TP48200A-HT15D3 Telecom Power (Russia, Megafon)

User Manual

4 Maintenance

Issue 03 (2019-11-15)

Copyright © Huawei Technologies Co., Ltd.

43

4

Maintenance

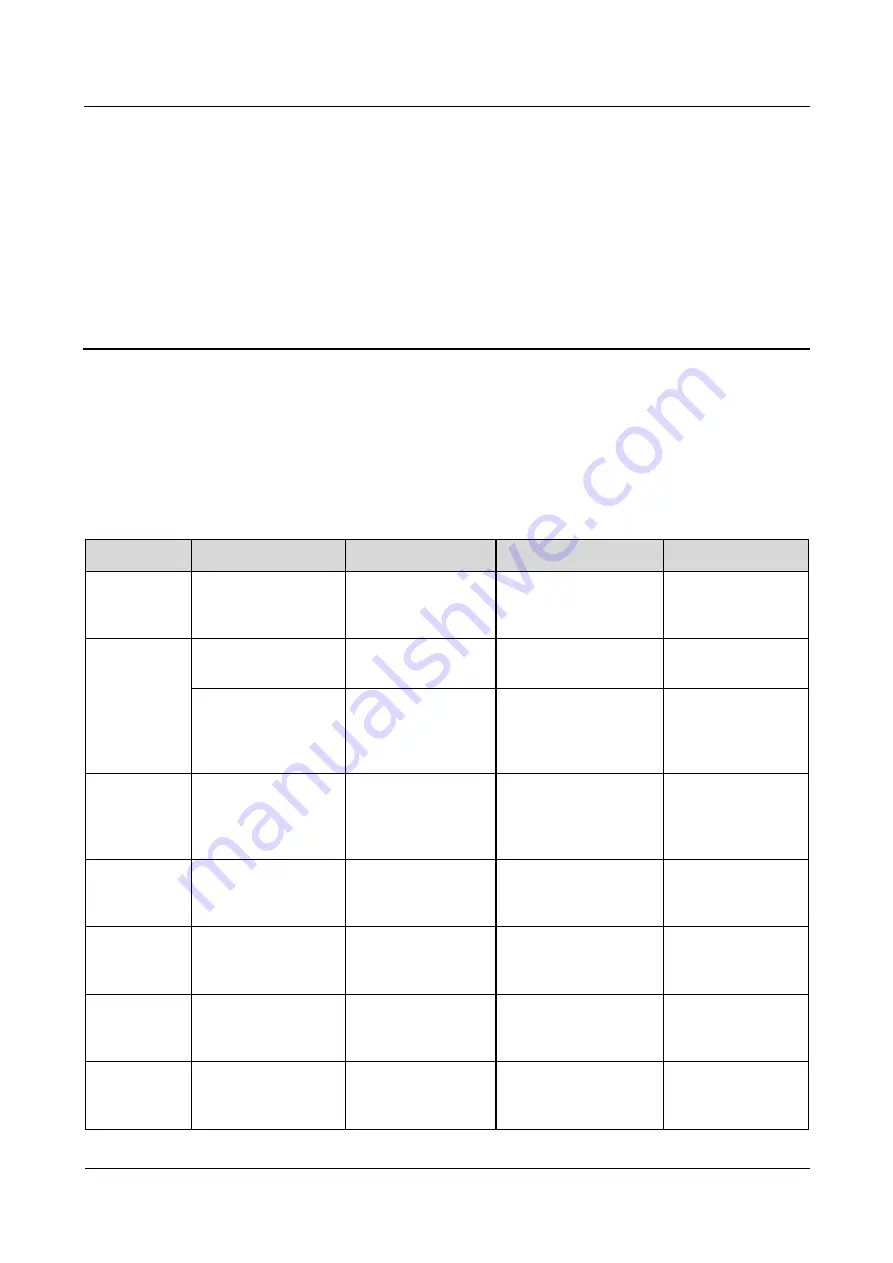

4.1 Routine Maintenance

Perform routine maintenance periodically based on site requirements. The recommended

interval is six months. If any fault occurs, rectify it in a timely manner.

Table 4-1

Routine maintenance checklist

Item

Check Whether

Check Method

Repair When

Measure

Door lock

The door lock is

damaged.

By observation or by

locking and

unlocking the door

The door lock is

damaged.

Replace the door

lock.

Fan

Dust accumulates on

the fan.

By observation

The fan is dusty.

Clean the dust.

The fan is intact, and

the rotation speed,

noise, and vibration

are in normal ranges.

By observing or

listening to the fan

The fan is damaged, the

vibration is abnormal,

or the noise is loud.

Replace the fan.

Heat

exchanger

Dust accumulates on

the heat exchanger

core.

By observation or by

checking the

temperature

The heat exchanger

core is dusty, and the

temperature is high in

the cabinet.

Clean or replace the

heat exchanger

core.

Heater

The heater works

properly.

By observation or by

checking the

temperature

The heater is damaged

and cannot effectively

heat the air.

Replace the heater.

TCUA

control board

The TCUA control

board works

properly.

By observation or by

checking the

indicator and alarms

The TCUA control

board does not work

properly.

Replace the TCUA

control board.

TEC

The TEC works

properly.

By observation or by

checking the fan and

temperature

The TEC is damaged

and cannot effectively

cool the air.

Replace the TEC.

Electricity

The output voltage is

normal.

Multimeter

The BLVD or LLVD

voltage exceeds the

threshold.

For details, see 4.2

Rectifying

Common Faults.