Huck Seiltechnik GmbH • 35614 Aßlar/Berghausen • Germany

seiltechnik@huck.net • www.huck.net

\\Fileserver\text\PLAY\Play Installation Instructions\Installation Instructions 2012-2013\4540_10-01-en-010.doc

- 7 -

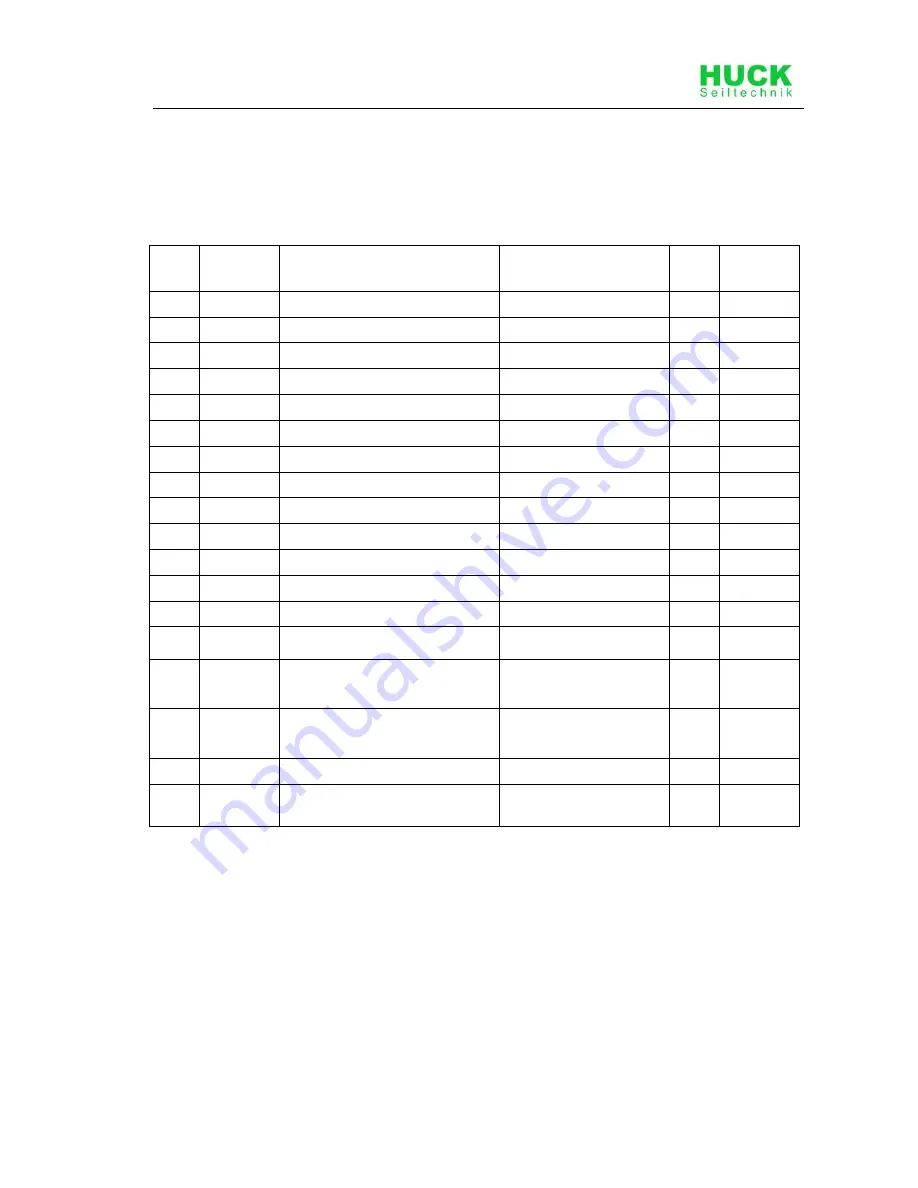

3 Delivery contents (parts list with part numbers)

3.1 In

words

Table 3-1: Delivery contents, in words

Pos. Quantity Element

/

Description

Size O.K.

Missing

1

1

Swing part

2

2

Steel post

Ø 100 mm - 2.40 m lg

100

2

Ring shackles

for Ø 100 mm

101

2

Threaded bolts

M10 x 110 mm galv.

102

4

Nut

M10 galv.

103

2

Caps

for Ø 100 mm

104

6

Self drilling pias screws

5.5 x 25 mm

105

0,33 Liter

Blue paint

107

2

Blue/yellow caps

for M12

108

2

Washer

Ø 13

109

2

Lock nut

M12, galv.

110

2

4602

M12 x 125 mm

111

2

Schackle M8

pre-assembled

112

2

Schackle cambered

Pre-assembled

113

2

PE bearing bushing

small f. M8 shackle

pre-assembled

113A

2

Hole plug

114

2

Hexagonal nut

M12

2

Sidewalk fllagstone

on site / by the customer