Chengdu Huayuan Electric Equipment Co.,Ltd

LGK-40/63/100IGBT OPERATOR’S MANUAL

15

Troubleshooting & repair

1.

If there is trouble caused by high voltage in the machine, a professional electrician or serviceman of our company is

required to repair it.

2.

Please check following first when there is trouble.

1)

The three-phase power should be 380±40VAC

,

check if it misses phase or voltage fluctuation exceeds its required range of

power supply

;

2)

Check if the supply abnormity indicator lamp is ON. If it is ON, check if the three-phase power switch of distribution box is

damaged, and if the fuse and the machine power wire are well equipped. Otherwise it will cause phase missing or bad

contact, which makes the machine work abnormally

;

3)

Check if the torch switch and its wire are damaged or short-circuit, and if the nozzle and electrode are damaged

;

4)

Check if the cutting ground wire is well connected

;

5)

Check if the water in compressed air filter fixed at the back of machine is drained regularly

;

6)

Open the machine top cover to check if the lead-typed fuse next to the control transformer has been fused

;

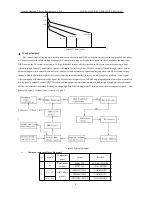

Ordinary trouble and repair as following diagram

If the troubles cannot be resolved, please inform our local agent of the specific problems or

contact us directly.

Trouble

Reasons

Solutions

1. When the power

is switched on, the

lamp and the digital

meter are not ON.

1.Three-phase power misses phase

2.Supply power is damaged

3.Power control fuse 1.5A is

broken

1.Check three-phase power source

2.Change power switch

3.Change power control fuse

2

.

Supply abnormity

indicator lamp is ON

without arc striking

1

.

Three-phase power misses phase

2. Three-phase power over voltage

or under voltage

Check three-phase power source to

ensure the supply voltage accordance

with the supply requirements.

3. No arc striking or

arc breaking during

cutting.

Overheat

indicator

lamp

is

ON.

1

.

The ambient temperature is too

high.

2

.

When cutting, cooling fan

rotates slowly or do not rotate, so

the cooling effect is bad.

3

.

Temperature relay is damaged

1

.

Let the cutter rest for a while, and

will come to work normally later.

2

.

Check fan power source or change

cooling fan

3

.

Change temperature relay

4. No arc striking,

supply

abnormity

indicator lamp and

overheat lamp are

not ON.

1

.

Cutting ground wire is not well

connected.

2

.

Gas pressure is too high.

3

.

Torch electrode and nozzle are

badly broken.

4

.

Torch is damaged.

1

.

Connect the cutting ground wire well

2

.

Lower the pressure of gas supply

3

.

Change the electrode and nozzle

4

.

Change the torch

5.

Weak

cutting

quality

1

.

Gas pressure is too high or too

low.

2

.

Workpiece is too thick

3

.

Torch electrode and nozzle are

broken

4

.

Plasma arc is not perpendicular

to the workpiece

5

.

Cutting speed is too fast or too

slow

1

.

Adjust gas pressure

2

.

The thickness of workpiece should

be within the quality cutting range.

3

.

Change electrode and nozzle

4

.

Adjust torch angle

5

.

Adjust cutting speed

Summary of Contents for LGK-63/100MA

Page 18: ......