EN - ENGLISH - 09/2019

Translation of original instructions

19

EN

Reproduction is prohibited

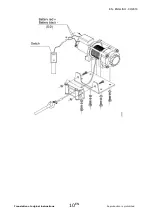

No.

Part No.

Qty

Description

1

P0350100-U

1

Motor assembly

2

P0250001

4

Lock washer Φ8

3

P0250002

4

Assembly screw, M8x15

4

P0250003

1

Transition shaft

5

P0250004

2

Coupling rod

6

P0250005

1

Hexagonal shaft

7

P0250006

1

Bushing, pre-drum

8

P0250007

6

Spring washer Φ6

9

P0250008

1

Screw, M6x8

10

P0250009

2

Assembly screw M6x70

11

P0250010

1

Drum

12

P0250011

1

Rear bearing

13

P0250012

1

Front thrust washer

14

P0250013

1

Ring gear

15

P0250200

1

Gear set

16

P0250014

1

Gearbox collar

17

P0250015

1

Trust washer

18

P0250016

1

Gearbox housing / Rear bearing

19

P0250017

1

Bearing support

20

P0250018

1

Roller bearing

21

P0250019

1

Clutch shaft

22

P0250020

1

Clutch release pin

23

P0250021

1

Spring

24

P0250022

1

Gearbox cover

25

P0250023

1

Roller bearing

26

P0250024

1

Rubber seal

27

P0250025

1

Clutch handle

28

P0250026

1

Lock washer Φ5

29

P0250027

1

Assembly screw M5x12

30

P0250028

4

Assembly screw M6x25

31

P0250029

4

Hexagonal nut, M8

32

P0250030

4

Lock washer Φ8

33

P0250031

4

Washer Φ8

34

P0250300

1

Roller fairlead

35

P0250032

1

Mounting plate

36

P0250033

2

Assembly screw M8x20

37

P0250034

2

Assembly screw M8x35

38

P0250035

1

Strap

39

P0350400

1

Cable

40

P0250036

2

Terminal protectors

43

P0350700

1

Control enclosure

Summary of Contents for EP3500 Series

Page 2: ...EN ENGLISH 09 2019...

Page 11: ...EN ENGLISH 09 2019 Translation of original instructions 10EN Reproduction is prohibited...

Page 21: ...EN ENGLISH 09 2019 Translation of original instructions 20EN Reproduction is prohibited EP4500...

Page 23: ...EN ENGLISH 09 2019 Translation of original instructions 22EN Reproduction is prohibited...

Page 24: ......