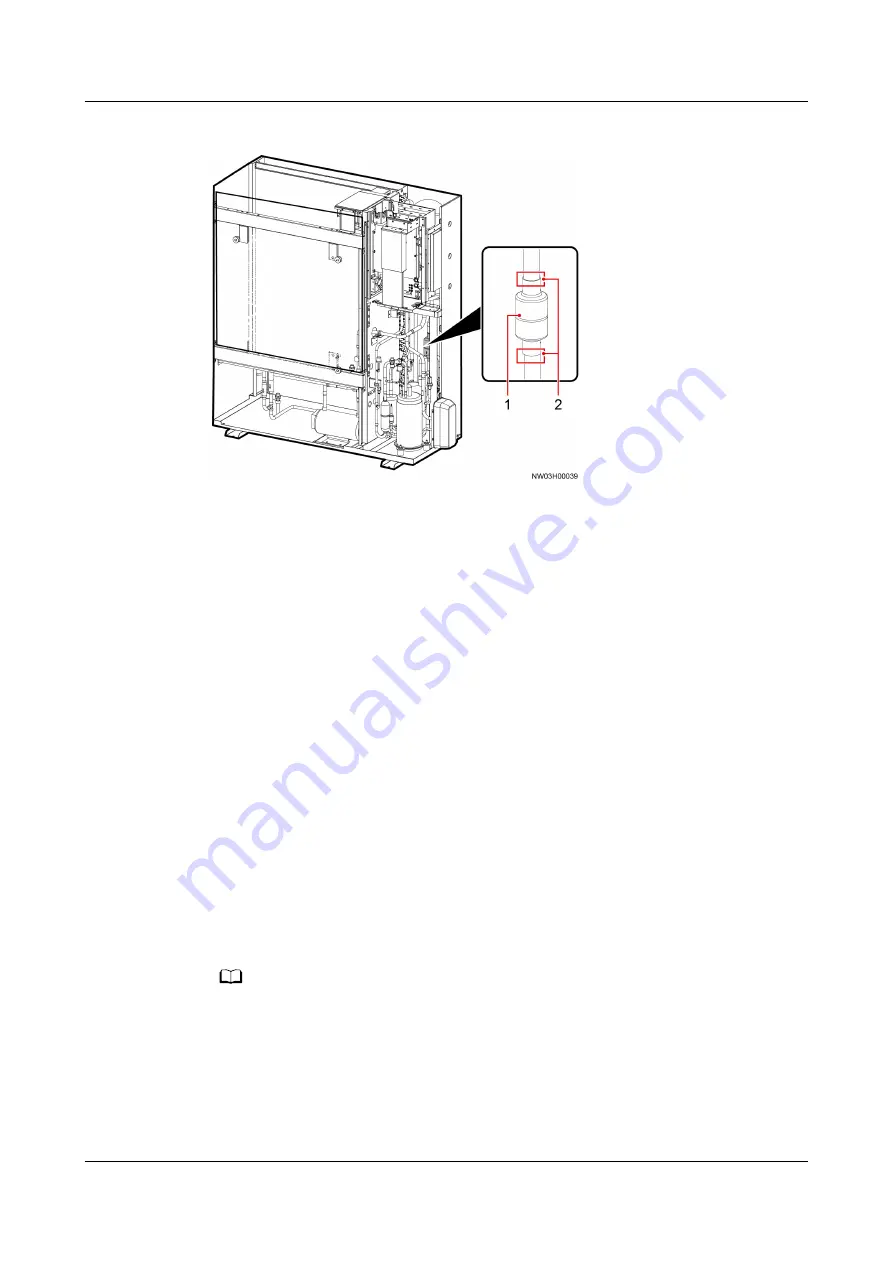

Figure 6-39 Position of the filter dryer (for NetCol500-A021)

(1) Filter dryer

(2) Welding point

Step 6 Weld the new filter dryer to the pipe.

Step 7 Secure the new filter dryer using cable ties.

Step 8 Perform a leakage test with nitrogen again. After checking that the smart cooling

product does not leak, vacuumize the smart cooling product and charge

refrigerant.

Step 9 Reinstall the left front panel and left rear panel.

Step 10 After powering on the smart cooling product, log in to the ECC800-Pro WebUI as

user admin, choose Monitoring > Cooling > NetCol5000-A1 > Controls >

Control Information, set Startup/Shutdown control to ON, and click Submit.

Step 11 Choose Controls > Control Information, set Diagnostic mode to Enter, and click

Submit.

Step 12 Choose Running Parameters > Diagnostic Mode Parameters, set Comp manual

control to 3000 rpm, and click Submit. Choose Running Info > Compressor

Information and read the air suction pressure and air exhaust pressure. Check

that the air suction/exhaust pressure of the compressor is within the proper range.

Choose Running Info > Electronic Expansion Valve Information. Check that the

EEV suction overheating degree is within the proper range.

NO TE

● The proper range of the suction pressure is 0.7–1.6 MPa, and the pressure ratio

(discharge pressure to suction pressure) is greater than 1.4.

● For details about the proper ranges of the air exhaust pressure, see

.

● The proper range of the air suction superheat degree is 4°C to 15°C.

Step 13 Set Comp manual control to 0 rpm and click Submit.

FusionModule800 Smart Small Data Center

User Manual

6 O&M

Issue 01 (2021-02-05)

Copyright © Huawei Technologies Co., Ltd.

449