Step 6 Weld a new EEV, and install the coil for the EEV.

NO TICE

Protect the surrounding components during the welding process.

Step 7 Inject nitrogen and preserve the pressure. After checking that the EEV and system

do not leak, perform vacuumization and inject refrigerant.

Step 8 After powering on the smart cooling product, log in to the ECC800-Pro WebUI as

user admin, choose Monitoring > Cooling > NetCol5000-A1 > Controls >

Control Information, set Startup/Shutdown control to ON, and click Submit.

Step 9 Choose Controls > Control Information, set Diagnostic mode to Enter, and click

Submit.

Step 10 Choose Running Parameters > Diagnostic Mode Parameters, set Comp manual

control to 3000 rpm, and click Submit. Choose Running Info > Compressor

Information and read the air suction pressure and air exhaust pressure. Check

that the air suction/exhaust pressure of the compressor is within the proper range.

Choose Running Info > Electronic Expansion Valve Information. Check that the

EEV suction overheating degree is within the proper range.

NO TE

● The proper range of the suction pressure is 0.7–1.6 MPa, and the pressure ratio

(discharge pressure to suction pressure) is greater than 1.4.

●

lists the proper ranges of the air exhaust pressure.

● The proper range of the air suction superheat degree is 4°C to 15°C.

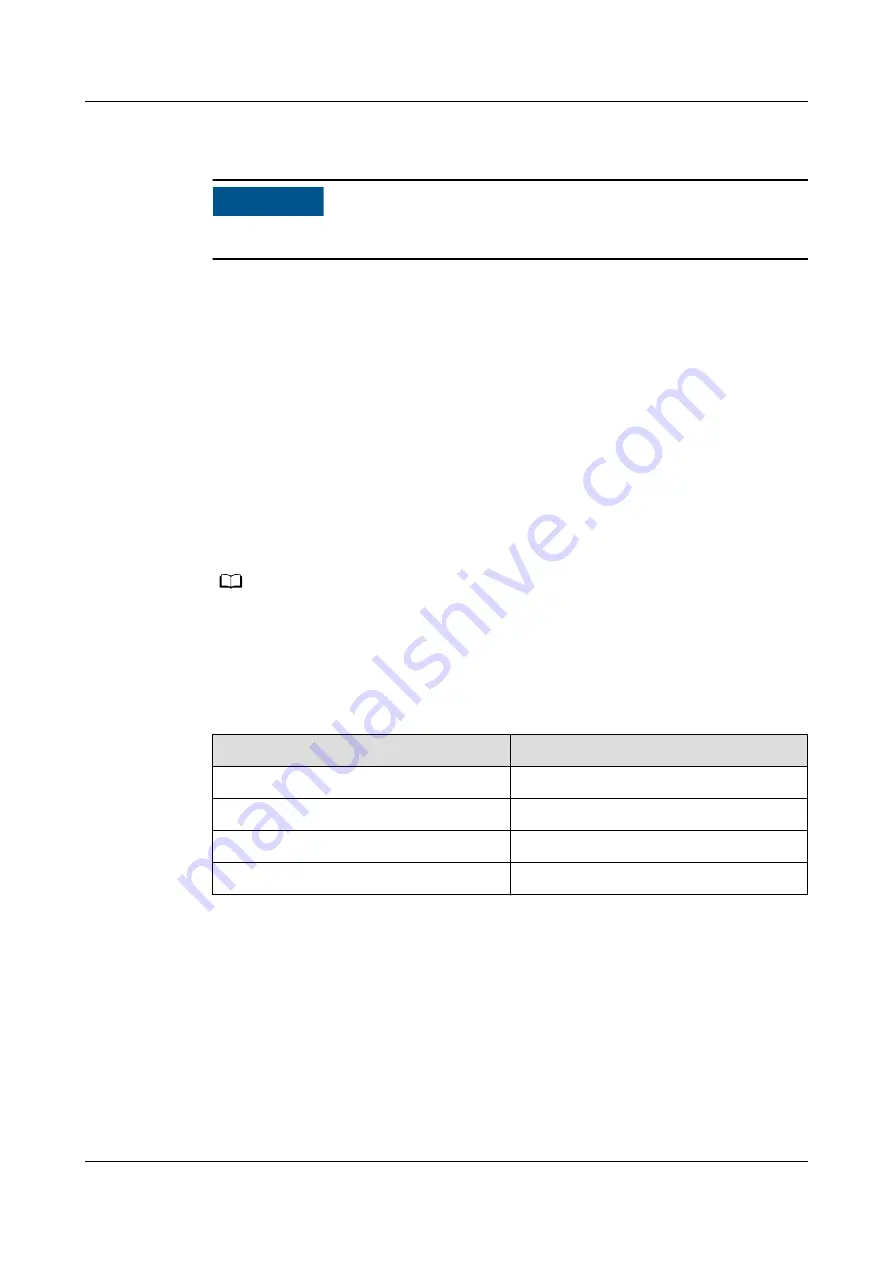

Table 6-9 Proper ranges of the air exhaust pressure

Outdoor Ambient Temperature

Exhaust Pressure Range

Below 15°C

1.5–2.5 MPa

15–35°C

1.5–3.1 MPa

35–45°C

2.5–3.8 MPa

Above 45°C

3.1–4.0 MPa

Step 11 Set Comp manual control to 0 rpm and click Submit.

Step 12 Choose Controls > Control Information, set Diagnostic mode to Exit, and click

Submit.

Step 13 Clear up the EEV total runtime.

●

Method 1: Log in to the ECC800-Pro mobile phone or pad app as user admin.

a. Choose Home.

b. Tap the cabinet that houses the smart cooling product in the micro-

module view.

FusionModule800 Smart Small Data Center

User Manual

6 O&M

Issue 01 (2021-02-05)

Copyright © Huawei Technologies Co., Ltd.

429