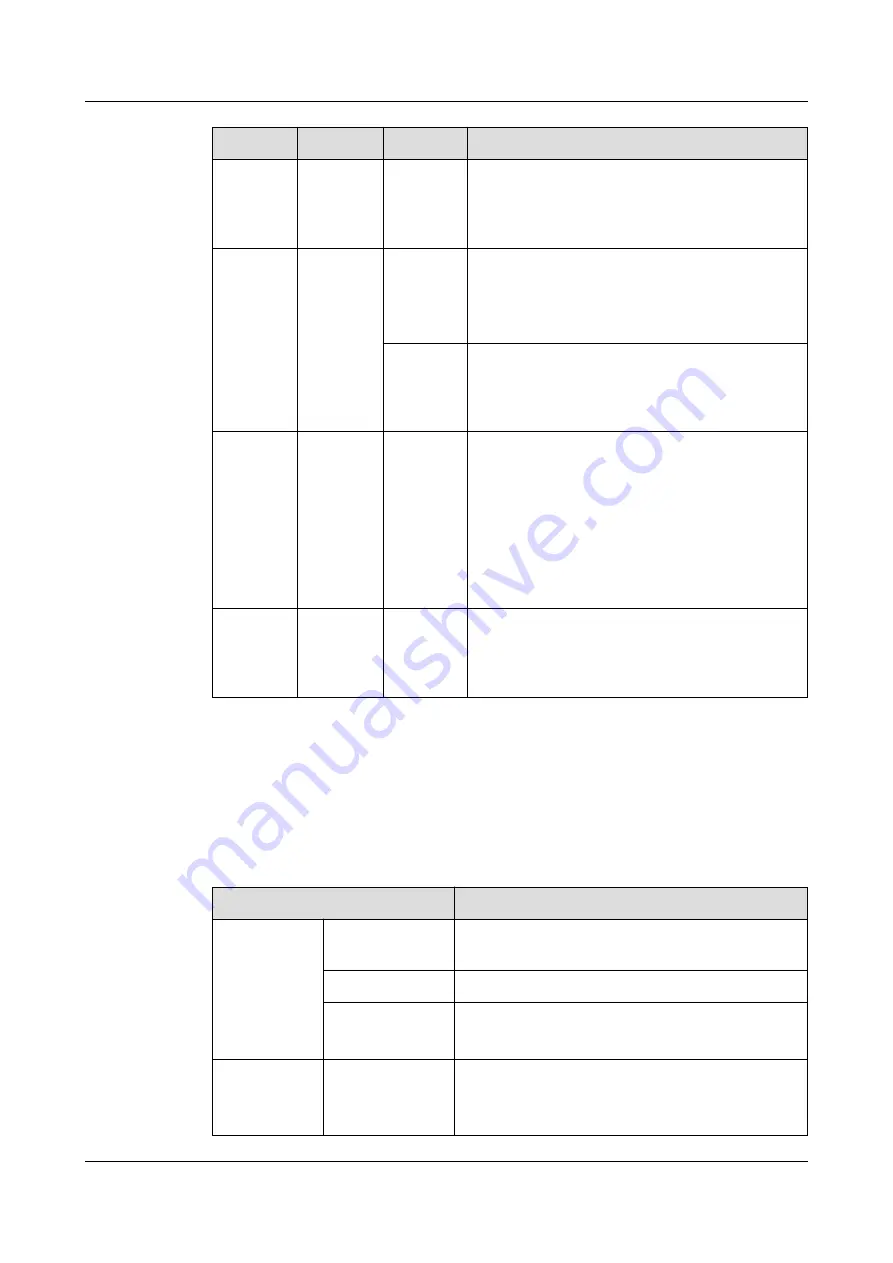

Type

Color

Status

Description

Software

startup

status

Green

Steady on

after

blinking

once

After the system is reset and starts uploading the

software, the indicator blinks green once. Until the

software is uploaded and started, the indicator

remains steady green.

Running

status

Green

Blinking

once

every 2s

(0.5 Hz)

l

The system is running properly, the Ethernet

connection is normal, and STAs are associated

with the AP.

l

The system enters the Uboot CLI.

Blinking

once

every 5s

(0.2 Hz)

The system is running properly, the Ethernet

connection is normal, and no STA is associated

with the AP. The system is in low power

consumption state.

Alarm

Green

Blinking

once

every

0.25s (4

Hz)

l

The software is being upgraded.

l

After the software is loaded and started, the AP

requests to go online if it works in Fit AP or

cloud-based management mode. The indicator

remains in this state before the AP successfully

goes online.

l

The AP works in Fit AP or cloud-based

management mode and fails to go online.

Fault

Red

Steady on

A fault that affects services has occurred, such as a

DRAM detection failure or system software

loading failure. The fault cannot be automatically

rectified and must be rectified manually.

1.3 Basic Specifications

provides basic specifications of the AP4050DN-E.

Table 1-3

Basic specifications

Item

Description

Physical

specifications

Dimensions (H x

W x D)

53 mm x 220 mm x 220 mm

Weight

0.84 kg

System memory

l

256 MB DDR3L

l

64 MB NOR FLASH

Power

specifications

Power input

l

DC: 12 V ± 10%

l

PoE power supply: in compliance with IEEE

802.3at

AP4050DN-E

Hardware Installation and Maintenance Guide

1 Product Overview

Issue 05 (2018-02-02)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

4