14

Huba Control AG |

Industriestrasse 17, 5436 Würenlos - 699M - Edition 02/2020 -

120225

Technische Änderungen vorbehalten | Technical data subject to change | Sous réserve de modifications techniques

Configuration

The configuration of the device is made with Modbus®. Changes in registers for Modbus® parameters are only

effective as soon as

„1“

is inserted in the register 4x768.

Calculation of flow

Use the following formula for the calculation of flow:

Q = k * √∆

Δ

p

Q = flow rate

k = k-factor

Δ

p = differential pressure

Attention:

The k-factor depends on the geometry of the change of cross section which detects the volume flow

Use in combination with commercially available standard products (measuring orifice, filter, ventilation etc.) consider

the corresponding manufacturer instructions.

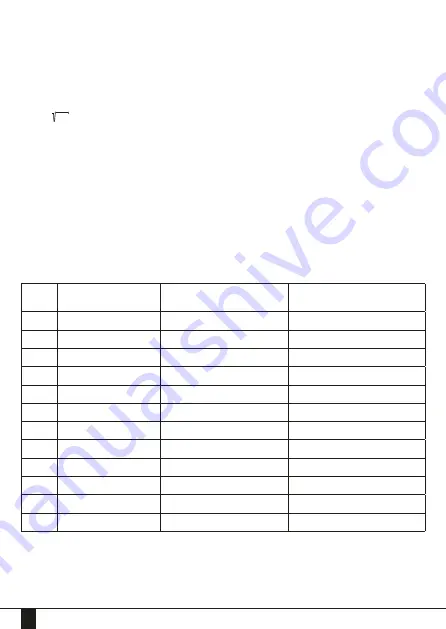

Fault correction

The status-LED blinking red allows a readout of the error codes as well as of the status register information about the

current failure. A regular readout of the register provides a early error detection. Please consider the following chart.

Value

Error Code

(register 4x0002)

Status register pressure sensor

(register 4x0006)

Status register analog inputs

(register 4x0010)

0

no error

no error

no error

1

no sensor

disruption in operation

sensor not connected

2

overload

overload

temperature > 150ºC

3

underload

temperature < -40ºC

4

open loop

5

short time overload

short time overload

6

no output signal

7

other error

zero point reset required

8

calculation error

9

extended error

10

EEPROM protection active

11

configuration error

configuration error

configuration error