iManager NetEco 6000

Device Installation and Commissioning Guide

3 Installing Devices

Issue 03 (2019-03-10)

Copyright © Huawei Technologies Co., Ltd.

35

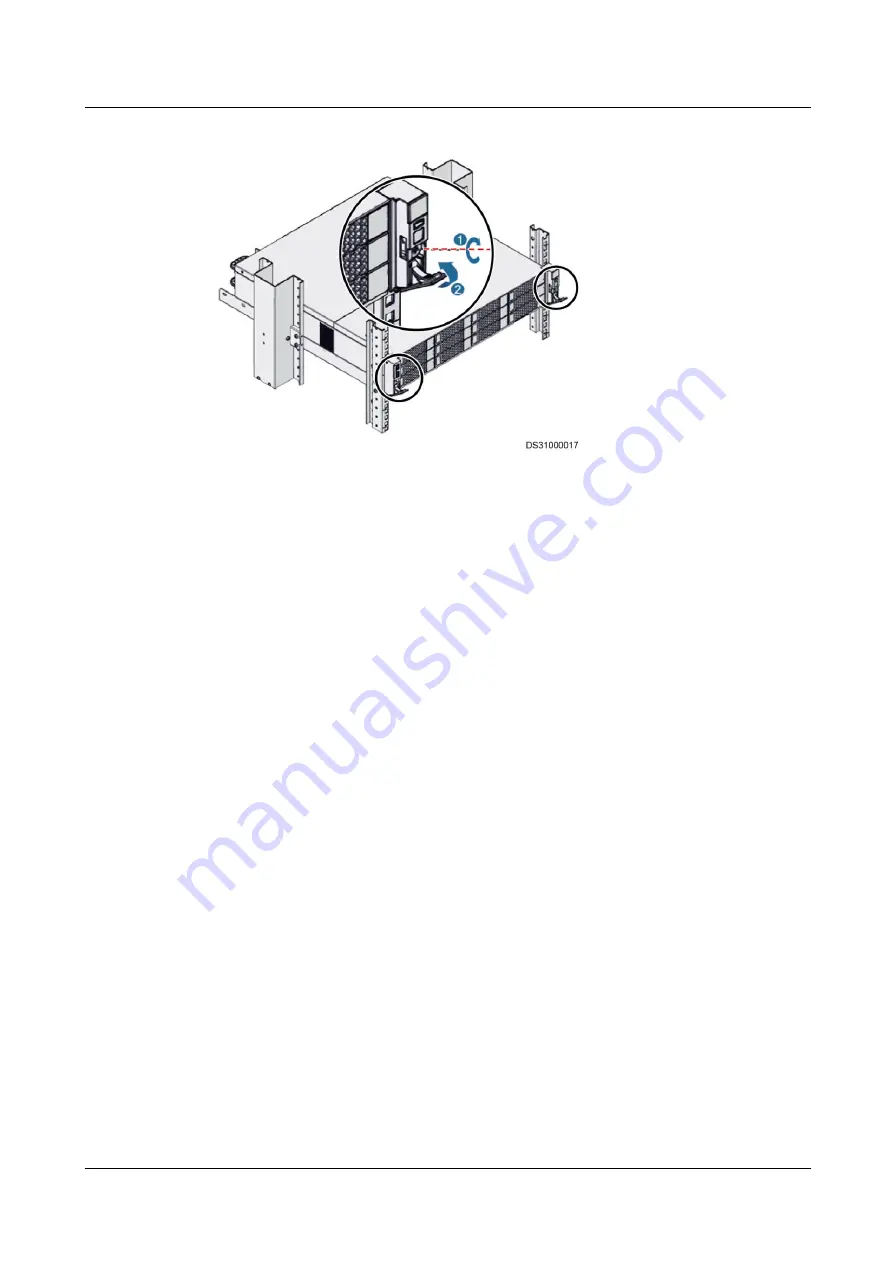

Figure 3-31

Installing the VCN500

Step 4

Connect the VCN500 power cable to the PDU2000.

----End

3.7.2 Installing an IPC6325 Camera

Prerequisites

A camera and tools for installing it have been prepared.

A network cable for connecting the camera to the switch has been prepared.

The switch has been normally powered on.

Context

This topic describes how to install and commission a camera in a room. Two persons are

required for the commissioning.

Cameras can be installed on different objects based on scenarios. This section describes

how to install a camera on the ceiling.

The camera described in this section can be installed only on a suspended ceiling if

on-ceiling installation is required.

Procedure

Step 1

(Optional) Use a Phillips screwdriver to remove the transparent cover, install the SD card.