UPS5000-E-(25 kVA-75 kVA)-SM

User Manual (Half Height)

3 Installation

Issue 03 (2019-12-13)

Copyright © Huawei Technologies Co., Ltd.

43

The currents listed in the table are measured at a rated voltage of 380 V; if the rated

voltage is 400 V, multiply the currents by 0.95; if the rated voltage is 415 V, multiply the

currents by 0.92.

When primary loads are non-linear loads, increase the cross-sectional areas of neutral

wires to 1.5–1.7 times.

Nominal battery discharge current: the current at a voltage of 480 V when thirty-two 12

V batteries are configured.

Maximum battery discharge current: the current upon end of discharge when thirty-two

12 V batteries are configured, namely, discharge current in the case of 240 2 V battery

cells with 1.67 V/cell.

The battery cable specifications are selected based on 30 batteries by default and

compatible with application scenarios with 30–44 batteries.

To prevent short circuits, refer to

for the specifications when selecting DT

terminals.

When connecting power cables, comply with the tightening torque listed in

ensure secure connections and prevent safety risks.

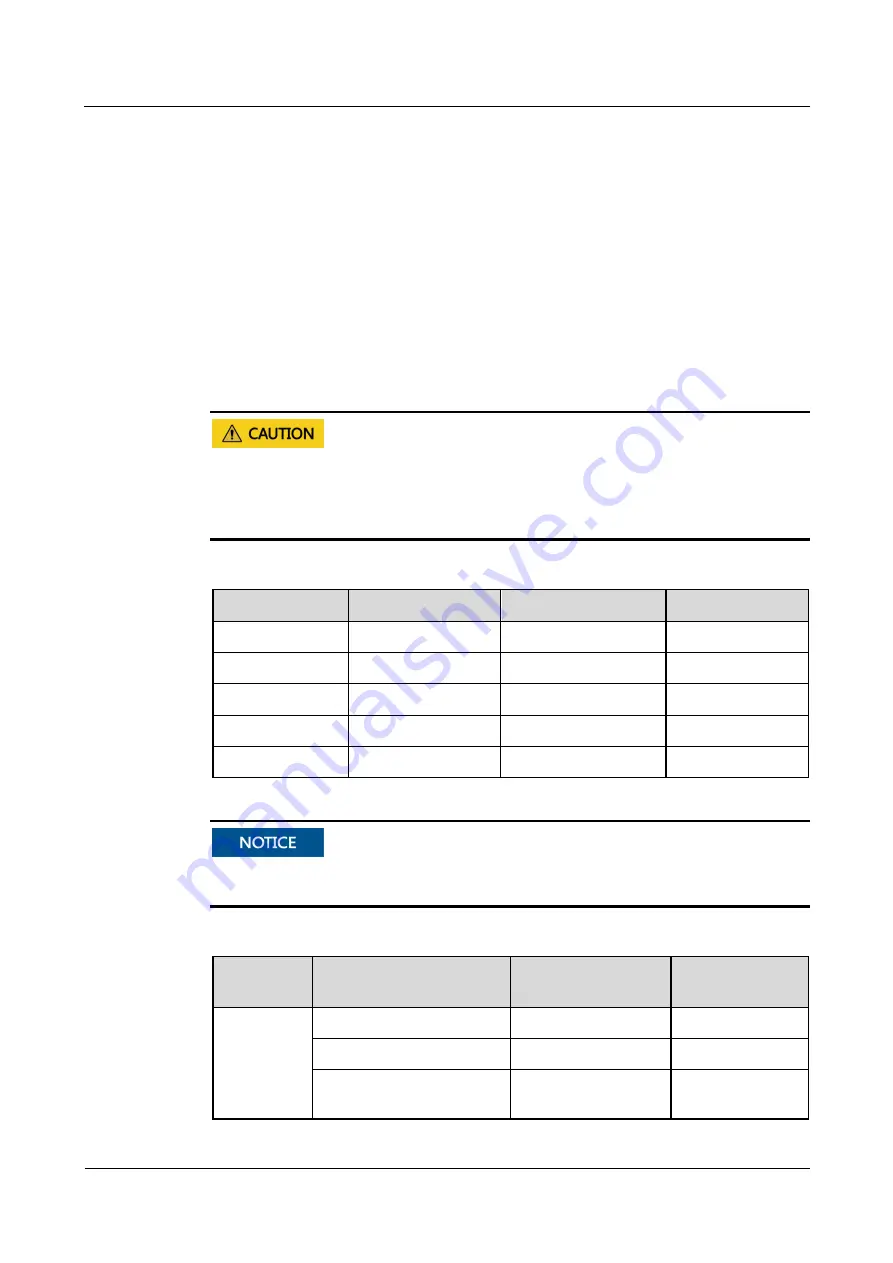

Table 3-3

Power cable DT terminal requirements

Port Description Bolt Specifications Bolt Hole Diameter

Torque

Mains input

M8 x 30

9 mm

20 N·m

Bypass input

M8 x 30

9 mm

20 N·m

Battery input

M10 x 30

11 mm

35 N·m

Output

M8 x 30

9 mm

20 N·m

PE

M8 x 20

9 mm

13 N·m

The UPS can generate large leakage currents. A circuit breaker equipped with an RCD is not

recommended.

Table 3-4

Recommended input front-end and output back-end circuit breakers

UPS

Capacity

Component

Specifications

Fixed value

25 kVA

Mains input circuit breaker

80 A/3P

80 A

Bypass input circuit breaker

63 A/3P

63 A

Output branch circuit

breaker

63 A/3P

63 A