EN - ENGLISH – 01/2020

Translation of original instructions

18

EN

Reproduction is prohibited

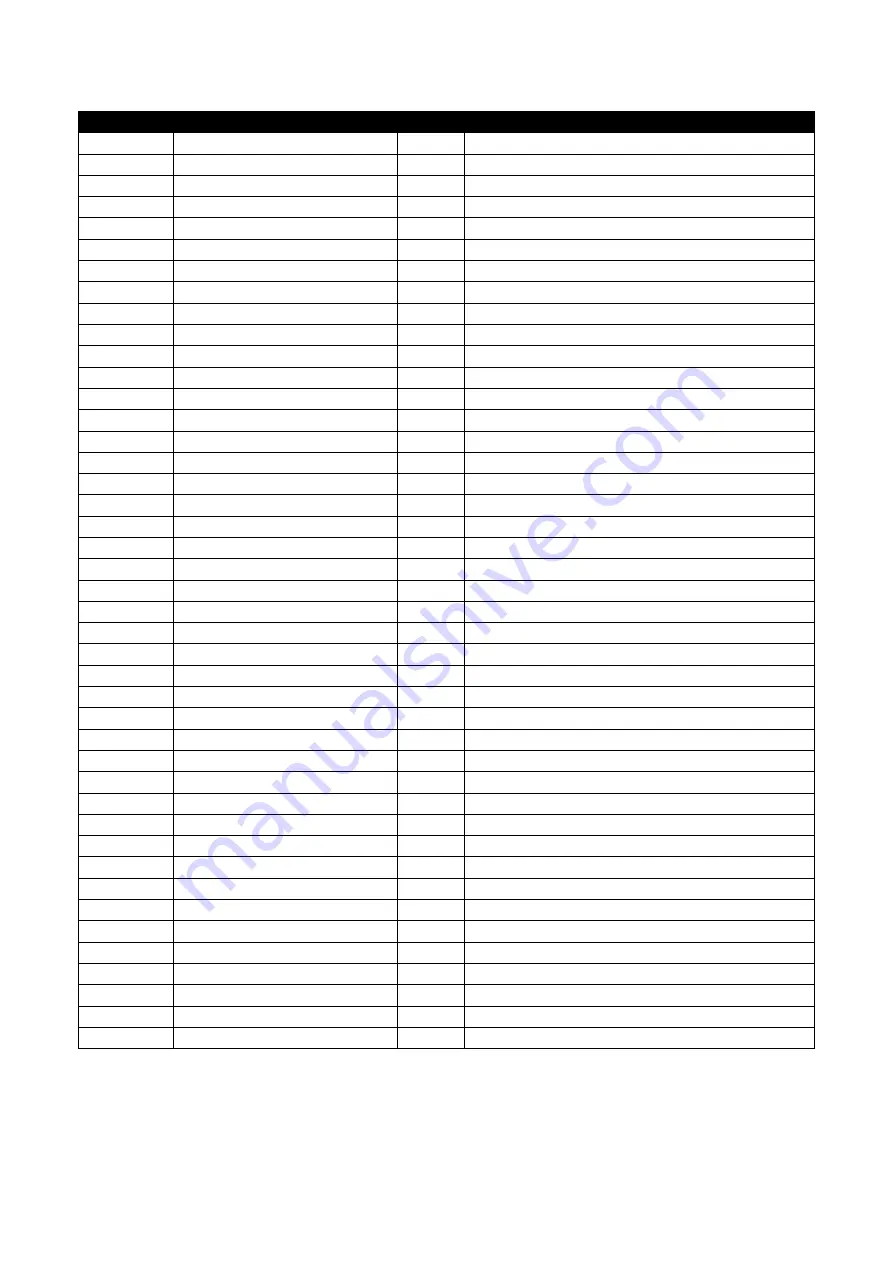

No.

Part No.

Qty

Description

1

N1750001

3

Terminal protector

2

N1750002

4

Screw M8 x 25

3

N1750003

4

Lock washer

Φ8

4

N1750100

1

Motor assembly

5

N1750004

6

Screw M10 x 30

6

N1750005

6

Lock washer

Φ10

7

N1750006

1

Motor gasket

8

N1750007

2

Ring seal

9

N1750008

2

Bushing drum

10

N1750200

1

Brake/shaft assembly

11

N1750009

1

Six angle bar

12

N1750010

1

Coupling

13

N1750300

1

Drum

14

N1750011

1

Screw M8×10

15

N1750012

3

Tie bar

16

N1750013

10

Screw M8 x 75

17

N1750014

10

Lock washer

Φ8

18

N1750003

1

End bearing

19

N1750015

2

Gasket

20

N1750016

1

Gear - ring

(

Output

)

21

N1750400

1

Gear carrier assembly (output)

22

N1750017

1

Circlip for hole

23

N1750500

1

Gear carrier assembly (intermediate)

24

N1750018

1

Gear - ring

(

intermediate

)

25

N1750600

1

Gear carrier assembly (input)

26

N1750019

1

Gear - input

27

N1750020

1

Shaft sleeve

28

N1750021

1

Trust washer

29

N1750700

1

Clutch

30

N1750022

1

Gear housing

31

N1750023

8

Screw M12×30

32

N1750024

8

Lock washer Ø12

33

N1750025

2

Lock washer Ø5

34

N1750026

2

Screw M5×10

35

N1750800

1

Control box

36

N1750027

2

Screw M10×35

37

N1750028

2

Lock washer Ø10

38

N1750029

2

Flat washer Ø10

39

N1750900

1

Roller fairlead

40

N1750030

2

Nut M10

41

N1751000

1

Switch

(

RC3

)

42

N1751100

1

Cable

43

N1750031

1

Strap