EN - ENGLISH - 09/2019

Translation of original instructions

9

EN

Reproduction is prohibited

07

MOUNTING - INSTALLATION

Accessories you will need which are not included with the winch:

•

Gloves for handling the cable and hook safety strap.

•

Anchoring sling/chain.

•

Blanket to throw over the cable to absorb the energy if the cable breaks.

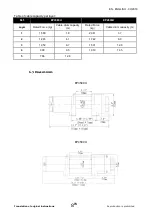

1. The winch is designed with a standard bolt pattern for this class of winch. Many winch

mounting kits use this bolt pattern for common vehicles and mounting plates. If you wish to use

a mounting plate, ensure that it is mounted on a flat surface so that the motor, drum and

gearbox housing are correctly aligned. Correct alignment of the winch will ensure uniform

distribution of a rated load.

2. Begin by assembling the roller fairlead and the mounting plate using 2 screws. Ensure that the

screws are inserted through the mounting plate from the inside and through the roller fairlead. This

will ensure that there is enough space for the winch to be placed on the plate.

3. Assemble the winch on the mounting plate by pulling and turning the clutch switch to the

"DISENGAGE" position. Pull a few centimetres of cable from the drum and pass the cable loop

through the opening at the front of the mounting plate and through the roller fairlead. You may

now attach the winch to the mounting plate using the remaining screws.

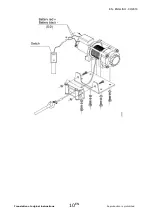

4. Connect the battery and the motor cables as shown in the diagram below. Bear in mind that

each type of winch is different.

CAUTION

Batteries contain inflammable and explosive gases. Always wear protective goggles during

installation and remove all jewellery beforehand. Do not lean over the battery while making

the different connections.

5. Attach the clevis hook to the cable: remove the pin from the hook, connect the hook to the

cable and replace the pin.

6. Always use the safety strap when winding or unwinding the cable. Using the nylon strap will

help you to keep your hands and fingers away from the drum when it is rotating.

7. Check that the drum rotates correctly. Pull and turn the clutch switch to the "DISENGAGE"

position. Manually pull out some of the cable and then, turn the clutch switch to the "ENGAGE"

position to lock the gearbox to the drum. Press the "OUT" button on the remote control. If the

drum turns and unwinds the cable, your connections are correct. If the drum turns and winds up

the cable, swap the motor connections. Repeat and check the drum rotation.

Summary of Contents for EP3500 Series

Page 2: ...EN ENGLISH 09 2019...

Page 11: ...EN ENGLISH 09 2019 Translation of original instructions 10EN Reproduction is prohibited...

Page 21: ...EN ENGLISH 09 2019 Translation of original instructions 20EN Reproduction is prohibited EP4500...

Page 23: ...EN ENGLISH 09 2019 Translation of original instructions 22EN Reproduction is prohibited...

Page 24: ......