Chengdu Huayuan Electric Equipment Co.,Ltd

LGK-40/63/100IGBT OPERATOR’S MANUAL

10

11

6

30

50

63

4 0

电 源 指 示

Power

Work cable

切割地线

Output air & current

气电输出

绝 缘 等 级 : F

防 护 等 级 : IP 21S

R

3

~

50 Hz

U

0

=270 V

U

1

=380 V

3 0A /9 2 V- 63 A /1 06 V

I

1 ma x

=15A

I

1e f f

=11.6A

X

I

2

U

2

60%

63A

106 V

49A

9 9.6V

100%

f

1

f

2

成 都 华 远 电 器 设 备 有 限 公 司

地 址 : 成 都 市 武 侯 区 武 侯 科 技 园 武 兴 四 路 5号

名 称 : 空 气 等 离 子 切 割 机

型 号 : L G K - 6 3 I G B T

出 厂 编 号

:

G B 1 5 5 7 9 . 1 - 2 0 0 4

冷 却 方 式 : 风 冷

重 量 : 2 6k g

3~

此 开 关 仅 作 保 护用

请 另 配 电 源 开 关!

Th is sw itc h is on ly us ed fo r Pro te ct ion !

输 入 3~ 380V

In pu t 3 ~38 0V

1

In ci se

切 割

切 割 电 流

Cutting current

试 气

Check air

供 电 异 常

Input fault

过 热

Overload

2

3

4

5

9

10

LGK-100IGBT

Control signal

控制

7

8

Strike arc line

引弧

12

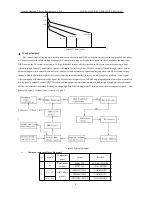

Figure 4 LGK-100IGBT Panel Function

1.

Power indicator lamp: Indicating if the cutter is energized.

2.

Power supply abnormality indicator lamp: It is ON when power supply is more than 440VAC or less than 300VAC

;

3.

Overload indicator lamp: It is ON when the cutter is over loaded

4.

Gas control selection switch: When it switches to Check air, gas valve opens to test gas flux. When it switches to Cutting, the gas

valve opens during cutting automatically.

5.

Cutting current adjusting knob: Adjusting cutting current

;

6.

Cutting ground wire outlet: To connect cutting ground wire

;

7.

Torch control outlet: to connect the torch control signal wire

8.

Air & Power output terminal: the current output terminal is also the compressed air output terminal. It is gas pipe connector to

connect water-cooled torch when the water-cooled torch is used, and it is connector to connect torch air-cooled cable when

air-cooled torch is used.

9.

Power source switch: Control the ON/OFF of 3-phase power supply of cutter.

;

10. Power source line

:

For connecting 3-phase power supply. The green-yellow line is used for protecting ground line, and it must be

connected to the ground firmly

;

11.

Air pressure regulation filter

:

For adjusting work pressure of compressed air and filtrating water from air.

12. Torch arc striking terminal: to connect torch arc striking wire (LGK-100IGBT)

Installation and Operation

1.

Transport and Lift

Power source should be shut off before moving the cutter.

The cutter bottom should be kept downwards during transportation. It is forbidden to have cutter placed transversely or upended.

When lifting, it must be lifted vertically.

During the long-distance transportation, it must prevent the cutter from raining and moving back and forth inside box. Shock

absorption foam should be placed around cutter.

2.

Installation and Connection

A . Power source should be shut off before installation and connection.

B. Installation environment details refers to the point “Work Environment Requirements”.

C. If cutting power source is placed in a slanted surface, it must be prevented from falling down.

D. Shield rank for cutting power is IP21S. The installation and operation cannot be proceeded in the rain.

Summary of Contents for LGK-63/100MA

Page 18: ......