Manual M-800 Rev. 6/09

Manual M-800 Rev. 6/09

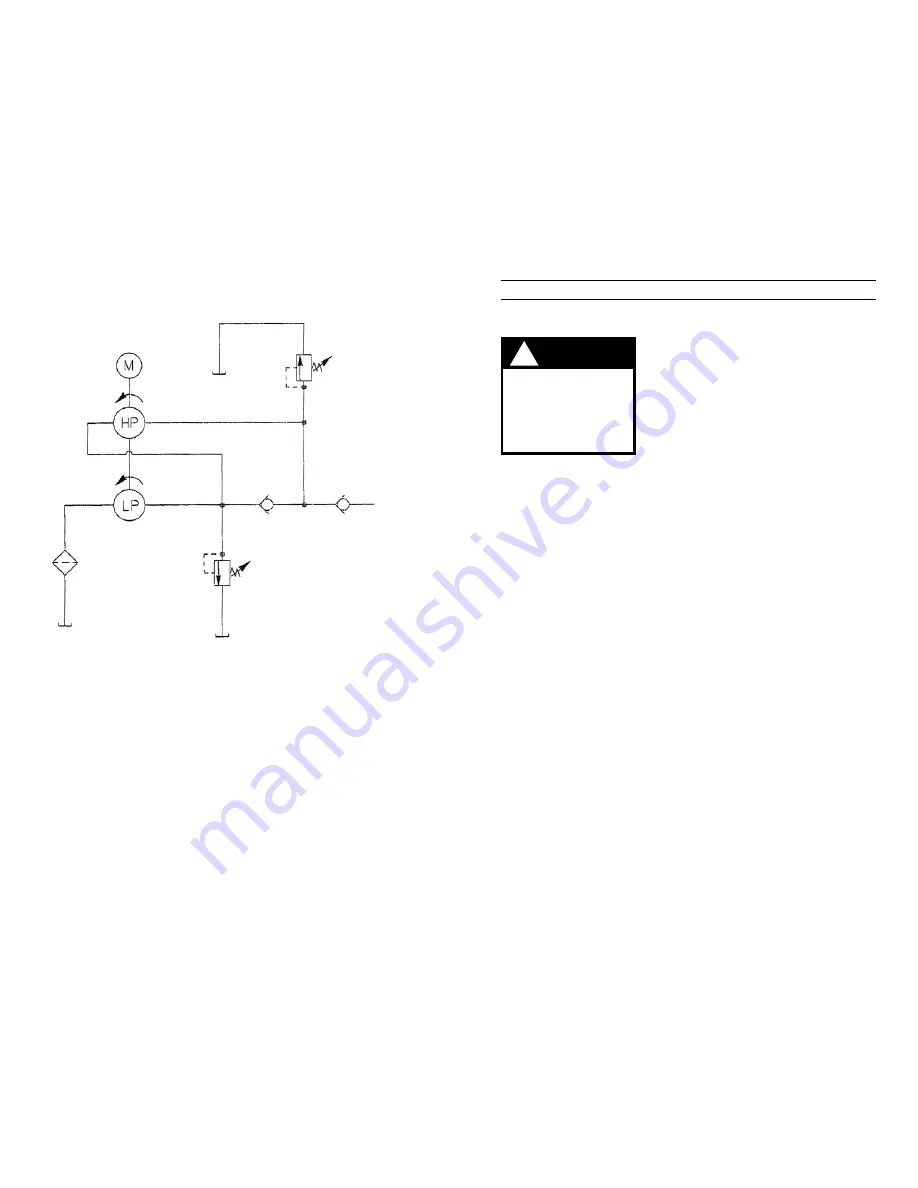

HYDRAULIC SCHEMATIC

MAX. PRESSURE

SAFETY RELIEF VALVE

REFER TO YOUR

PUMP’S NAMEPLATE

SUPERCHARGE

RELIEF VALVE

260 / 280 PSI

TO VALVE

Page 8 of 16

PROBLEM

CAUSE

SOLUTION

Electric motor does not run.

1. Unit is not plugged in.

2. No voltage supply.

3. Broken lead wire or de-

fective power cord plug.

4. Defective switches.

5. Defective started relay.

6. Defective remote switch.

7. Circuit breaker tripped

because total amperage

draw too high for existing

circuit.

8. Overheated motor.

9. Faulty thermal protector.

10. Defective motor

1. Plug in unit.

2. Check line voltage.

Check reset button on

power panel.

3. Replace defective parts.

4. Replace switches.

5. Replace defective parts.

6. Replace remote switch.

7. Add an additional circuit

or use alternate circuit.

8. Wait for motor to cool

before restarting.

Thermal protector will

reset automatically, or

push red reset button

on tip of the motor (if so

equipped).

9. Replace.

10. Replace or repair motor.

Disconnect power sup-

ply before removing

cover. Any electrical

work should be per-

formed by a qualified

electrician.

WARNING

!

Page 9 of 16