3

Installing Cables

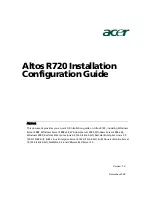

1. Connect the 3V3 connector at one end of

the BBU power cable to the

-48 V

port on the

UPEU module of the BBU, and tighten the

screws on the connector to 0.25 N·m.

2. Connect the other end of the BBU power

cable to the TP48200A cabinet.

a) Connect the cord end terminal to the

BLVD 16 A MCB port

F6

.

b) Connect the OT terminal of the BBU

power cable to the positive busbar of the

TP48200A.

Installing a Power Cable

b

Connecting Ethernet Cables or Optical Fibers to the Main Processing Board

c

a

3. Bind the cables properly using the optical fiber

binding strap based on BBU cable claw positions.

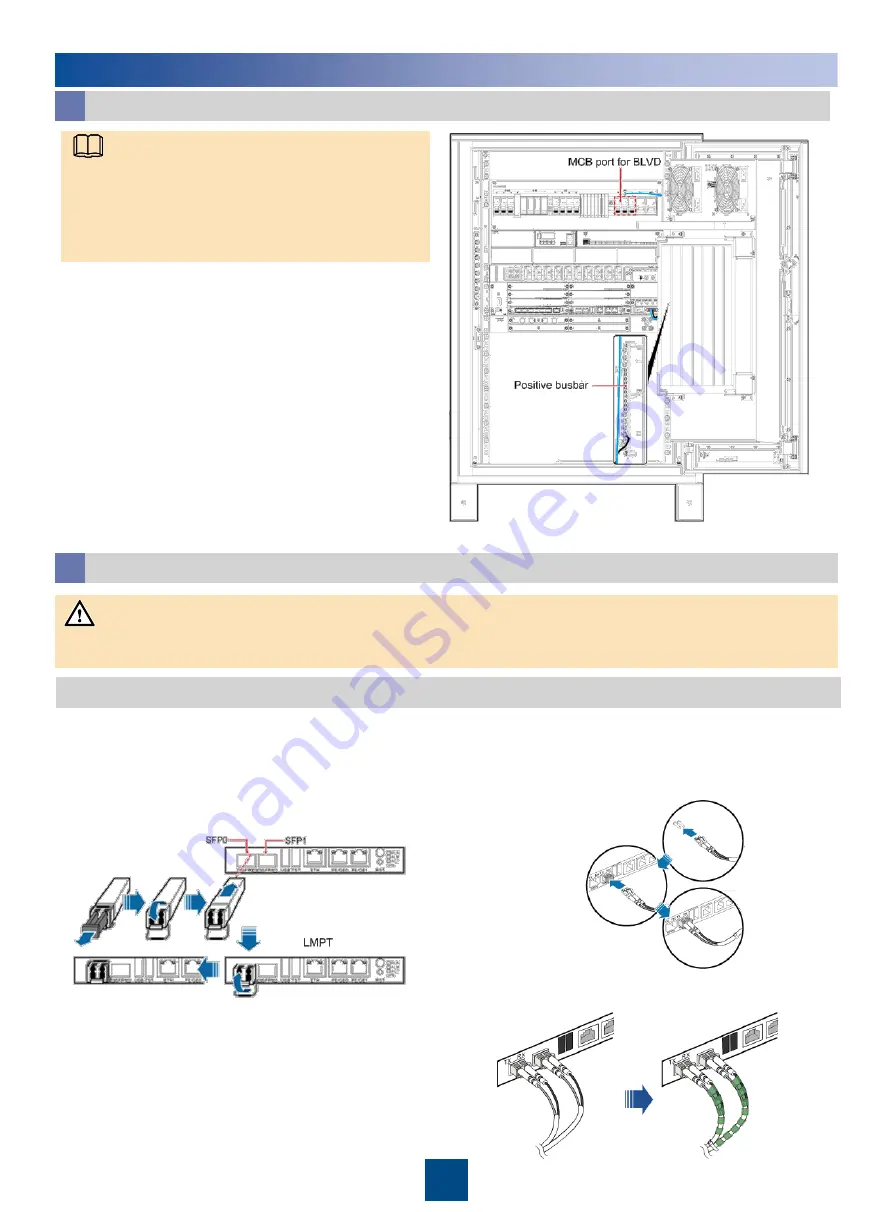

c1 Installing an FE/GE Optical Fiber

1. Lower the puller of an optical module and

insert the optical module into the

SFP0

/

SFP1

port on the LMPT, the

FE/GE1

port on the

UMPTb2, or the

XGE1

/

XGE3

port on the

UMPTe3. Then, raise the puller.

2. Remove the dustproof cap from the optical

fiber. Connect an FE/GE optical fiber to the

optical module.

4. Install the winding pipe at the end of the

optical fiber. Ensure that the winding pipe is

installed at the position between the optical fiber

connector and the first optical fiber binding point.

NOTICE

Connect Ethernet cables or optical fibers to the UMPT/LMPT based on actual requirements. Cable layout for Ethernet cables

and optical fibers is identical.

Here is the process of installing a BBU power

cable in the TP48200A cabinet. For details about

how to install a BBU power cable in other

scenarios, please see

“Installing a BBU Power

Cable” in

eNodeB Product Documentation.

NOTE