position.

2. Push the test button on the individual GFCI

module. The unit should trip.

3. Push the reset button. The indicator light

should come on.

4. Repeat steps 2 & 3 for the remaining six

modules.

Models SDSB2 and SDTL2

only, equipped

with (1) 30 Ampere GFCI circuit breaker.

1. Push the test button. The unit should trip.

2. Reset the breaker by pushing handle to the

“OFF” position, then to “ON”.

If the unit does not trip when tested, or cannot

be reset after conducting the recommended

troubleshooting procedure, consult Hubbell

Incorporated, Milford, Connecticut.

TROUBLESHOOTING THE SPIDER II

The main power contactor within the SPIDER II

unit will trip whenever one or more of the

following abnormal conditions exist in the line

(supply) side circuit:

1. Either line (hot) conductor is transposed with

the neutral conductor.

2. Either line (hot) conductor is open

(disconnected).

3. There is an excessive voltage imbalance

between line 1 and line 2 circuits. This may

be the result of an open neutral conductor in

the supply circuit.

When the abnormal condition(s) in the supply

circuit is corrected, the unit may be reset for

normal use by completely removing and then

reapplying line power. It is recommended that

the GFI test procedure be repeated at this time.

When a GFI module trips, attempt to reset it by

pressing the reset switch, being careful to look

for possible danger to personnel. If the module

resets, the fault was momentary and has

cleared. If it trips again immediately, the fault is

still present and the GFI module is performing its

safety function. To locate the fault, disconnect

all loads and again try pressing the reset switch.

The module should reset. Reconnect the loads

one at a time. The module will trip when the

faulted load is reconnected. Inspect all tools,

appliances and extension cords in the faulted

load circuit, repairing or replacing any that are

not in good condition.

NOTE:

Tripping of a branch circuit breaker in

the models can only result from an overload or

short circuit condition in its individual load circuit.

When the fault in the load circuit is corrected

or removed, the circuit breaker can be reset

for normal use by turning handle to “OFF”

position and then to the “ON” position.

Models SDTL2 and SDSB2 only

A GFI circuit breaker will trip whenever one or

more of the following fault conditions exist in

its individual branch circuit:

1. A ground fault occurs (the leakage current

to ground exceeds 5 milliamperes).

2. The neutral conductor becomes grounded.

3. There is an overload or short circuit.

When a GFI circuit breaker trips, attempt to reset

it by turning its handle to the “OFF” position then

to the “ON” position. If it resets, the fault was

momentary and has cleared. If it trips again, the

fault is still present and the GFI breaker is

performing its safety function. To locate the

fault, disconnect all loads on the branch circuit

in question. (Note that this corresponds to only

one outlet on the SPIDER

®

II UNIT. A load of more

than one tool or appliance on a given branch

circuit can only be achieved using multiple outlet

taps, strips, or extension cords, or through a

feed-through receptacle(s) built into an

appliance). Reset the GFI breaker and reconnect

the loads one at a time. The breaker will trip

when the faulted load is reconnected. Inspect

all tools, appliances and extension cords in the

faulted circuit, repairing or replacing any that

are not in good condition.

NOTE:

If a GFI circuit breaker trips as the result

of an overload condition, it may not trip

immediately after the load has been disconnected

and then reconnected because the thermal

sensing element has cooled. For example, the

breaker is permitted to take up to one hour to trip

off when carrying 135 percent of its rated load

(40.5 amperes on a 30 amp circuit).

When the fault in the load circuit is corrected or

removed, the GFCI circuit breaker should be

reset for normal use.

APPLICATION NOTES

1. Tripping of individual branch circuit breakers

in any SPIDER II unit has no effect on

downstream units connected through the

30 amp outlet.

2. There is no overload protection for the 30

amp outlet.

3. When shutting down the temporary power

at the end of the working day, do so by

pressing the test button on the individual

modules on the SPIDER II unit and the individual

GFI breaker test buttons for models SDTL2,

SDSB2.

NUISANCE TRIPPING

All cables have some capacitive leakage.

In a 120 V system, there is a limit to the

length of cable which can be run before

sufficient leakage to ground will build up

causing a GFI to trip. In the Hubbell SPIDER

II system, however, capacative leakage in

the two power lines flows in opposite

directions. This design cancels the

capacative leakage effect, and there is no

theoretical limit to the length of

interconnecting cable runs between SPIDER

II units. Individual 120 volt branch circuit

load cords, however, should be limited to

250 feet in length.

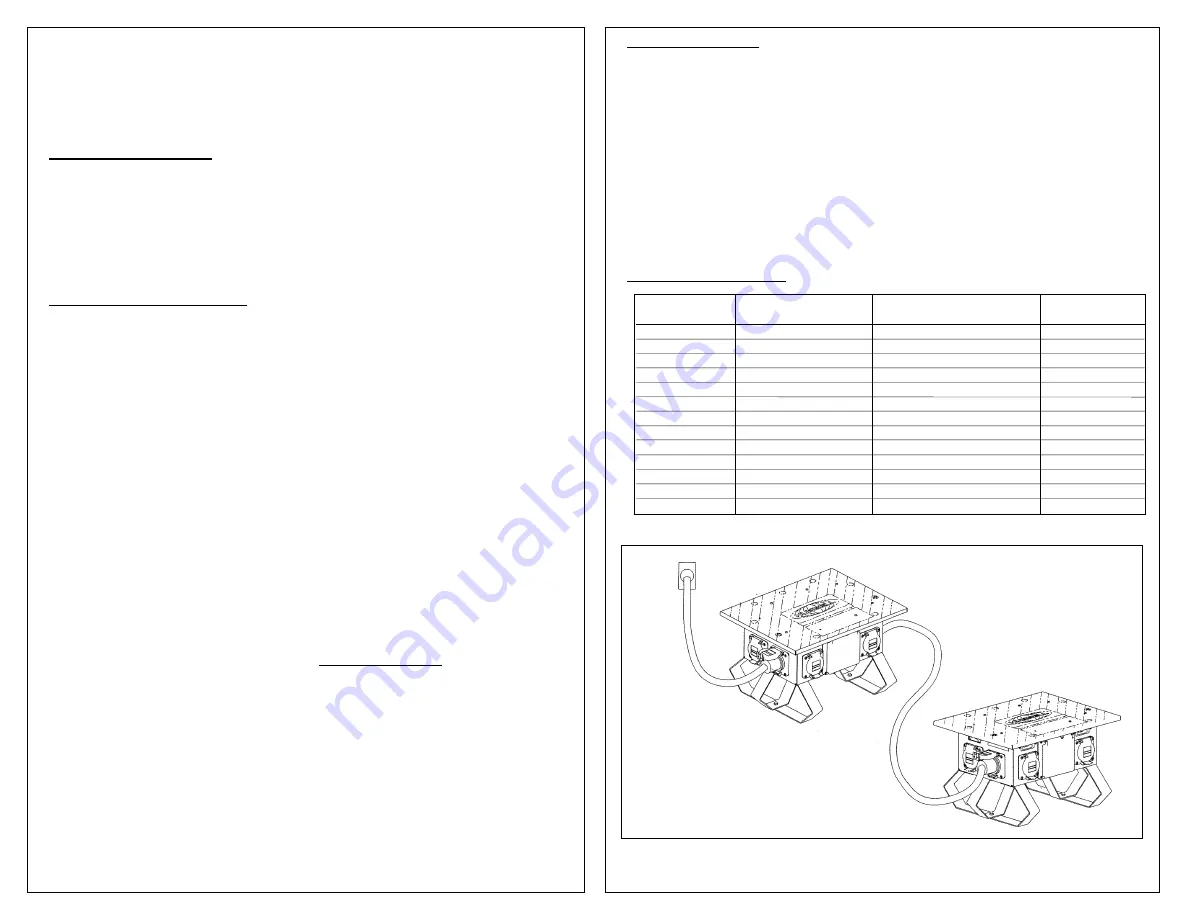

MAINTENANCE & REPAIR

Replacement

Part

Manufacturer

Device

Description

Number

HUBBELL

Receptacle

20 A 125 V Twist-Lock

HBL2310SW

HUBBELL

Receptacle

20 A 125 V Straight Blade

HBL53R61

HUBBELL

Receptacle

30 A 250 V Twist-Lock

HBL2620SW

HUBBELL

Receptacle

30 A 125/250 V Twist-Lock

HBL2710

HUBBELL

Inlet

30 A 125/250 V Twist-Lock

HBL2715SWR

HUBBELL

Supervisory Module

Polarity Supervisory Circuit

SSK

HUBBELL

GFCI Module

20 A 120 VAC

GFM20

HUBBELL

Cover

Circuit Breaker

SCBC

HUBBELL

Cover

Receptacle

HBL74CM25WOA

HUBBELL

Legs

Replacement Leg Kit

SLK

General Electric

Circuit Breaker

20 A Single Pole

THQL1120

General Electric

Circuit Breaker

30 A Double Pole w/ GFCI

THQL2130GF

HUBBELL

Connector, reverse service

30 A 125/250 V Twist-Lock

HBL2713SR

SPIDER and Circuit Guard are registered trademarks of Hubbell Incorporated.

SPIDER

®

II

CAUTION:

Electrical power supply MUST

BE OFF AND DISCONNECTED before and

during any repair or maintenance. Repair

and maintenance must be performed by a

trained and competent electrician.

WARNING:

If any parts or components of

Spider II unit appear to be missing, broken or

show signs of damage, DISCONTINUE USE

IMMEDIATELY! Do not modify these devices

in any way. Replace worn or damaged

components. Failure to do so could cause

serious personal injury and/or equipment

damage.

NOTICE:

REMOVE PROTECTIVE PLASTIC FILM ON COVER AND DISCARD PRIOR TO USE.