UPS5000-A-400 kVA

User Manual (50 kVA, PF=0.9)

3 Installation

Issue 03 (2020-01-10)

Copyright © Huawei Technologies Co., Ltd.

92

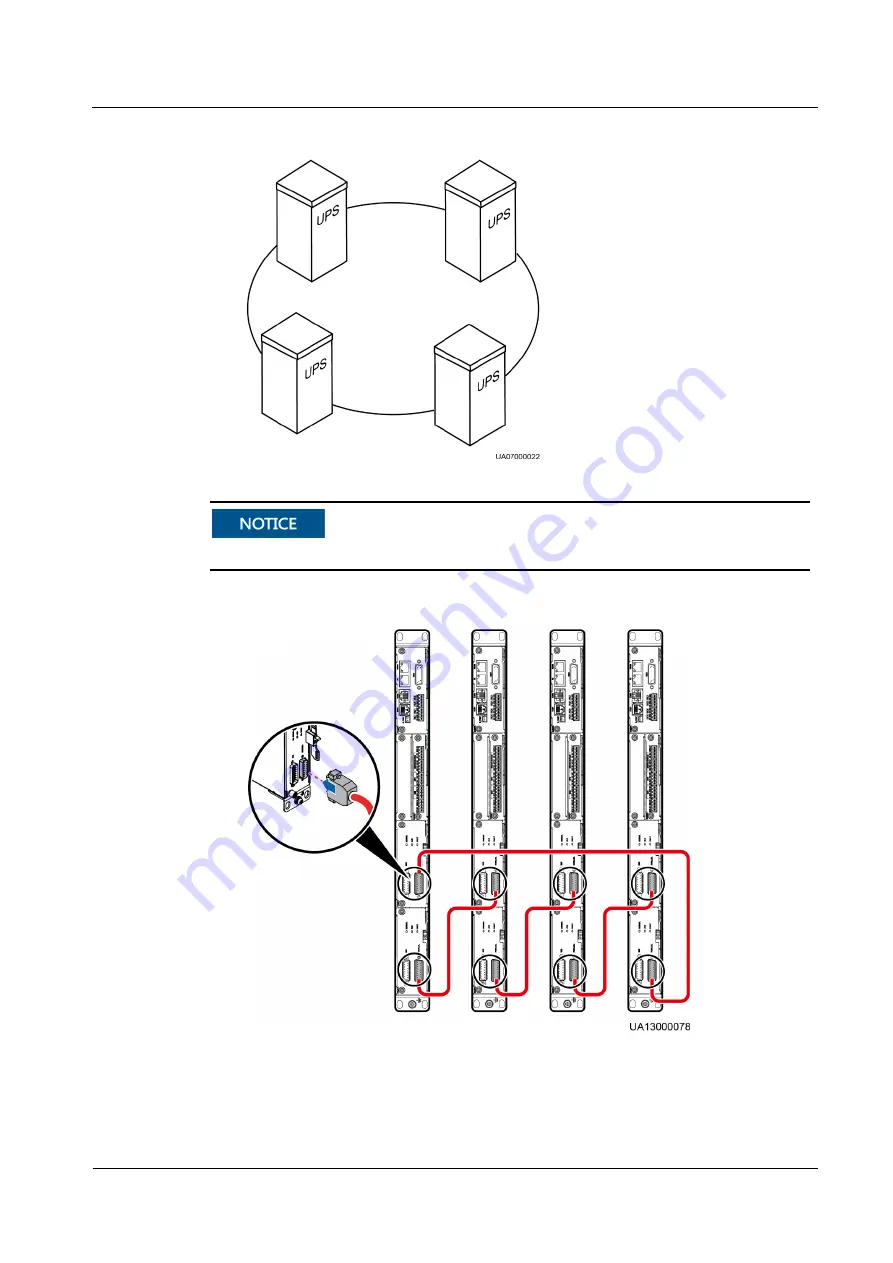

Figure 3-59

N+X parallel system topology

This figure shows the control unit only. The control unit is the substitute of a single UPS.

Figure 3-60

Signal cable connections of N+X parallel system

BSC master and slave cables are required in a dual-bus parallel system.

shows how to connect signal cables to a dual-bus system.