Introduction

OPERATION MANUAL

Chapter 1

Unichiller® eo Desktop

V2.2.0en/09.08.21//17.12

18

▪

Regular leak tests of stationary refrigeration systems by certified personnel (such as Huber service

engineers). The required test interval is based on the refrigerant filling capacity and the type of

refrigerant, converted to CO

2

2 equivalent.

▪

Responsibility of responsible bodies operating a plant to recover F-gases by certified personnel.

▪

Obligatory documentation requirement in the refrigeration system’s operation manual, specifying

type and volume of refrigerant used or recovered. The responsible body must keep the records

for at least 5 years after their creation and present it to the responsible authority upon request.

▪

Temperature control units with natural refrigerants (NR) are exempt from this Directive.

▪

Please refer to the data sheet or rating plate of your temperature control unit for the quantity

and type of refrigerant.

▪

Additional information about the definition of the inspection interval can be found on our web-

site.

1.4.2

Requirements for operators

Work on the temperature control unit is reserved for appropriately qualified specialists, who have

been assigned and trained by the responsible body to do so. Operators must be at least 18 years old.

Under 18-year olds may operate the temperature control unit only under the supervision of a quali-

fied specialist. The operator is responsible vis-a-vis third-parties in the work area.

1.4.3

Obligations of the operators

Carefully read the operation manual before operating the temperature control unit. Please observe

the safety instructions. When operating the temperature control unit, wear appropriate personal

protective equipment (e.g. safety goggles, protective gloves, non-slip shoes).

1.5

General information

1.5.1

Description of workstation

The workstation is located at the control panel in front of the temperature control unit. The work-

station is determined by the customer's connected peripheries. Accordingly, it must be designed

safe by the responsible body. The workstation design also depends on the applicable requirements

of the German occupational health and safety regulations [BetrSichV] and the risk analysis for the

workstation.

1.5.2

Safety devices to DIN 12876

The rating of your temperature control unit is stated on the data sheet in the appendix.

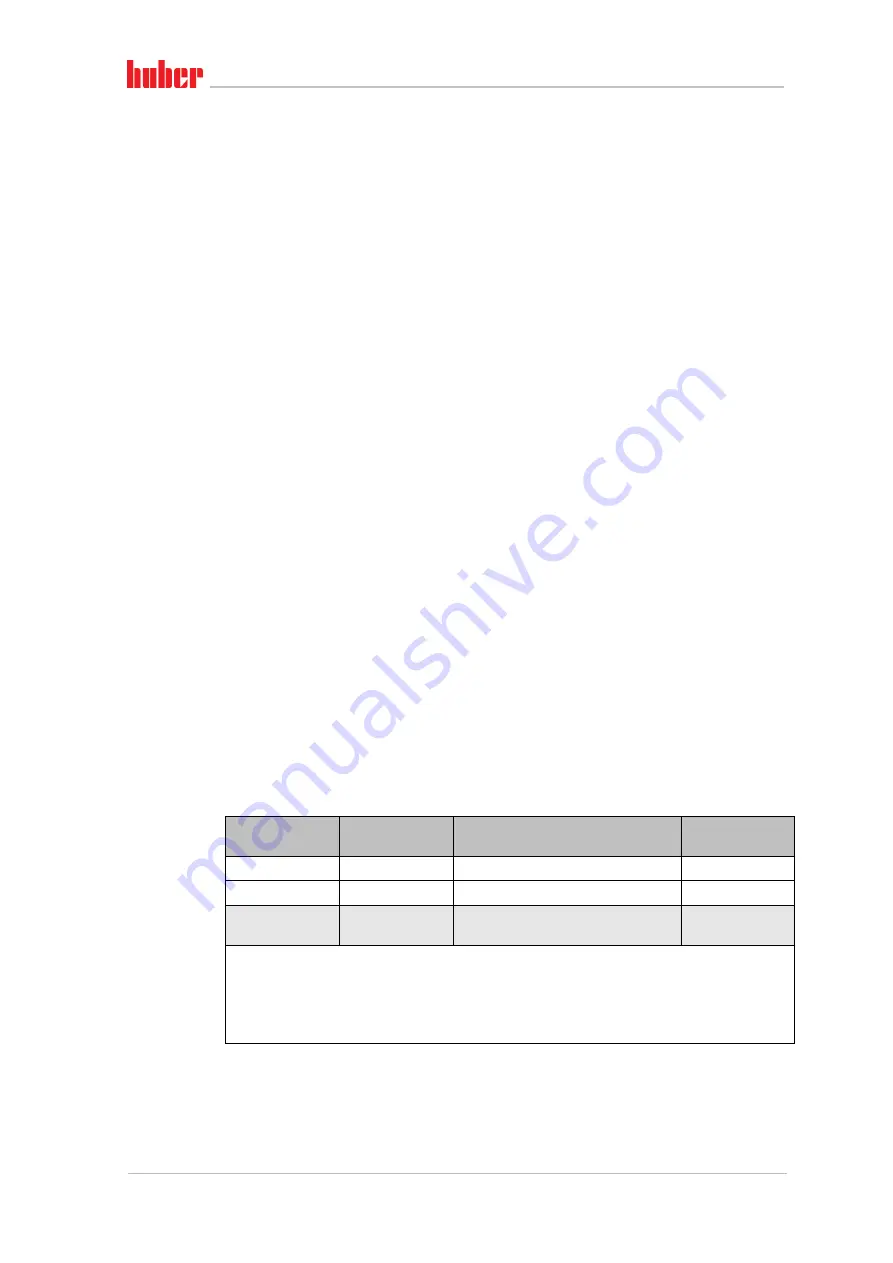

Classification

Temperature

control medium

Technical requirements

Identification

d)

I

Non-combustible

a)

Overheat protection

c)

NFL

II

Combustible

b)

Adjustable overheat protection

FL

III

Combustible

b)

Adjustable overtemperature protection

and additional low-level protection

FL

a)

Usually water; other fluids only if non-combustible even within the temperature range of an individual fault.

b)

The temperature control media must have a fire point of ≥ 65 °C.

c)

The overheat protection can, for instance, be realized using a suitable fill level sensor or a suitable temperature

limiter.

d)

Optional at the choice of the manufacturer.

▪

Temperature control units with heating correspond to class number III/FL. These temperature

control units are characterized by an “H” in the device name.

▪

Temperature control units without heating correspond to class number I/NFL.

Rating of laboratory

thermostats and

laboratory baths