P/N KIL00921328 FORM NO. K1328 07/17 ECO-4-010-16

Page 1 of 8

MAINTENANCE DATA

After installation, this enclosure should be inspected at regular intervals. A visual inspection should ascertain that all

cover bolts are still tight; that all conduit connections are intact and free of corrosion, and that the enclosure mounting

bolts are tight and in good condition.

HUBBELL ELECTRICAL PRODUCTS

A Division of HUBBELL INCORPORATED (Delaware)

3940 Martin Luther King Drive

St. Louis, Missouri 63113 USA

INSTALLATION, OPERATION & MAINTENANCE DATA SHEET

B7NFD COMPACT SERIES IEC DISCONNECT INSTALLATION

For use in Class I, Groups B, C & D, Type 3, 4 & 4X and Class II, Groups E, F & G, and Class III Hazardous

Locations, as defined by the Canadian Electrical Code and the National Electrical Code.

READ THIS SHEET CAREFULLY BEFORE BEGINNING INSTALLATION.

IMPORTANT:

This enclosure and device

must

be installed by trained, qualified and competent personnel.

Installation

must

comply with local, state and national regulations, as well as safety practices for this type of equipment.

WARNING:

Electrical power

must

be

OFF

during installation, or performing any maintenance.

Disconnect

primary power

source and

lock out

.

The mounting location must be flat and provide proper clearance, rigidity and strength to support the enclosure and all

contained devices.

Securely fasten the enclosure to the mounting location. Install sealing fittings, cable glands, unions and/or conduit, using

an approved electrical conducting type lubricant on the threads. The conduit thread connections must be tapered pipe

thread conforming to ANSI B1.20.1. A minimum of (5) full threads engagement is required for all conduit connections.

Conduit sealing fittings must be installed within 18 inches of the enclosure. Sealing fittings must be approved for the

specific hazardous location where the enclosure is used. All unused conduit openings must be plugged using Killark

“CUP” close-up plugs. Plugs must be tightly installed with a minimum engagement of (5) full threads.

NOTE: If installing a breather and/or a drain, make certain they are suitable for the specific hazardous location where

they are to be used. Some drains/breathers may not comply with Nema 3 & 4 standards. Also, provide a protective

covering to shield the breather and drain during hose-down operations.

For “factory complete” units, follow the instructions at

● and dis-regard the mounting instructions/drawings.

If

not

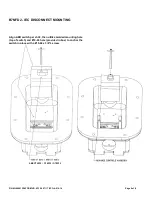

a “factory complete” unit, install the IEC Disconnect of your choice per the instructions provided with the device and

the drawings shown on following pages. In the drawings, locate manufacturer of device being installed and note the

specific holes being used to mount device din rail into enclosure box. The din rail numbers correspond with a mounting

location in the enclosure box and are specific to each device. Install din rail in correct location, then install and align

Disconnect and end blocks (where needed) onto din rail, following the drawings provided. Secure end blocks

permanently on both sides of disconnect by using a screw driver and tightening the recessed screws. Cut “square shaft”

(21872) provided, to the over-all length dimension shown in the chart on page 3, for the specific device being used.

(NOTE: smooth out the cut edge of the shaft). Insert the cut shaft, allowing it to rest at the bottom of the device interface

opening and in the orientation shown in the “Disconnect Mounting” pictures that follow.

● Wire the Disconnect as required. Factory installed rotary operator is mounted into cover and aligned at the factory to

interface with Disconnect, once din rail and enclosure cover are installed onto box.

▲ Inspect and clean the machined flange flame joint surfaces of both the cover and the box. Surfaces must be smooth,

free of nicks, scratches, dirt or any foreign particle build-up that would prevent a proper seal. Surfaces must seat fully

against each other to provide a proper explosion-proof joint. Clean surfaces by wiping with a clean, lint-free cloth.

Apply a light coating of Killark “LUBG” lubricant to flange surfaces and close the cover. Tighten all cover bolts. Use only

those bolts supplied with the enclosure. Check the bolted joint with a .0015 thick feeler gauge. The gauge must not

enter the joint more than 1/8” at any point.

NOTE:

Loose bolts or an improper joint can result in an explosion, creating a

potential for physical injury and property damage.