PDU8000 Modular Precision PDC V2.0

User Manual

3 Overview

Issue 03 (2018-01-25)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

13

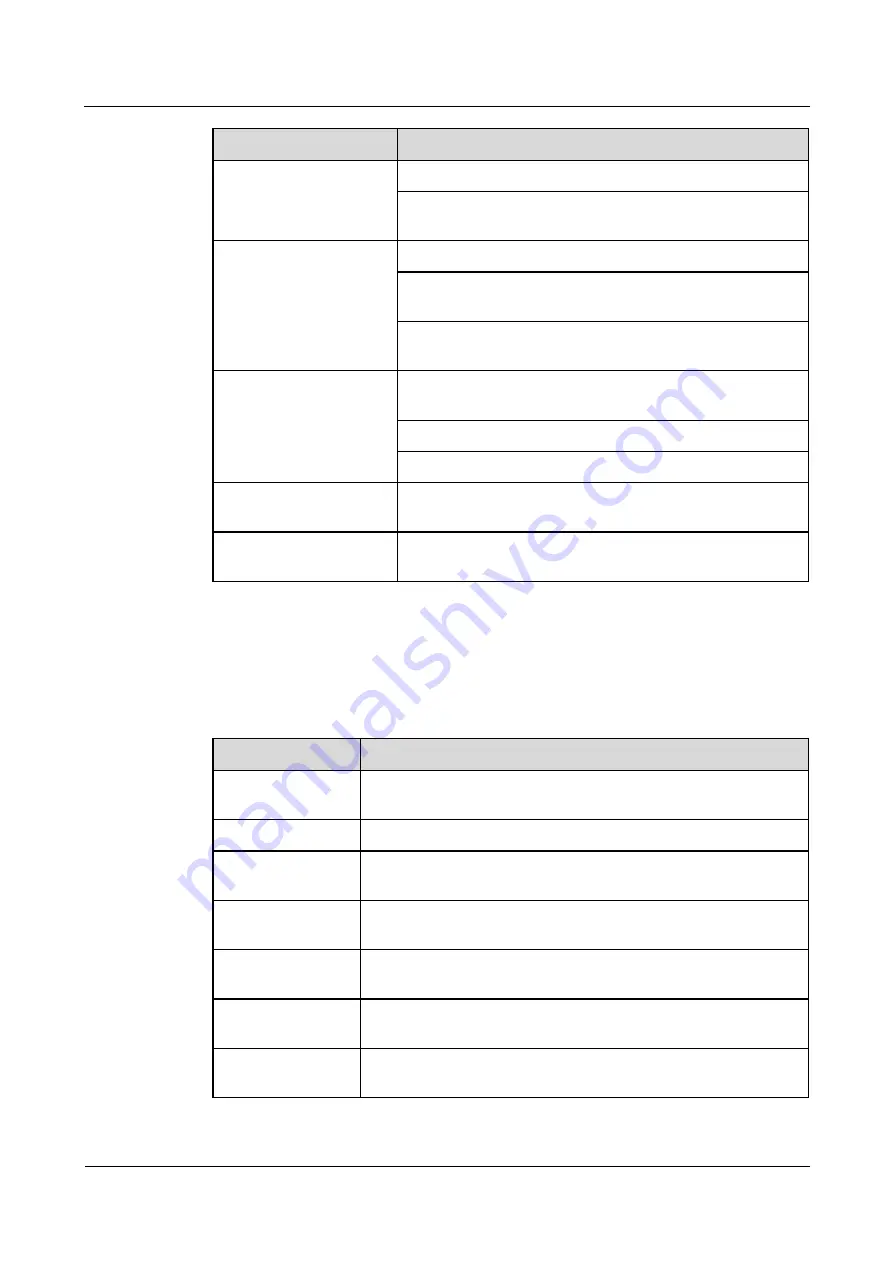

Feature

Description

Compatible with cabinets of low to high power density

(Optional) Hot-swap branch switches, making maintenance

and capacity expansion convenient

Safe and reliable

Certified by CCC, CE, and TL

Proper connection between main metal components in the

power cabinet; resistance less than 0.1 ohm

Hot-swap monitoring board; strong- and weak-current

separation

Intelligent monitoring

Strong networking capability for teleindication, telemetry,

telecontrol, and teleadjusting

Real-time monitoring and alarm reporting

(Optional) Temperature monitoring

Capacity expansion

(Optional) Capacity expansion for hot-swap circuit breakers

with power-on

Fire linkage

(Optional) The non-fire extinguishing power supply is cut off

by using 24 V DC before extinguishant is released.

3.4 Technical Specifications

Table 3-2

Technical specifications

Item

Specifications

H x W x D (mm)

2000 x 600 x 1100, 2000 x 600 x 1200, 2200 x 600 x 1200, 2500 x

600 x 1200

Weight (kg)

< 450

Rated operating

voltage (V)

208/220/380/400/415

Rated insulation

voltage (V)

500

Rated frequency

(Hz)

50/60

Rated operating

current (A)

630/400/250/160

Enclosure protection

level

IP20