6

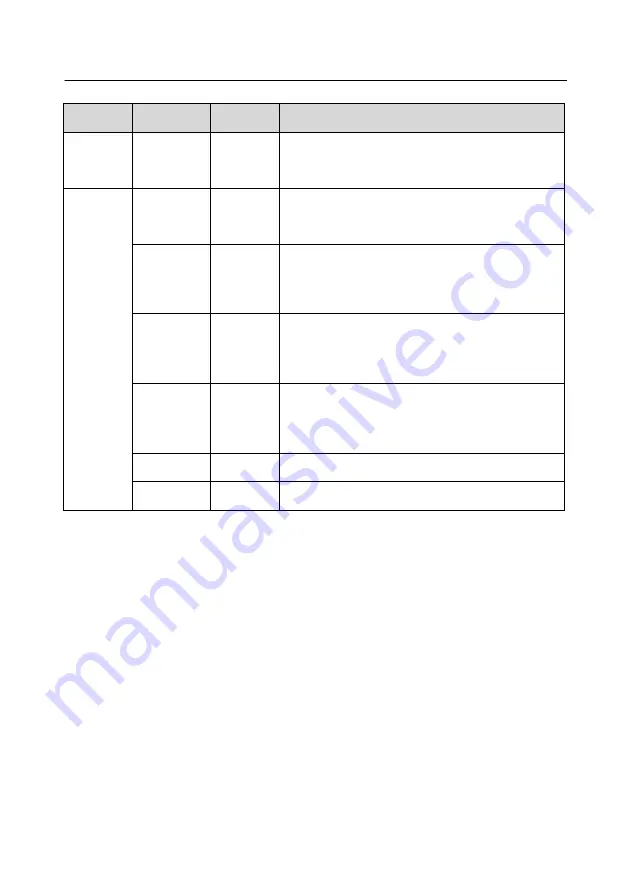

5. List of User Parameters

Level 1

Menu

Level 2

Menu

Initial

Value

Function

Start/Stop

Delay

Preset

Double

Rotation

0002H

In double-machine mode, if one host is working while

the other is idle in the system, the system makes the

working machine rest and the idle machine work when

it reaches the preset double rotation time.

Operation

Mode

Preset

Start/Stop

Mode

Local /

Remote

When set to Local, the air compressor cannot be started

or stopped by remote switch; when set to Remote, the

air compressor can be started or stopped by both

remote switch and local switch.

Loading

Mode

Auto /

Manual

When set to Manual, the loading and unloading of the

air compressor need to be operated manually after it is

powered on; when set to Auto, the air compressor

automatically loads and unloads according to pressure

after it is powered on.

Communica

tion Method

No/Comp

uter/Conn

ection

When set to No, communication does not work; when

set to Computer, it serves as a slave and communicates

with external devices according to MODBUS protocol;

When set to Connection, multiple air compressors can

be networked for running.

Communica

tion Code

0001

Used to set the communication address for connection

or communication with host computer;

When set for connection, the allowable range is 0-16;

when set for communication with host computer, the

allowable range is 0-99.

Host

Selection

Single /

Double

Single-host control or double-host control is optional.

Single-host

Operation

No.1 /

No.2

No.1 or No.2 host is optional.