16

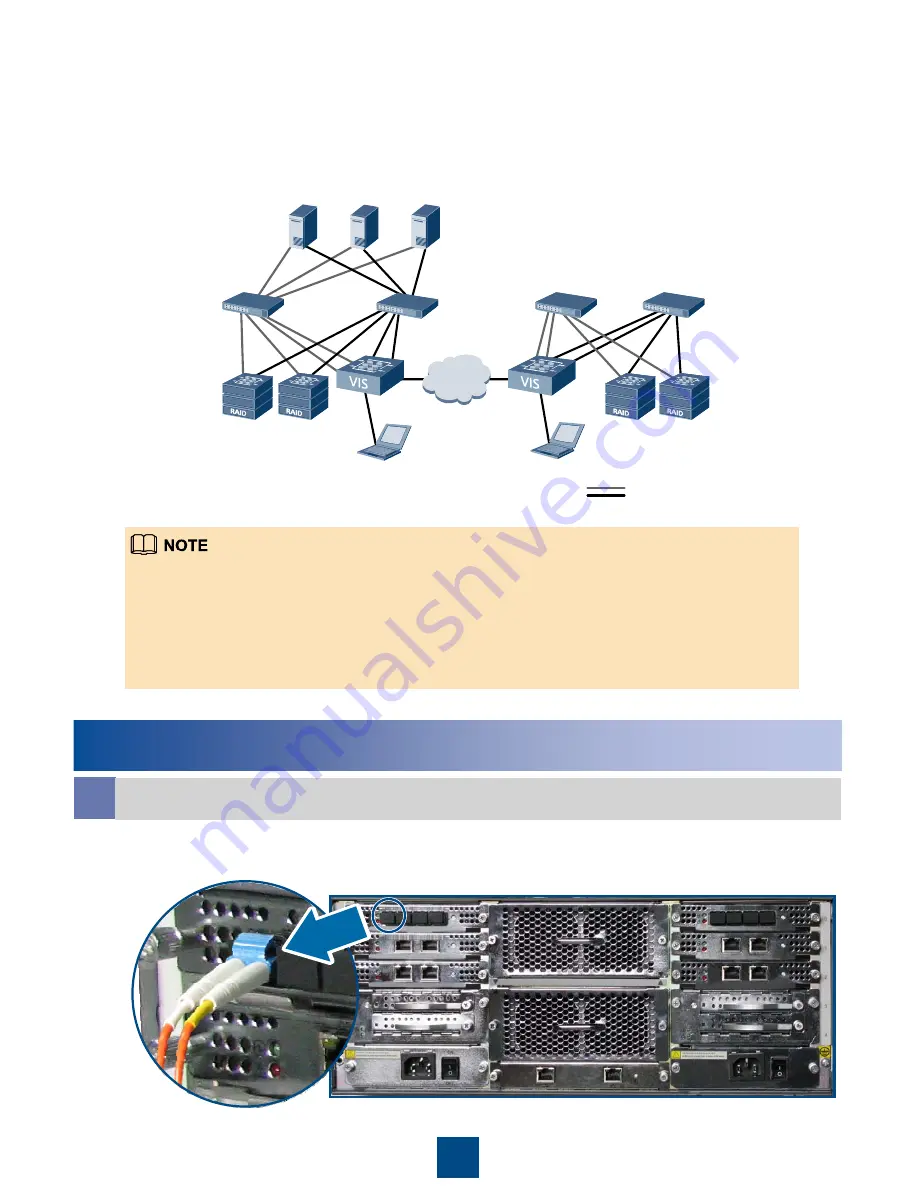

Scenario 2: Networking for Connection of the Production

Center and the Disaster Recovery Center (Only the Ethernet

Switch Is Used in the Networking of the Production Center and

the Disaster Recovery Center)

The connection of port modules on the left and right of the rear of the VIS6000 is symmetrical. The

following operation takes port modules on the left of the rear of the VIS6000 as an example. For the

connection of port modules on the right, see the following installation procedure to perform similar

operations.

The signal cables are wired on the right of the rear of the cabinet (you can lead signal cables connected

to the left port modules to the right of the cabinet by using the cable tray). When cabinets are connected,

wire the connecting cables inside the cabinet support bridges.

For the FC service ports to which FC cables are not connected, use protective caps.

Scenario 1: Connecting One End of the Optical Fiber to the FC Service Port of the

VIS6000

2 Connecting the VIS6000 to the Switch

a

Connect One End of the Cable to the Service Port of the VIS6000

Linux

AIX

Windows

VIS6000

VIS6000

WAN

Network cable

Storage arrays

Maintenance terminal

Ethernet

switch

Ethernet switch

Storage arrays

Maintenance terminal

Ethernet switch

Ethernet switch