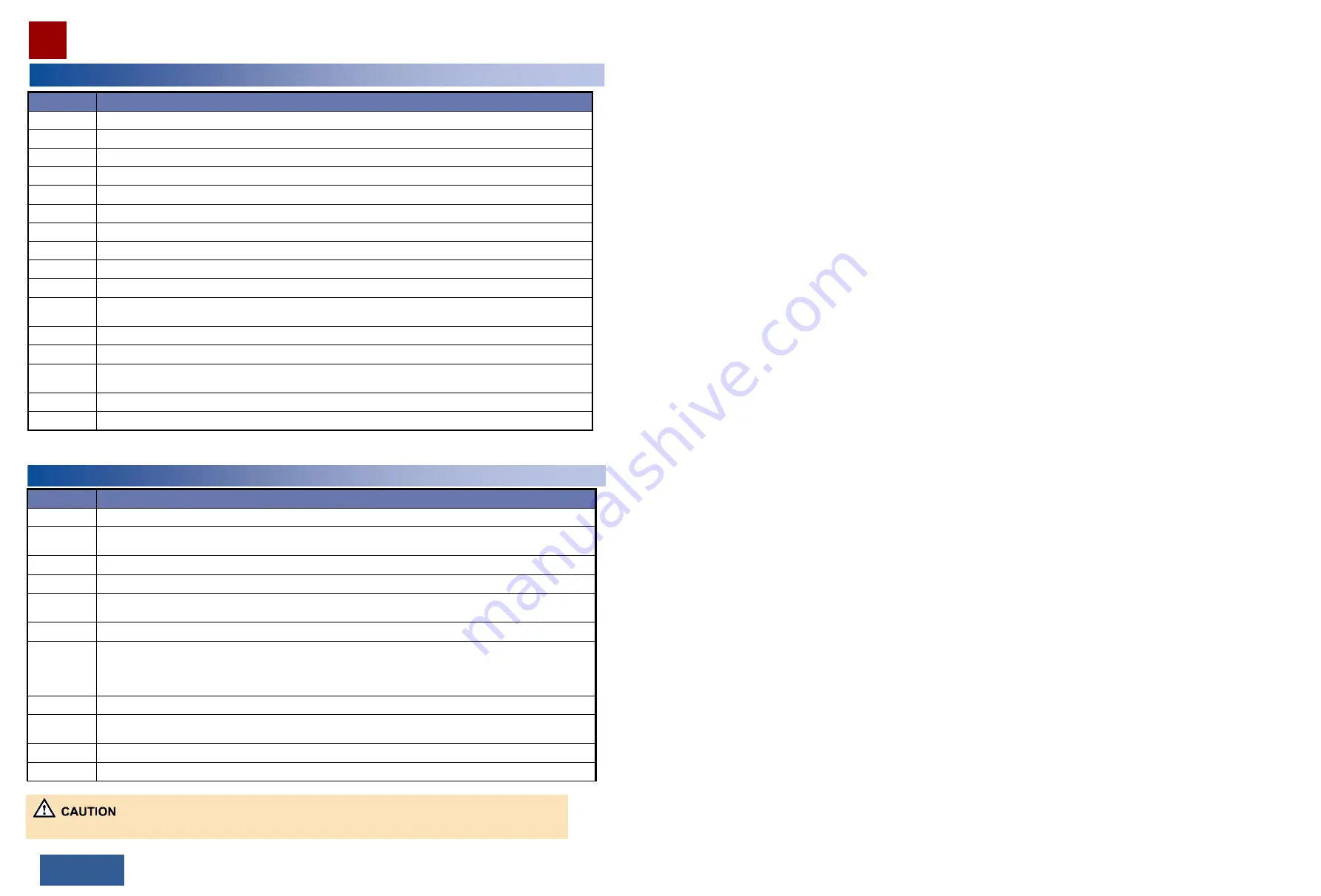

Checking the Indoor PI

No.

Check Item

1

The chassis must be installed securely in the position specified in the engineering design documents.

2

Each chassis component does not have any paint defects, damage, or stains. Re-paint or clean components that have

defects.

3

Cable routes comply with the engineering design documents and facilitate maintenance and expansion.

4

Cables are not damaged, broken, or jointed.

5

Cables are properly bound. Cable ties are installed at equal spacing and in the same direction. The excess of cable ties is

trimmed off without leaving any sharp edges.

6

Cables are routed correctly in the cabinet.

7

Cables outside the cabinet are routed as follows:

•Cables are placed tidily and are not cross-connected.

•If a cable ladder is used, the cables are bound neatly to the ladder beam. If a cable tray is 0.8 m or higher above a

cabinet, a cable ladder is available on top of the cabinet to support the cables and to ease cable stress.

8

Cable turns are smooth and have a gentle bending radius.

9

Cable labels are filled in correctly and attached securely. They are aligned and face to the same direction. Preferably, the

labels are attached 2 cm away from the connectors.

10

The power cable and ground cable are routed separately from signal cables.

11

Cable connectors are connected securely.

Checking the Cables of RTN 380e

No.

Check Item

1

All outdoor connections and ground clips are moistureproofed or waterproofed.

2

The cable connectors are assembled correctly and securely.

3

Cables are not bent or twisted and the shield layer of the power cable is intact.

4

There is a drip loop in the cable after it leaves the RTN 380e.

5

There is a drip loop in the cable before it enters the equipment room.

6

The minimum bending radius of the cables is greater than 30 cm (11.8 inches).

7

Cables are placed tidily and are not cross-connected.

8

Cables are bound to the cable ladder or tray at intervals of approximately 1 m (3.28 feet).

9

Binding tapes are cut off with an excess section reserved at the ends.

10

Attach and bind cable labels correctly. Labels must be aligned and face the same direction.

11

The excess cable is coiled into a roll with a diameter not less than 60 cm (23.62 inches). The roll is bound to the pole or

the tower.

12

The cable ground point is properly protected.

13

The power cable does not bend in the range of 0.5 m (1.64 feet) above and below the ground clip.

14

The ground cable is routed from the top downwards and the angle between the ground cable and other cables is less

than 15 degrees.

15

The ground cable of the RTN 380e is properly connected.

16

The RSSI/NMS maintenance compartment is closed and screwed.

Checking the Installation

58/59 >>

After the check is complete, power on the RTN 380e immediately to avoid moisture collecting inside the RTN 380e.