4

(the connecting line should be as short as possible), connect the red end to the upper end

and the black end to the ground end.

2. After the power cord is connected, check whether the instrument and wiring are

correct, and then start the test.

3. Start the power switch, and the voltage will rise. Generally, the counter can start

checking when it is around 600V.

4. Press the check key and the current voltage is output. At this time, the action of the

counter can be observed.

5. If multiple tests are needed, press the check key when the output voltage reaches

the required value and observe the operation of the counter.

6. Turn off the power immediately after the inspection, and remove the connection

only when the output voltage returns to zero.

7. If the output voltage does not decline after pressing the check key, the power

should be turned off. After the voltage indicator returns to zero, check whether there is a

break point in the loop or whether the discharge counter is not suitable for the model

specified in the technical index.

VI.Matters Needing Attention

1. When dismantling the connection, if the output voltage does not return to zero, the

operator shall not touch the non-insulated part of the test line to avoid personal accident.

2. The tested product is not allowed to be charged.

VII.Packing List

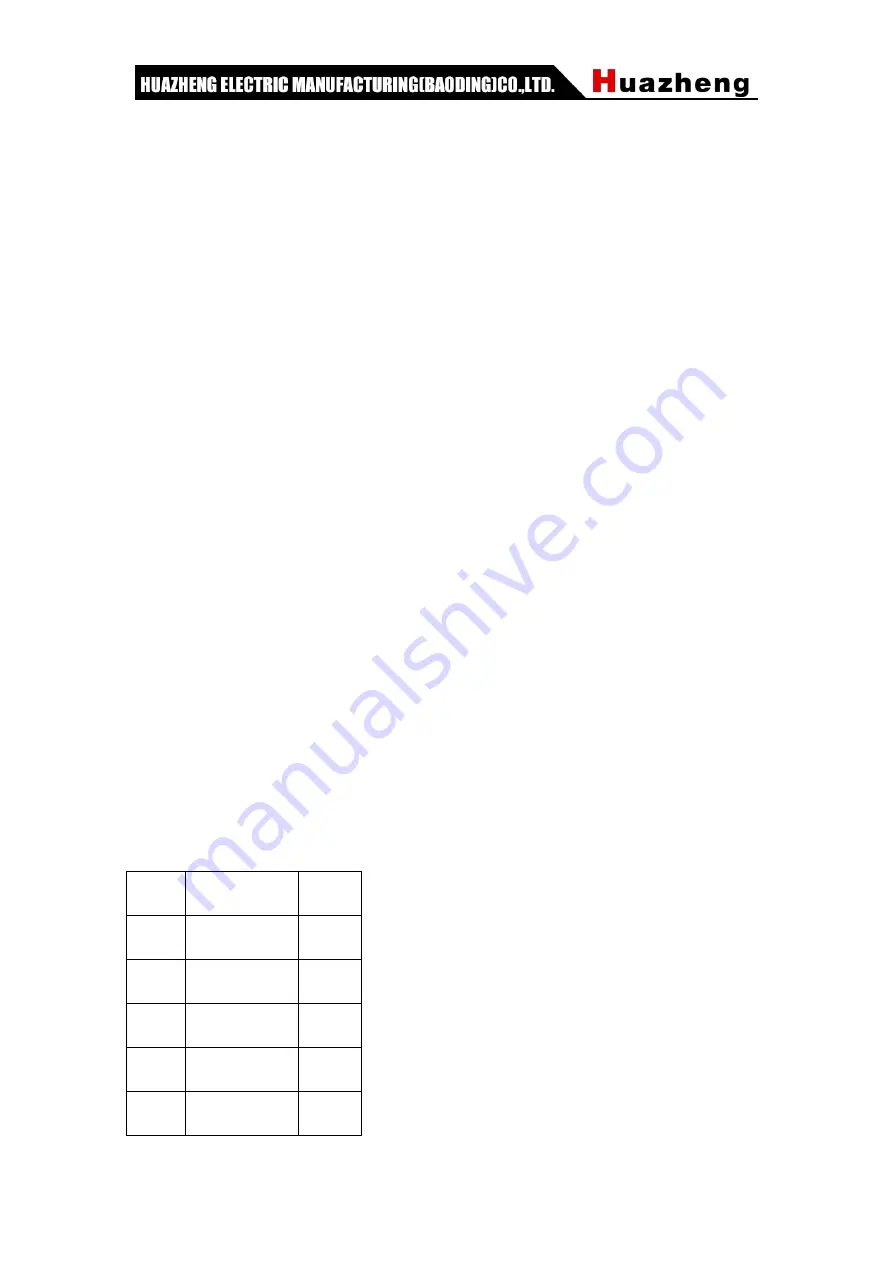

No.

Item

Qty

1

Main engine

1

2

Power line

1

3

Fuse pipe

2

4

Red test line

1

5

Black test line

1