©

2011 by Huchez Treuils S.A.S.

Translation of the original instructions manual

10

UK

Reproduction prohibited

8.4 – Power supply

Before undertaking any operation on the electrical unit, check that the power supply to the

machine is off.

A disconnecting switch must be placed no more than 10 metres from the place of use.

Very important: the winch will only provide full power if the motor is supplied via a cable

section which is perfectly suited to this use.

Provide protection for individuals in front of the electrical unit.

8.4.1 – Electrical connections

The power supply cable, the protective fuses and the main disconnecting switch (see

wiring diagram) must be provided by the customer.

Check that the supply network complies with the machine.

Check the type of current; there must not be more than about 5% deviation from the

rated voltage

Neutralise electrical sources

Check that the main power supply switch on the winch is in the off position.

Do not connect the power supply cable to the machine using connection terminals (split

fittings etc.)

Do not use a cable with a smaller section to supply power to the machine. Power supply

via a generator is possible:

-

Minimum power of 3.75 kVA according to the models 250 and 400 kg.

-

Minimum power of 5,5 kVA according to the models 1000 kg.

Never "shunt" the disconnecting switches, electrical switches, prevention or limitation

equipment.

Never block, adjust or remove switches or end stops in order to go beyond the levels that

they allow.

A disconnecting switch must be placed no more than 10 metres from the place of use.

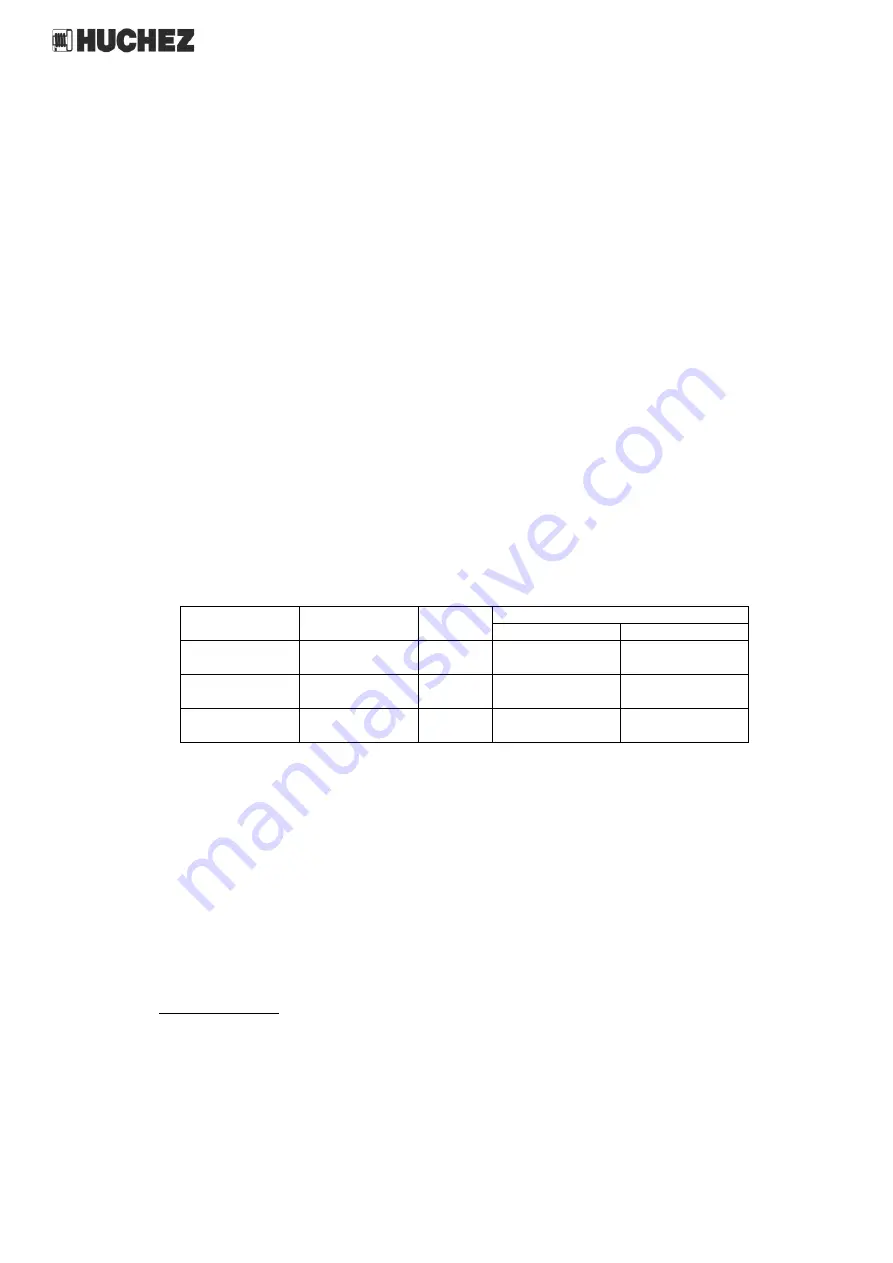

Recommended rope section:

VOLTAGE

TENSION

TYPE

Length of supply rope

10 m

30 m

230 V single

phase

230 V mono

2 + T

2.5 mm²

4 mm²

230 V three

phase

230 V tri

3 + T

4 mm²

4 mm²

400 V three

phase

400 V tri

3 + T

2.5 mm²

2.5 mm²

8.4.2 – Connection

Connect the power supply using the single phase or three phase male connector supplied

using about 0.5 m of power supply cable.

Check that the winch works (direction of rotation)

Do not change the direction labels in the control unit or in the winch's internal wiring.

8.5 – Work rope

Important: the direction of rotation of the drum depends on the way in which the machine is

connected (order of the three-phase current phases)

Reminder: check the maximum capacity of the winch

Very important:

The safety regulations require that 2 to 3 coils of rope always be left on the drum.

To comply with the legislation, the rope diameter must not exceed the recommended

diameter.

If the rope and the hook used were not supplied with the machine by the manufacturer, check

that they guarantee a level of safety corresponding to table § 6.5.

When the winch is supplied with the rope wound on, it has not been tautened during assembly.