FusionModule1000A40 IT Solution

Maintenance Guide (2016.05, AI Version)

5 Components Replacement

Issue 04 (2018-01-05)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

95

A spare RH2288 server of the same model is available and functional.

Impact on the System

The operation of the RH2288 system or devices may be interrupted.

Preparations

Tools: Phillips screwdriver, small-sized flat-head screwdriver, ESD gloves, marker

Materials: spare RH2288 server

Documents: documents delivered with the RH2288 server, management system initial

configuration table, monitoring device layout diagram

Skill requirement: weak-current engineer

For the diagrams and tables, see the initial configuration parameter manual for the solution in use.

Procedure

Step 1

Press and hold the power switch on the front panel of the RH2288 server for about 5s to

power off the server, and disconnect the power plug.

Step 2

Mark cables and ports on the RH2288 server using a marker.

Step 3

Remove all cables connected to the RH2288 server.

Step 4

Remove the faulty RH2288 server using a Phillips screwdriver and install a new RH2288

server.

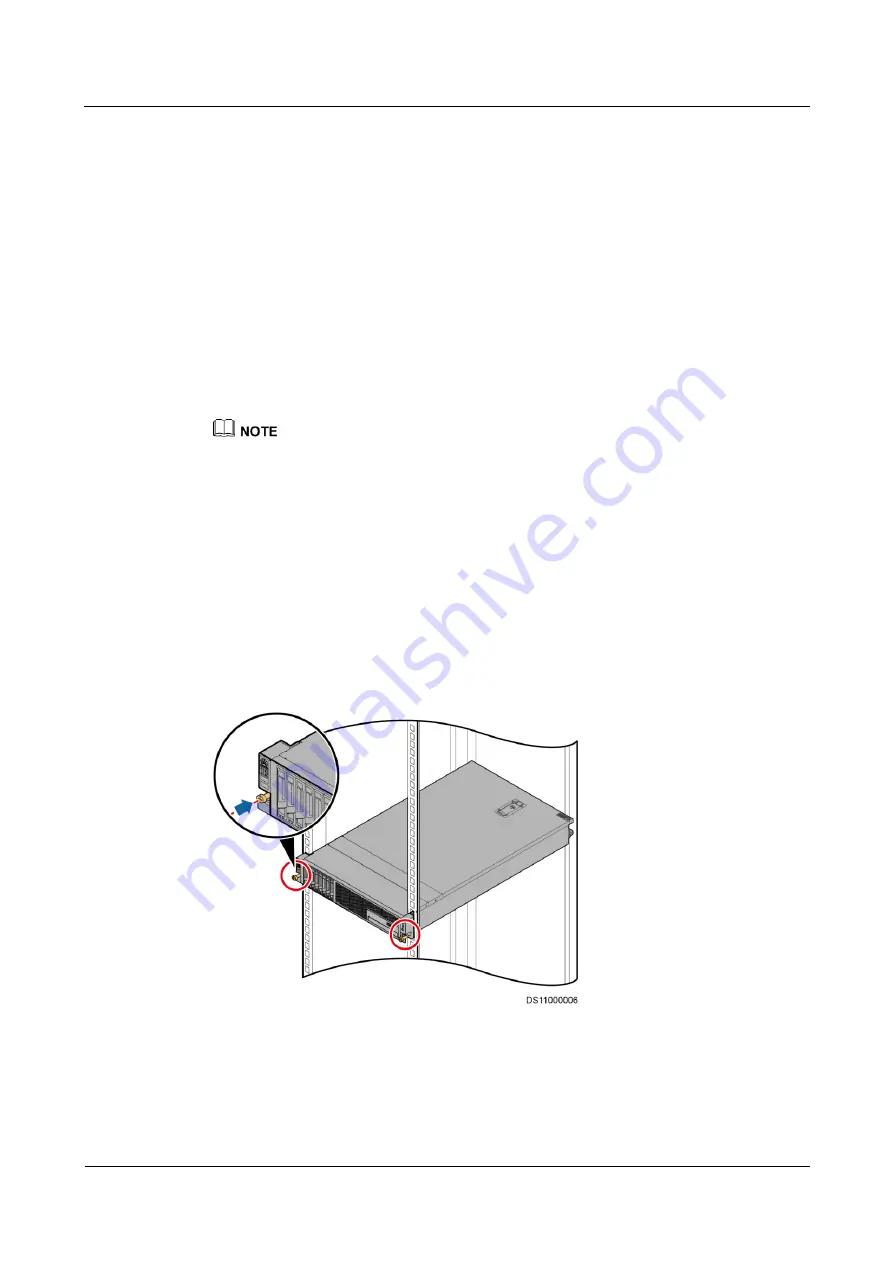

Figure 5-21

Installing the RH2288 server

Step 5

Reconnect the cables and the power plug.

Step 6

Press and hold the power switch on the front panel of the RH2288 server for about 5s to

power on the server, and check that the RH2288 server is working properly.