UPS5000-E-(360 kVA-480 kVA)

User Manual (40 kVA Power Modules)

2 Overview

Issue 07 (2020-01-10)

Copyright © Huawei Technologies Co., Ltd.

27

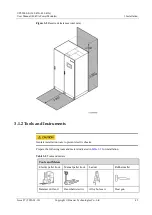

Figure 2-13

Logical connections for CAN communication

Specifications

Hot-swappable

1 U high

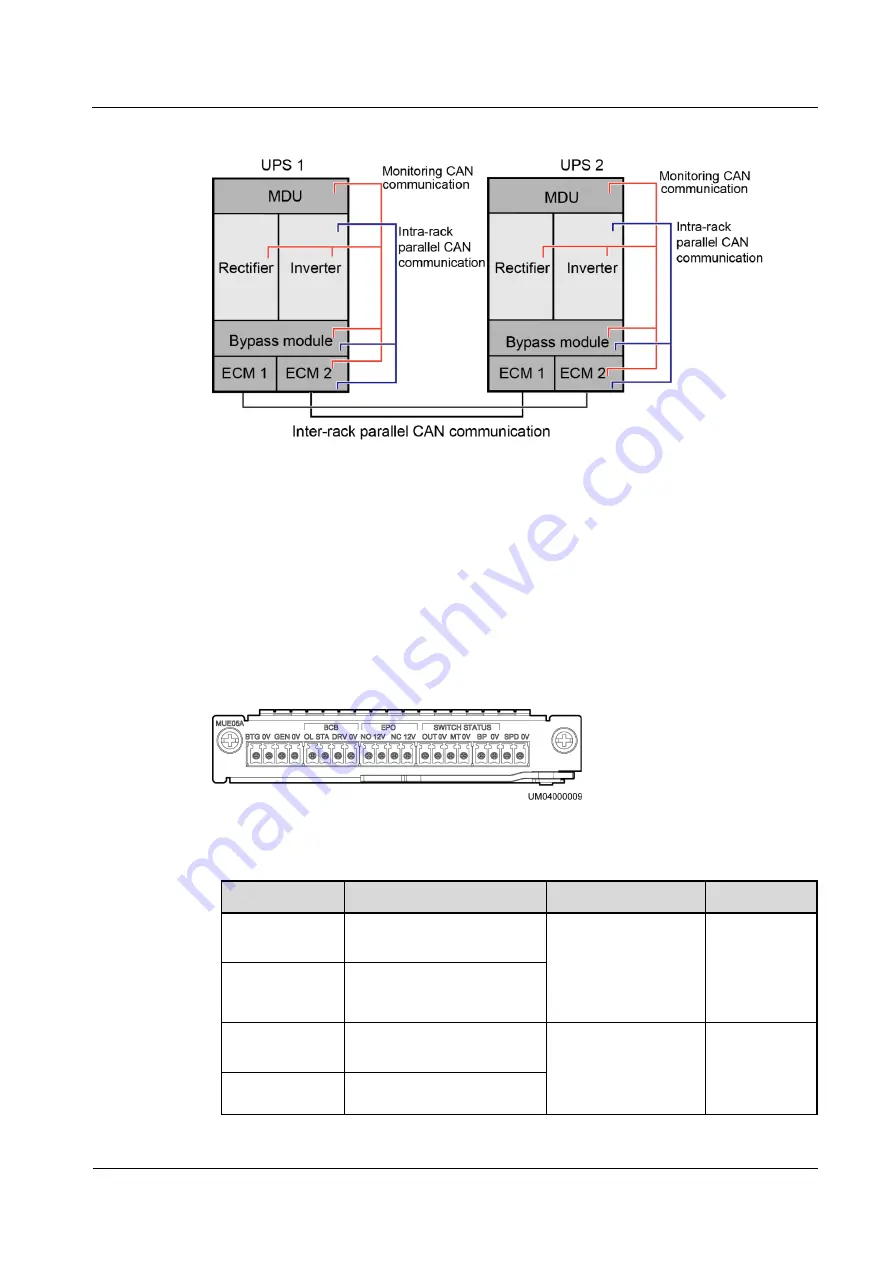

2.4.3 Dry contact card

Appearance

Figure 2-14

Dry contact card

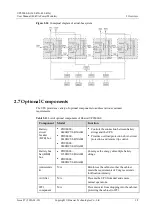

Table 2-3

Ports on the dry contact card

Silk Screen

Description

Status

Initial Status

BTG

Port for detecting battery

grounding faults

Connected: battery

grounding fault

Disconnected: no

battery grounding

fault

Disconnected

0V

Port for signal ground

GEN

Port for detecting diesel

generator (D.G.) mode

Connected: D.G.

mode

Disconnected:

non-D.G. mode

Disconnected

0V

Port for signal ground