SUN2000-(30KTL-A, 33KTL, 40KTL)

User Manual

8 System Maintenance

Issue 04 (2016-06-20)

Huawei Proprietary and Confidential

Copyright © Huawei Technologies Co., Ltd.

87

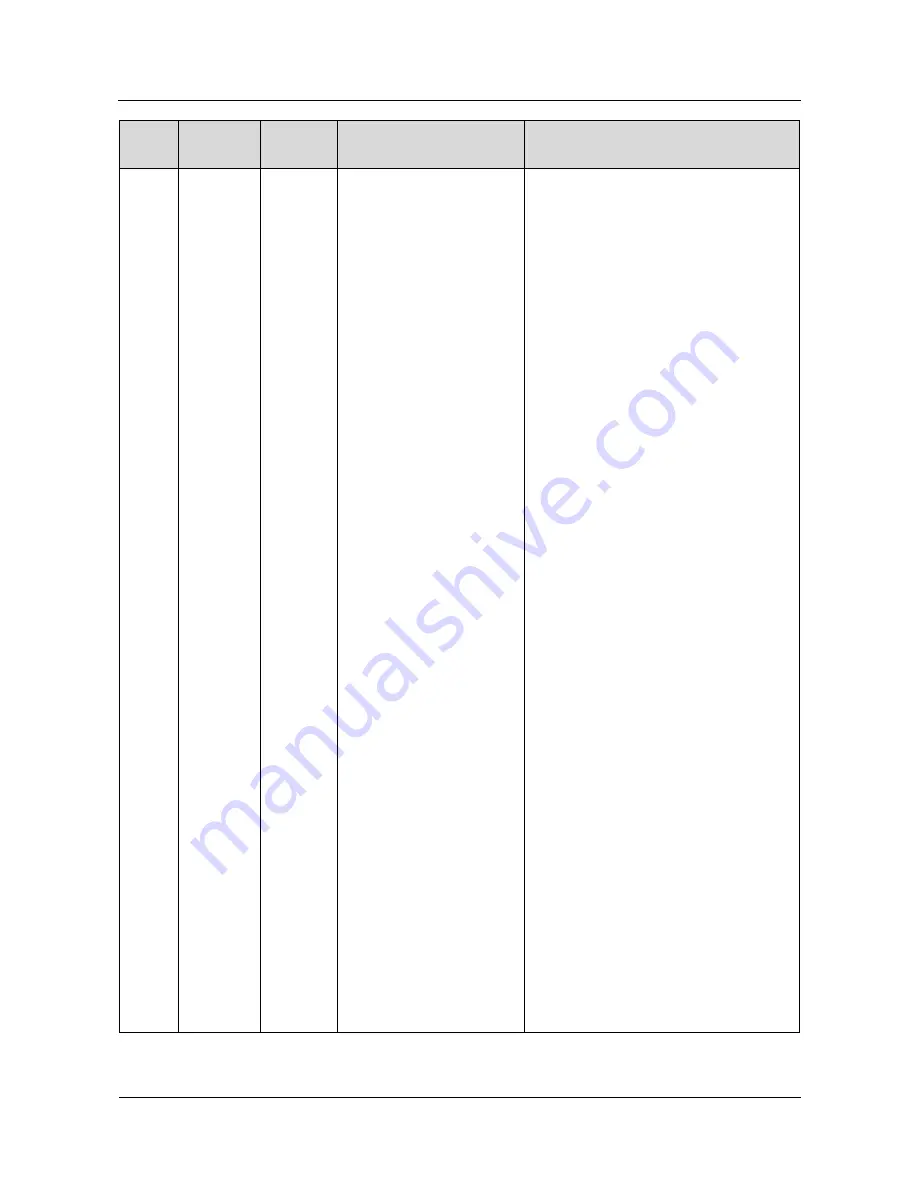

Alarm

ID

Alarm

Name

Alarm

Severity

Possible Cause

Suggestion

301

Abnormal

Grid

Voltage

Major

The power grid voltage is

beyond the acceptable

range. The possible causes

are as follows:

Cause ID = 4

The power grid voltage

is below the specified

lower threshold.

Cause ID = 16

The power grid voltage

exceeds the specified

upper threshold.

Cause ID = 19

The power grid voltage

has exceeded the

specified upper threshold

for 10 minutes.

Cause ID = 26

The power grid voltage

exceeds the specified

upper threshold.

Cause ID = 28

The three phases of the

power grid differ greatly

in voltage.

Cause ID = 29

1.

The power grid

experiences an

outage.

2.

The AC circuit is

disconnected or AC

circuit breaker is off.

Cause ID = 31–33

The impedance of the

output phase wire A/B/C

to the PE is low or

short-circuited.

Cause ID = 4

1.

If the alarm occurs accidentally, the

power grid may be abnormal

temporarily. The inverter automatically

recovers after detecting that the power

grid becomes normal.

2.

If the alarm occurs frequently, check

whether the power grid voltage is

within the acceptable range. If no,

contact the local power operator. If yes,

log in to the SUN2000 APP,

SmartLogger, or NMS to modify the

power grid overvoltage and

undervoltage protection thresholds with

the consent of the local power operator.

3.

If the fault persists for a long time,

check the AC circuit breaker and AC

output power cable.

Cause ID = 16/19/26

1.

Check whether the grid-tied voltage

exceeds the upper threshold. If yes,

contact the local power operator.

2.

If you have confirmed that the grid-tied

voltage exceeds the upper threshold and

obtained the consent of the local power

operator, modify the overvoltage and

undervoltage protection thresholds.

3.

Check whether the peak power grid

voltage exceeds the upper threshold.

Cause ID = 28

1.

If the exception is caused by an external

fault, the inverter automatically

recovers after the fault is rectified.

2.

If the alarm persists and affects the

energy yield of the power station,

contact the local power operator.

Cause ID = 29

1.

Check the AC voltage.

2.

Check that the AC power cable is

securely connected and that the circuit

breaker is ON.

Cause ID = 31–33

Check the impedance of output phase wire

A/B/C to the PE and locate the position

with lower impedance and resolve the

issue.