Summary of Contents for OptiX OSN 2500

Page 1: ...HUAWEI TECHNOLOGIES CO LTD OptiX OSN 2500 Quick Installation Guide Issue 12 Date 2017 09 30 ...

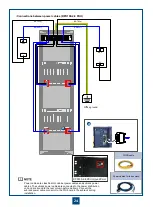

Page 19: ...16 Cable Connections c COA power interface F f cable a b a b COA power cable ...

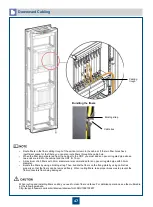

Page 36: ...33 Upward Cabling c Cable distribution plate To the alarm monitor SEI board ...

Page 37: ...34 Downward cabling d Cable distribution plate SEI board To the alarm monitor a a ...