Interfaces and software update

Chapter 6

OPERATION MANUAL

V2.2.0en/09.08.21//17.12

Unichiller® eo Desktop

69

the alarm function is wanted together with the operating current principle.

▪

“Unipump/PCS”:

This POKO function and the enable contact of the pump guarantee that the

external pump runs synchronously with the pump in the temperature control unit if an external

pressure booster pump is used in your temperature control circuit / cooling water circuit, i.e. the

POKO assumes the OK state as soon as the internal pump is started up.

PCS: The POKO is used to communicate the state of the temperature control unit to the process

control system.

POKO condition

ON

means the pump is running.

POKO condition

OFF

means the pump is not running, the temperature control unit is in stand-by

mode.

▪

“External control”:

The PB commands “vPoKoExtMode” and “vPoKoState” use an external inter-

face (Ethernet, RS232, TS485, USB device) to switch the POKO on and off. Please also refer to the

software offered by us and the Data Communication Manual.

▪

“Process temperature relative”:

Set the upper and lower limit of a temperature range around the

setpoint by using the POKO “min. value” and the POKO “max. value”.

The potential-free contact indicates the condition, that the setpoint differs from the actual value

by a smaller difference than was defined by the temperature range. Exceeding the set range only

results in the potential-free contact to switch (away from the OK state), but does not result in fur-

ther reactions of the temperature control unit. The contact returns to the OK status if the actual

value is within that range.

▪

“Unipump with Echo”:

This function is used to check whether the Unipump controlled by the

POKO runs synchronous with the Unistat pump. For this purpose, the operating mode of the

Unipump is applied via a make contact to the “LEVEL” socket. A fault is generated if asynchro-

nous. This mode is useful if a Unipump is to be monitored - either to guarantee the desired circu-

lation or to prevent an unintended heating of the thermal fluid.

▪

“Programmer”:

This activates the individual segments associated during program creation with

the POKO switching states.

▪

“Internal temperature absolute”:

This enables you to set a temperature range relative to the

internal sensor (absolute temperature). The POCO is active outside of this range; the POCO is in-

active inside of this range.

▪

“Process temperature absolute”:

This enables you to set a temperature range relative to the

process temperature (absolute temperature). The POCO is active outside of this range; the POCO

is inactive inside of this range.

▪

“Solenoid valve flow / return flow”:

This function is used to control a connected solenoid valve. It

takes 60 seconds before the POKO switches on after you have started the pump in the tempera-

ture control unit. For example, the POKO is switched off before the pump has been completely

stopped when the temperature control process / circulation is stopped. Thus, the POKO is

switched on only as long as the full pump pressure exists.

▪

“Cooling”:

This function is used to open the cooling water supply with a solenoid valve only when

the temperature control unit requires cooling water. The POKO is switched on when the tempera-

ture control unit is cooling.

▪

“Message available”:

The POKO switches on when a message is available at the Pilot ONE. This

message can be a fault, warning or general message.

▪

“Automatic filling”:

The POKO switches on when the level has dropped below the minimum

value. The POKO is switched off after 20 seconds when the level has risen above the minimum

value. The POKO switches off immediately when the maximum value has been reached.

With the floating contact, use only sheathed lines! The interface is specified as a digital output.

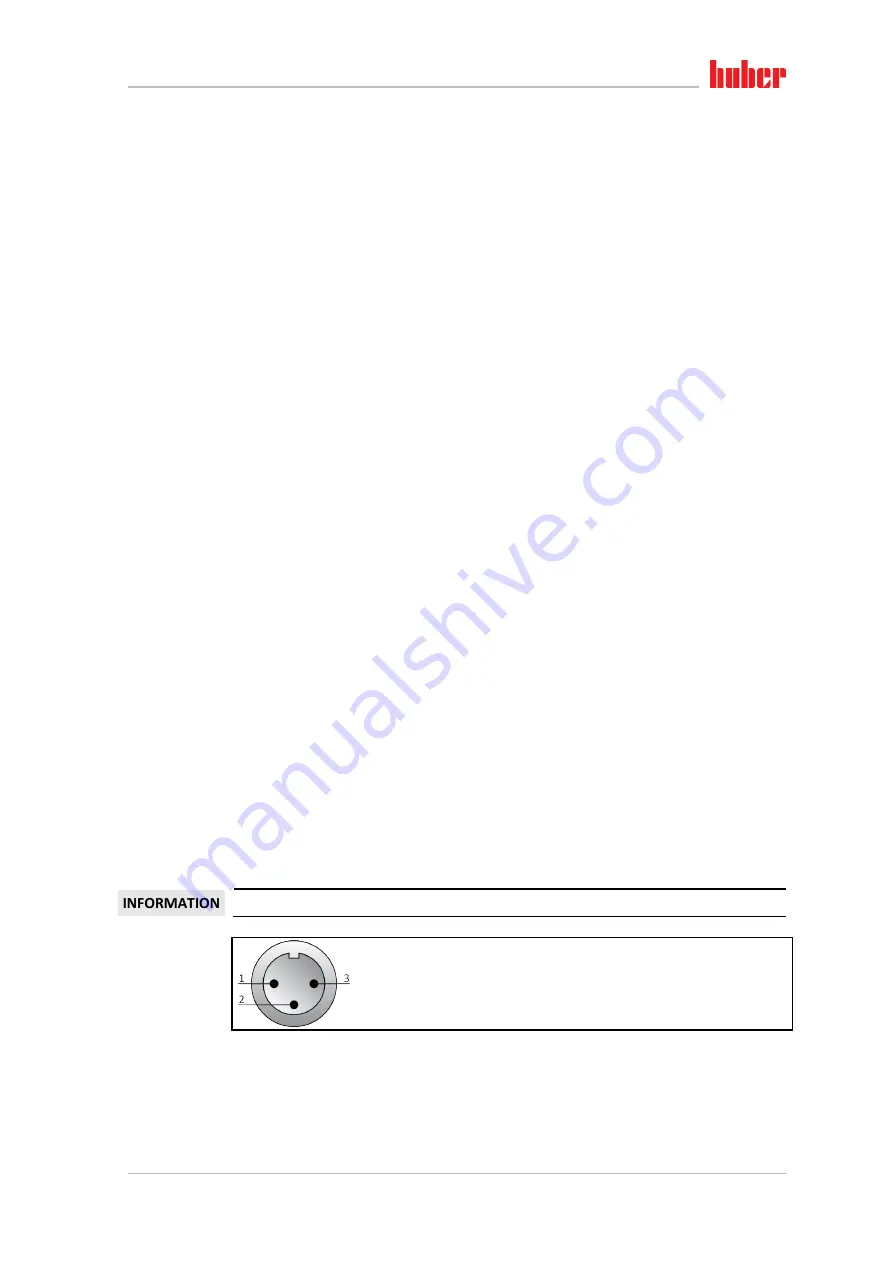

The connection is designed as a potential-free changeover contact.

Closing contact between pin 1 and pin 2.

Opening contact between pin 2 and pin 3.

Contact load: 1 A at 24 V DC.

Pin assignment (front

view)